Description

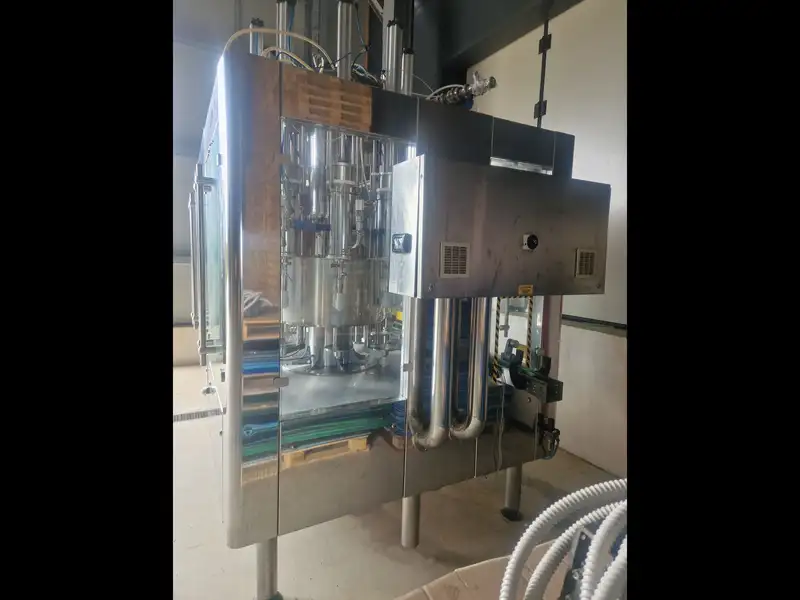

Used Filling Monoblock Alfatek for olive oil 1500 bph

General Features of the Used Filling Monoblock Alfatek for Olive Oil 1500 BPH

The ALFATEK MBV 9/1 VOLUMETRICA SABRY filling monoblock, built in 2013, offers an efficient and reliable solution for bottling edible oil. It operates at a speed of 1500 bottles per hour, with clockwise rotation and a fully automated workflow. In fact, the machine currently runs in active production, having completed approximately 1700 operating hours. Moreover, it includes all safety protections, user manuals.

Container Compatibility and Supported Formats

The Used Filling Monoblock Alfatek for Olive Oil 1500 BPH handles a wide variety of containers. Specifically, it works with both PET bottles and metal cans, supporting the following formats:

-

PET 138x138xh253 mm

-

PET 148x148xh320 mm

-

PET 81x81xh236 mm

-

PET 63x63xh184 mm

-

Cans 150x92xh192 mm

-

Cans 150x92xh261 mm

-

Cans 149x120xh315 mm

Consequently, the machine adapts easily to diverse packaging needs. Whether the production involves small household bottles or larger industrial formats, this monoblock provides the required flexibility. Additionally, this versatility reduces the need for multiple machines, optimizing both space and investment.

Filling Section: Volumetric Technology

The filling section of the Used Filling Monoblock Alfatek for Olive Oil 1500 BPH uses 9 volumetric valves. These valves deliver accurate and repeatable dosing, which is especially important for high-viscosity products like olive oil. Notably, the system uses fixed valves and operates in a non-isobaric configuration. Therefore, it suits still liquids and avoids the complexities associated with pressurized systems. Furthermore, the volumetric method helps maintain product integrity while minimizing waste and overfill.

Press-On Capping: Compatibility and Sizes

The machine applies plastic press-on caps using one capping head, which supports multiple cap dimensions:

-

Ø51.5 x 23 mm

-

Ø37.5 x 22 mm

-

Ø38 x 20 mm

Because it handles non-threaded necks, the monoblock accommodates a wide range of container shapes typically used for edible oil. Additionally, the press-on capping system simplifies maintenance and allows for fast format changes. As a result, it ensures both high efficiency and reliable sealing performance. In short, it delivers consistent closure without the need for threading or torque control.

Output per Format and Electrical Specifications

Depending on the bottle size, the Used Filling Monoblock Alfatek for Olive Oil 1500 BPH achieves varying output rates:

-

2000 bph for 0.5L and 1L

-

1500 bph for 2L

-

1400 bph for 3L

-

1200 bph for 4L

-

1000 bph for 5L

Thus, the machine performs efficiently across all common olive oil packaging formats. In terms of power, it operates on 415 Volts and 50 Hz, complying with industrial electrical standards. Despite its robust capabilities, the monoblock weighs only 300 kg, making it compact enough for mid-scale facilities. Moreover, its design facilitates both installation and relocation when needed.