Description

Used Filling Monoblock OCIM 24-32-8 up to 10000 bph

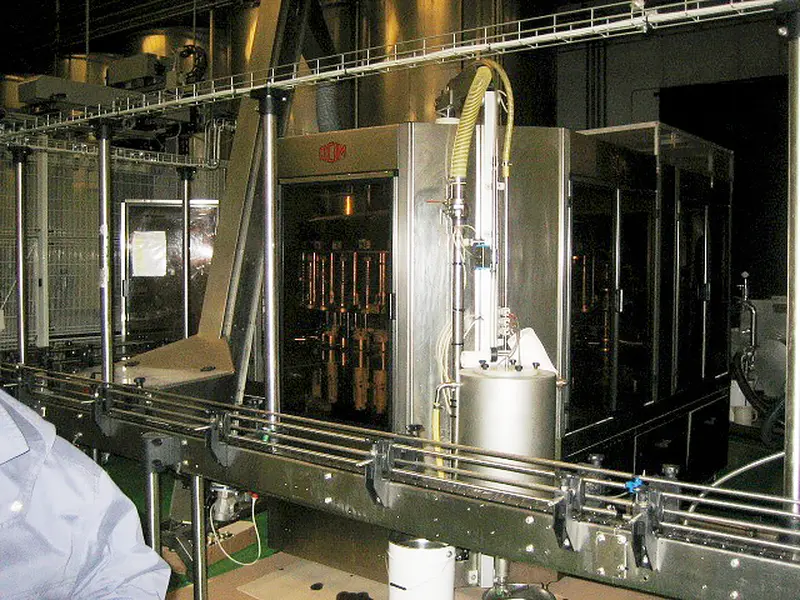

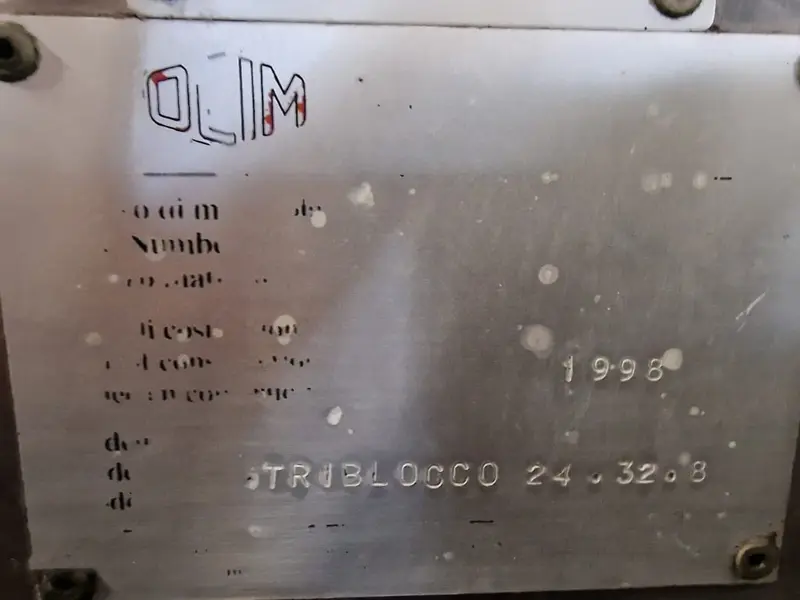

The OCIM 24-32-8 filling monoblock stands as a pinnacle in bottling technology. It offers an unparalleled capacity of up to 10000 bottles per hour. Crafted by OCIM in 1998, this machinery embodies reliability and efficiency. Specifically designed to cater to the demands of filling glass containers, particularly those housing oil products.

Technical Details

At the heart of this monoblock lies its rinser, equipped with 24 grippers meticulously engineered to ensure a secure hold on the containers. Operating with precision, the rinser utilizes compressed air for treatment, guaranteeing optimal cleanliness throughout the filling process.

Moving seamlessly to the filler, which serves as the core component of the monoblock, we encounter a marvel of engineering. Boasting 32 filling valves, this monoblock is capable of handling even the most demanding bottling tasks with ease. Whether employing gravity or a light depression technique, the filler ensures a uniform and efficient distribution of the product, thanks to its fixed nozzle design.

Completing the trifecta of functionality is the capper, a critical element in the sealing process. Configured to accommodate aluminum screw caps, the capper features 8 heads operating in harmonious synchronization, rotating clockwise to securely seal each bottle.

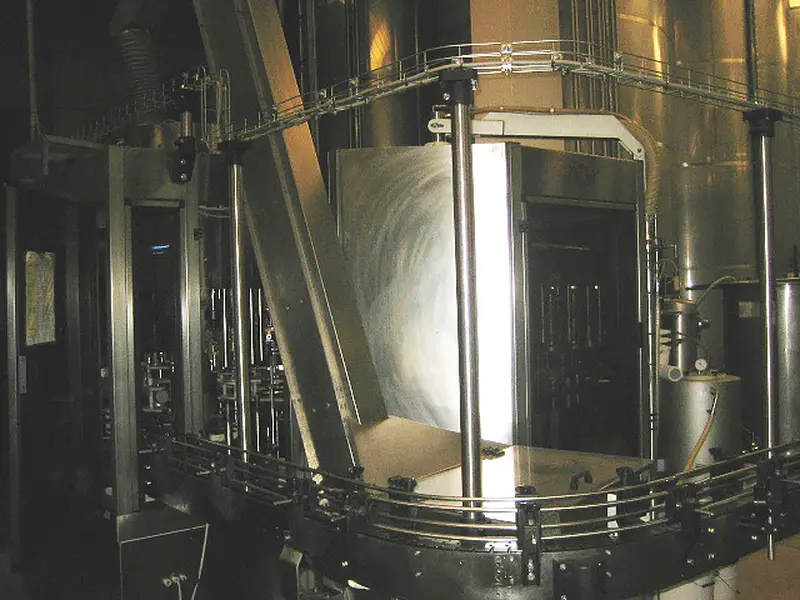

Current State and Storage

Despite its formidable capabilities, the OCIM 24-32-8 filling monoblock currently resides in storage, patiently awaiting its moment to shine. Safeguarded against the ravages of time, it stands as a testament to precision engineering. It is preserved to maintain its integrity and performance.

Application and Benefits

When deployed, this monoblock transcends mere machinery, becoming the cornerstone of efficient bottling operations. With a capacity of up to 10000 bottles per hour, it revolutionizes production processes. This enables manufacturers to meet the demands of a dynamic market with unparalleled speed and precision.

Furthermore, the OCIM 24-32-8 filling monoblock offers tangible benefits beyond its impressive throughput. Its reliability minimizes downtime, ensuring continuous operation and maximizing productivity. Moreover, its versatility allows for seamless adaptation to various bottling requirements, making it a versatile asset in the hands of discerning manufacturers.

Conclusion of the Used Filling Monoblock OCIM 24-32-8 up to 10000 bph

In conclusion, the Used Filling Monoblock OCIM 24-32-8 represents the epitome of excellence in bottling technology. With its robust construction, innovative features, and unparalleled performance, it stands as a testament to OCIM’s commitment to quality and innovation. Whether in storage or in operation, this monoblock remains a beacon of efficiency, poised to elevate bottling operations to new heights of success.