Description

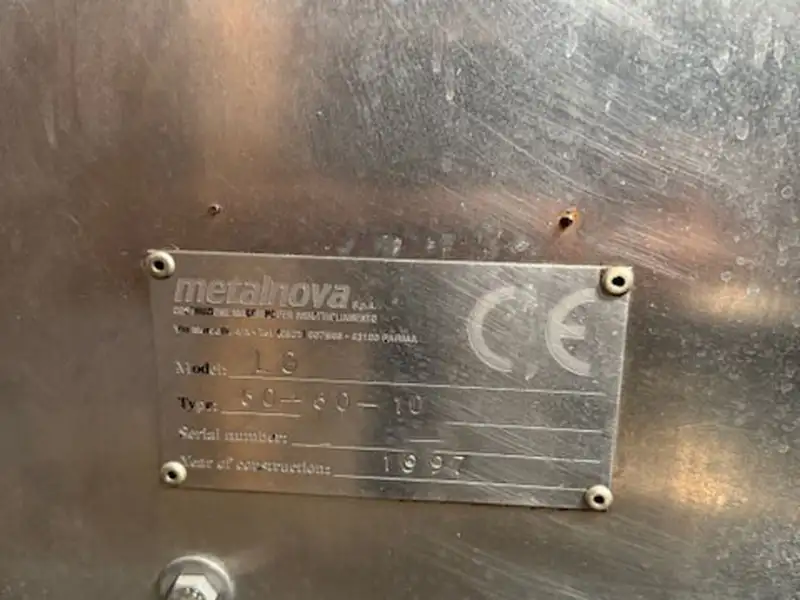

Used Filling Monoblock Metalnova for still and sparkling water 12000 bph

The Used Filling Monoblock Metalnova for still and sparkling water 12000 bph, model LG, offers a bottling solution designed to process still and sparkling water in 2-liter containers, with a production capacity of 12,000 bottles per hour. Manufactured in 1997, the machine is currently dismantled and in storage. It operates in a counterclockwise direction and supports both PET and glass containers, thereby ensuring flexibility for mixed-format bottling lines. Moreover, its design allows seamless integration into existing production environments.

Monoblock Configuration and Bottle Rinsing Process

The monoblock begins with a rinsing unit equipped with 60 grippers, which has been engineered to clean containers thoroughly before filling. Notably, the system performs two treatment phases, which not only remove impurities but also prepare each container for the subsequent filling stage. As a result, the unit maintains consistent hygiene standards while sustaining high throughput. In addition, the rinsing module integrates directly into the Used Filling Monoblock Metalnova for still and sparkling water 12000 bph, thereby ensuring accurate container positioning for downstream operations.

Isobaric Filling System with Traditional Valve Technology

At the core of the Used Filling Monoblock Metalnova for still and sparkling water 12000 bph lies an isobaric filler equipped with 60 valves. The system, in particular, uses traditional isobaric valves, which allow the machine to accurately manage both carbonated and non-carbonated liquids. Consequently, it maintains pressure stability throughout the entire filling process. In doing so, it minimizes foam generation and preserves CO₂ in sparkling beverages. Furthermore, this configuration makes the filler suitable for dual-function production lines that handle a wide range of water products with precision and efficiency.

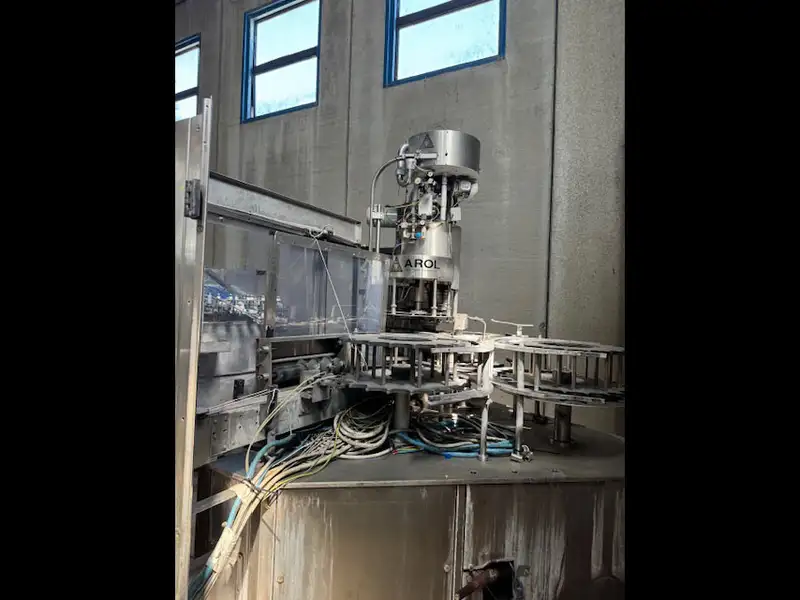

AROL Capper with Three-Roller Threading System for Plastic Screw Caps

Following the filling phase, the AROL capping unit applies plastic screw caps using a three-roller threading mechanism (“3 principles Alaska”). This component includes 10 heads, each engineered to ensure uniform closure at high speeds. More specifically, the “3 principles” system uses three threading rollers to apply consistent torque and secure sealing. Thus, the capper guarantees reliable performance across various formats and cap types. It is especially effective for high-volume operations. Additionally, it aligns perfectly with the performance characteristics of the Used Filling Monoblock Metalnova for still and sparkling water 12000 bph, maintaining closure accuracy and product integrity.

Electronic Control and Spare Parts Availability

The machine uses a Siemens PLC to control its various operational stages. This platform not only ensures system stability but also allows for easy diagnostics and interface integration. Besides that, built-in safety features ensure compliance with modern industry standards and operational security. What’s more, the Used Filling Monoblock Metalnova for still and sparkling water 12000 bph comes with a set of available spare parts, which greatly facilitates both routine maintenance and emergency repairs. Therefore, operators can reduce unplanned downtime and extend equipment life without the need for complex interventions.