Description

Used filling machine TBA21 500 Prisma 8000 bph

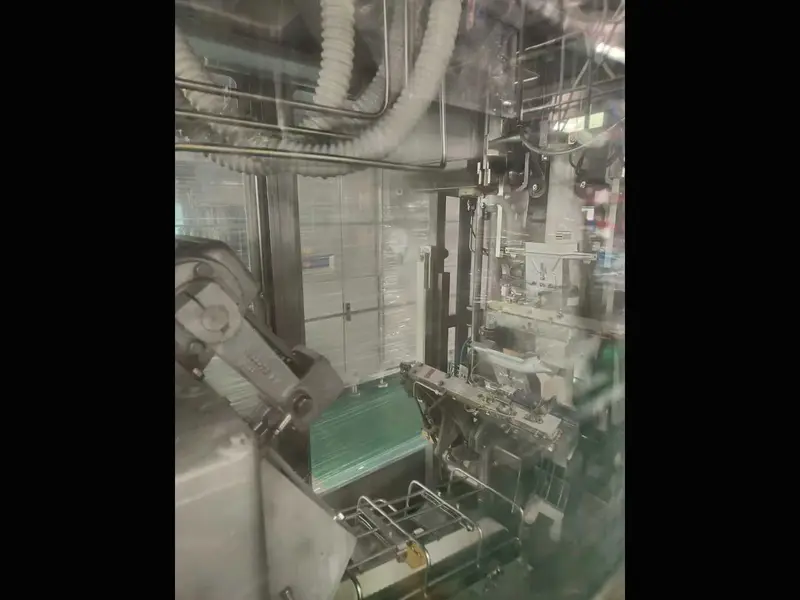

The Used filling machine TBA21 500 Prisma 8000 bph provides a high-efficiency solution for industrial aseptic filling. Tetra Pak specifically designed this machine to package dairy products and fruit juices in Prisma Brik containers of 0.50 L. As a result, it ensures a reliable and consistent filling process.

Technical features of the Used filling machine TBA21 500 Prisma 8000 bph

The TBA21 model, built in 2003, undergoes a complete refurbishment before delivery. Consequently, this process restores its original functionality and ensures compliance with current safety standards. The machine currently remains in storage; however, it is ready for installation.

Aseptic filling system

This machine uses aseptic technology to protect the product throughout the bottling process. More importantly, it preserves the microbiological integrity of the liquid without requiring additional preservatives. Therefore, it extends shelf life while maintaining the product’s organoleptic properties. For this reason, manufacturers can ensure both safety and quality.

Production capacity and compatibility

The machine fills up to 8,000 bottles per hour (bph). Thus, it becomes an ideal solution for medium- to high-volume production. It works with Prisma Brik containers of 0.50 L. In addition, it ensures efficient operation in dairy and fruit juice packaging. Furthermore, this model optimizes production speed while maintaining precision.

Reliability and operational safety

The machine features an advanced safety system that complies with all current regulations. Specifically, it includes protective devices that minimize operational risks. In particular, engineers inspect each component to verify its structural integrity and ensure proper functionality. Moreover, they evaluate its reliability to guarantee long-term efficiency.

Maintenance and refurbishment

Before delivery, technicians conduct a full inspection of the Used filling machine TBA21 500 Prisma 8000 bph. To begin with, they assess the overall condition of the system. Then, they replace worn components and perform a final test to confirm proper operation. Notably, the refurbishment process includes checking pneumatic circuits, replacing seals, inspecting filling pumps, and calibrating the sterilization system. Additionally, they ensure that all safety features remain fully functional. By doing so, they restore the machine’s performance to optimal levels.

Conclusion of the Used filler Tetra pak 500 Prisma

This filler delivers a reliable and efficient solution for aseptic packaging in Prisma Brik containers of 0.50 L. As a result, it meets the demands of dairy and juice manufacturers seeking precision and high output. At the same time, its safety features provide added security during operation. Most importantly, its high productivity and dependability make it an excellent choice for industrial use. With that in mind, a full refurbishment before delivery guarantees optimal performance and compliance with industry standards.