Description

Used filling monoblock FIMER 24/28 / 6s

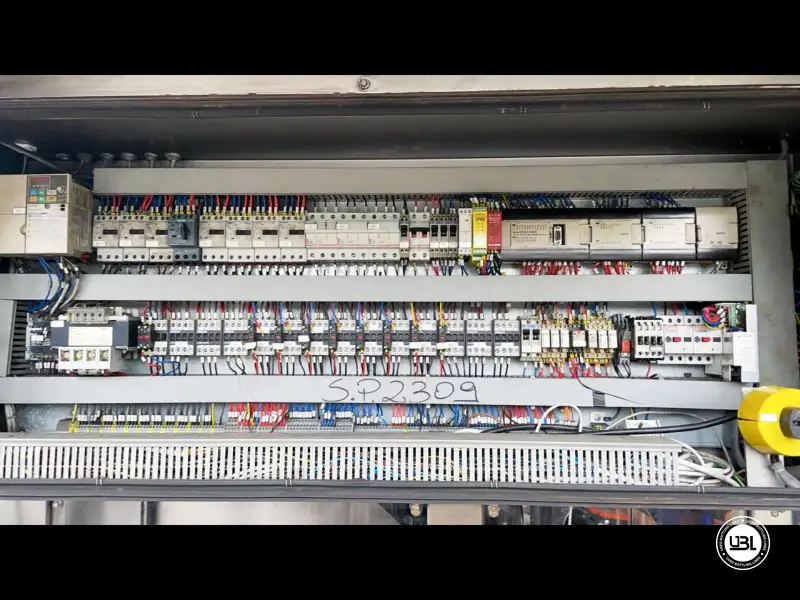

This wine filler has 24 rinsing clamps, 28 GT filling nozzles and a 6 head Arol corking machine. The machine has recently gone through complete maintenance. It features also a vacuum pump and new water casings.

It has 6 different formats to fill different bottles of wine. From 375, 750 and 1500.

The rinser stations have a simple system for letting water into the bottle, and use single treatment. The pitch of the used filling monoblock allows the processing of bottles up to 1,5 L, making it very versatile.

Specifications:

The still wine filler works with slight depression and therefore fills non-carbonated liquids.

These can be still wines or non-carbonated soft drinks, juices if their maximum thickness doesn’t exceed about 18%. The capper is a straight cork suitable for the diameter 28 necks.

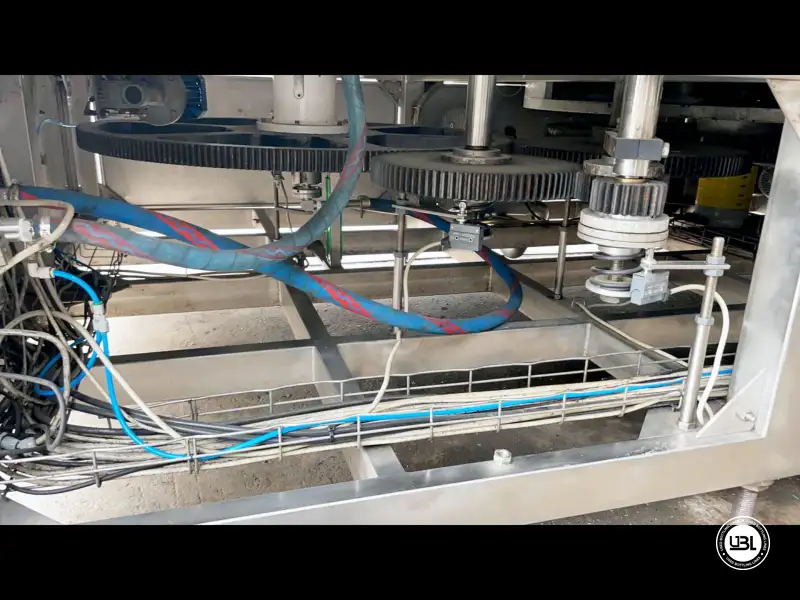

The still wine filler on the underside of the gears is functional. No particular problems or wear is therefore detected on the used filling monoblock.

To transport the machine, a normal truck is required to also place the various equipment on other pallets.

The Fimer used monoblock represents a valid alternative because of its efficiency and ease of use.

This is true for a number of reasons, such as: the ease with which the filling valves can be disassembled and serviced and the easy-to-use rinsing pliers.

In the case of this type of machine, the term monoblock identifies the following functions:

Rinsing, filling, capping and labeling if requested or provided / designed by the customer.

The advantages that a monoblock has, compared to separate machines connected to each other by conveyor belts, are: reduction of occupied space, optimization of personnel and energy consumption, perfect synchronization between the various machines, absolute efficiency.