Description

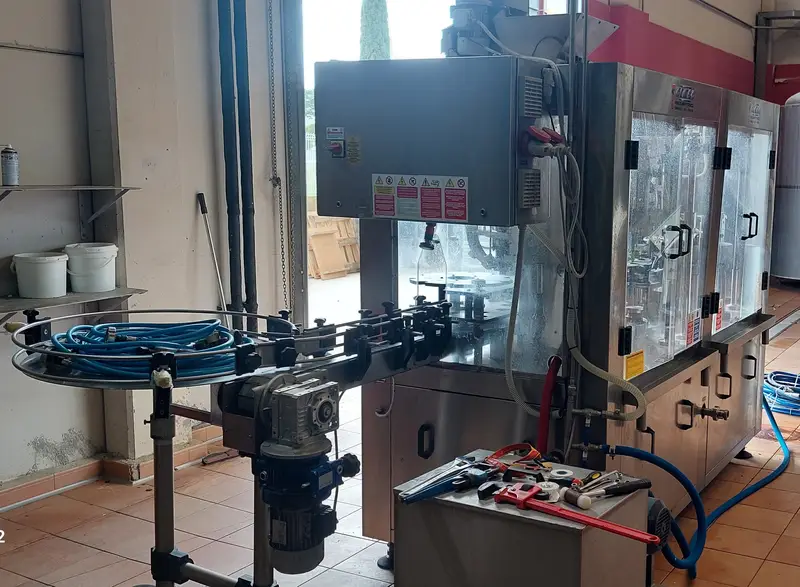

Used Filling Monoblock Cimec America

The Used Filling Monoblock Cimec America model DPS 6/6/1C is an advanced isobaric bottling solution designed for the precise rinsing, filling, and capping of carbonated beverages. Engineered with industrial-grade stainless steel and based on a robust mechanical architecture, this monoblock is tailored for small to medium-sized beverage operations seeking reliability, hygiene, and consistent process control.

This CIMEC monoblock integrates three essential stations into a compact, fully automatic system. The configuration includes a bottle rinsing unit, an isobaric filling carousel, and a crown capping station, all enclosed within stainless steel safety guards with transparent access doors for operational monitoring and safety compliance.

Isobaric Filling Technology and Construction

At the heart of the Used Filling Monoblock Cimec America is its isobaric filling carousel, specifically engineered for carbonated liquids such as beer, sparkling wine, kombucha, cider, and similar beverages requiring careful handling to preserve carbonation and minimize product loss. The filling station features stainless steel isobaric valves connected to a pressurized product tank, ensuring precise equalization between the internal bottle pressure and the product tank before the filling cycle begins.

The isobaric filling method is characterized by maintaining a constant counter-pressure using CO₂ or other inert gases. This technology allows the product to enter the bottle under pressure, minimizing the formation of foam and the risk of de-gassing, which is critical for carbonated drinks. Filling is performed at a controlled rate, typically using a “level” principle where the filling valve shuts off when the liquid reaches a predefined height within the bottle, guided by dedicated overflow tubes.

All product-contact surfaces are manufactured from high-quality AISI 304 stainless steel, ensuring full compliance with sanitary standards required in the food and beverage industry. The filling station is equipped with pressure gauges and safety valves, allowing for fine-tuned process adjustments and safeguarding both the operator and the product.

The system accepts a range of bottle sizes from 0.22 liters up to 1.5 liters, providing operational flexibility for various production formats. Changeover between bottle sizes is managed manually, with adjustable guides and supports. The monoblock is configured for crown cap application (26 mm diameter), using a dedicated capping turret with mechanical sorting and feeding of the crowns. The design enables precise and secure sealing, vital for maintaining carbonation and product integrity.

Automation, Utility Requirements, and Operational Safety

This Used Filling Monoblock Cimec America operates as a fully automated rotary triblock, requiring minimal manual intervention during normal production cycles. Mechanical synchronization ensures seamless bottle transfer between stations, supported by motor-driven conveyors and rotary starwheels for accurate positioning throughout rinsing, filling, and capping.

The machine is powered by a three-phase electrical system (400V + N + T), with an installed power of 80 kW, supporting all drive motors, pneumatic controls, and auxiliary systems. Pneumatic requirements are managed via integrated solenoid valves and air lines, operating within a working pressure range of 1 to 8 bar. The equipment is also prepared for connection to a CO₂ or other counterpressure gas supply, required for the isobaric filling operation.

Safety is a core feature of the monoblock’s design. All moving components are fully enclosed by stainless steel panels and polycarbonate windows, equipped with interlock switches on access doors to immediately stop the machine in case of unauthorized opening. Emergency stop buttons are positioned for immediate operator access, and cable routing is managed internally for both hygiene and safety.

Operation and process control are performed via a classic control panel located on the machine’s side, featuring physical pushbuttons, selectors, and signal lights. The control interface allows for start/stop functions, emergency stops, and manual overrides, in line with standard practices for reliable mechanical bottling equipment.

Bottling Process and Maintenance Features

The rinsing station utilizes stainless steel gripping clamps to invert each bottle, exposing the interior to a dedicated spray nozzle for thorough washing with water or a sanitizing solution. Waste water is collected in a dedicated drain tray positioned below the rinsing turret, preventing cross-contamination with the production area.

Bottles then transfer automatically to the filling carousel, where the isobaric process takes place. Each valve is engineered for smooth, consistent operation, minimizing turbulence and product agitation. Fine adjustment mechanisms allow for manual tuning of fill height and pressure settings, accommodating variations in bottle format or beverage carbonation levels.

Following filling, bottles are conveyed to the capping station. Here, crown caps are sorted and fed by a mechanical channel to the capping head, which precisely places and seals each cap with controlled force. The robust design of the capping turret ensures reliable operation and repeatability over long production runs.

Maintenance access is facilitated by the monoblock’s open-frame base and wide, clear access doors. Drive motors and gearboxes are mounted on the lower section of the frame, easily reachable for inspection or replacement. Lubrication points, valve connections, and utility lines are laid out logically for straightforward service and preventative maintenance.

Cleaning-in-place (CIP) routines can be performed through dedicated inlet and drain connections on the product tank and filling circuit, although all adjustments and format changes are managed manually. The design philosophy favors mechanical reliability and ease of use, with no reliance on complex electronics or touch-screen controls.

The Used Filling Monoblock Cimec America DPS 6/6/1C represents a reliable, technically mature solution for small to mid-sized beverage producers who require consistent, high-quality bottling of carbonated products. The integration of isobaric technology, robust mechanical automation, and user-oriented maintenance features ensure that the system provides dependable service and superior beverage integrity across a range of formats and applications. This monoblock is ideal for operations where process repeatability, hygiene, and product preservation are of primary importance, all within a compact and accessible industrial package.