Description

Used filling monoblock AMS FERRARI 12/12/1 year 2014

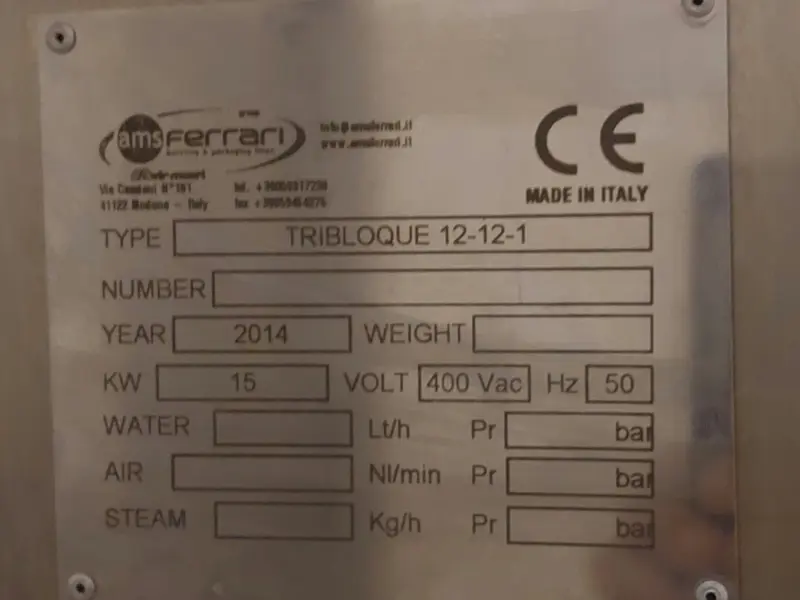

The Used filling monoblock AMS FERRARI 12/12/1 year 2014 delivers a compact, integrated isobaric bottling solution for beer production in glass bottles. AMS FERRARI manufactured this model in 2014 and designed it to combine rinsing, filling, and capping into a single mechanical unit. As a result, this configuration reduces handling times and optimizes floor space in medium-scale bottling facilities.

Mechanical and production configuration

The Used filling monoblock AMS FERRARI 12/12/1 year 2014 includes 12 rinsing grippers, 12 filling valves, and a capping module with two heads. The machine processes containers ranging from 0.33 to 1 liter in a clockwise rotation. Consequently, it suits a variety of bottle formats common in beer packaging. It operates at a nominal speed of 1,800 bottles per hour. Moreover, the system provides a stable and continuous workflow for consistent production output.

Operators disassembled the machine after it ran for approximately 200 hours, during which it bottled around 300,000 liters. Due to its low usage, the equipment shows minimal mechanical wear and preserves the integrity of key components. Production teams can, therefore, integrate this equipment into existing lines or use it as the base for new installations. In both cases, the monoblock ensures mechanical uniformity and high reliability.

Rinsing section

The rinsing module on the Used filling monoblock AMS FERRARI 12/12/1 year 2014 uses 12 mechanical grippers to handle the bottles. The system performs two rinsing treatments, ensuring internal sanitization before filling. In addition, the grippers support both 0.33 and 0.75 liter glass bottles, which makes the machine suitable for a wide range of beer formats. Thus, the rinsing system contributes to maintaining hygiene standards across all packaging sizes.

Filling section

The filling section uses 12 traditional isobaric valves with mobile nozzles. The system maintains pressure balance during filling and minimizes foam generation or CO₂ loss. This feature, in turn, protects product quality and prevents waste. Furthermore, the mechanical design ensures ease of cleaning and straightforward maintenance. These characteristics make the equipment ideal for beer bottling, where pressure control directly influences final product consistency.

Operators rely on the mobile nozzle configuration to handle bottle variations with minimal adjustment. Also, the isobaric valves support repeatability across extended production cycles. Altogether, these features improve filling performance while maintaining operational efficiency.

Capping section

The capping module of the Used filling monoblock AMS FERRARI 12/12/1 year 2014 applies crown caps using two heads. The system supports both 26 mm and 29 mm caps and uses mechanical force to seal each bottle with consistent pressure. Unlike electronic systems, this mechanical configuration simplifies service and ensures predictable performance.

The machine excludes any aseptic configuration, which limits its use to non-sterile environments. Nevertheless, breweries operating under standard hygiene protocols can easily incorporate it into their process. Hence, the capping unit fits many common production needs.

Physical specifications and installation

The Used filling monoblock AMS FERRARI 12/12/1 year 2014 weighs approximately 2,500 kg. Although the system’s electrical specifications and dimensions are not listed, its compact frame simplifies transport and on-site assembly. As such, operators can relocate and install the unit without requiring specialized lifting equipment.

In particular, the monoblock’s modular structure supports flexible placement within a bottling line. Thus, technicians can adapt the layout to specific plant configurations.

Technical conclusion

The Used filling monoblock AMS FERRARI 12/12/1 year 2014 offers a reliable and low-wear solution for small and medium-scale beer bottling. Its integrated rinsing, filling, and capping structure ensures mechanical precision and operational efficiency. Because of this, breweries can preserve product quality, reduce space requirements, and lower capital investment compared to purchasing new equipment.

To summarize, the monoblock suits breweries that seek durability, accuracy, and cost-effective integration. In conclusion, the Used filling monoblock AMS FERRARI 12/12/1 year 2014 meets technical expectations for dependable beer bottling operations.