Description

Used filling line for milk PET bottles and yoghurt in glass jars 2005

This line includes a Weightpack filling monoblock, model WET 8-8-4-282. Notably, engineers built this system in 2005 to ensure high operational efficiency and precise dairy product filling. Consequently, the line fills 2500 PET bottles with milk and 4500 yoghurt jars of 125 g per cycle.

Filling system specifications

First of all, the filling monoblock operates with specific formats: 0.5 L and 1.0 L PET bottles for milk, and 125 g glass jars for yoghurt. Furthermore, the machine features safety protections to ensure operator safety during bottling.

In addition, the filling process utilizes a rinser with 8 grippers and an ozone treatment to sanitize containers. Moreover, the filler uses 6 heads with gravity filling technology and mobile nozzles to optimize product flow and minimize contamination risk.

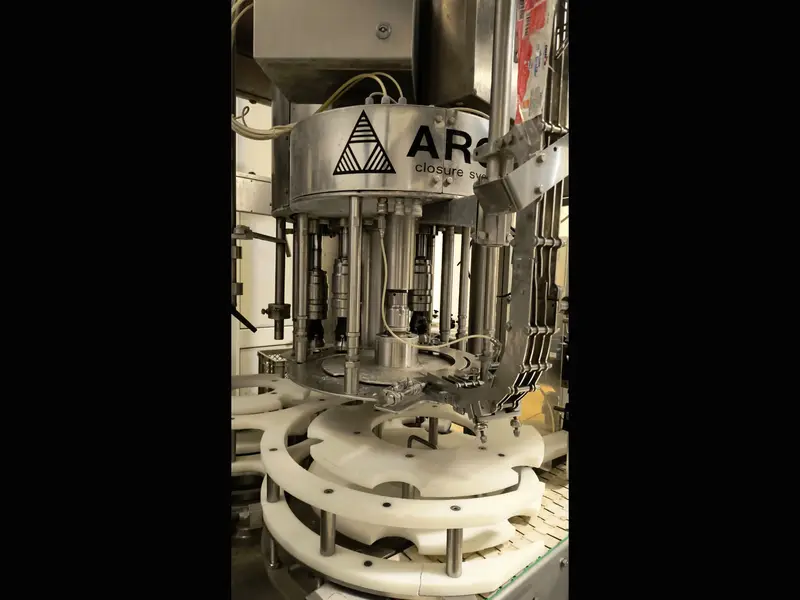

Two different types of caps are used. A 38 mm screw cap suitable for PET bottles of various sizes. Alternatively, by changing the capping machine head, it uses a press-on cap. In this case, it is a 56 mm cap suitable for glass jars.

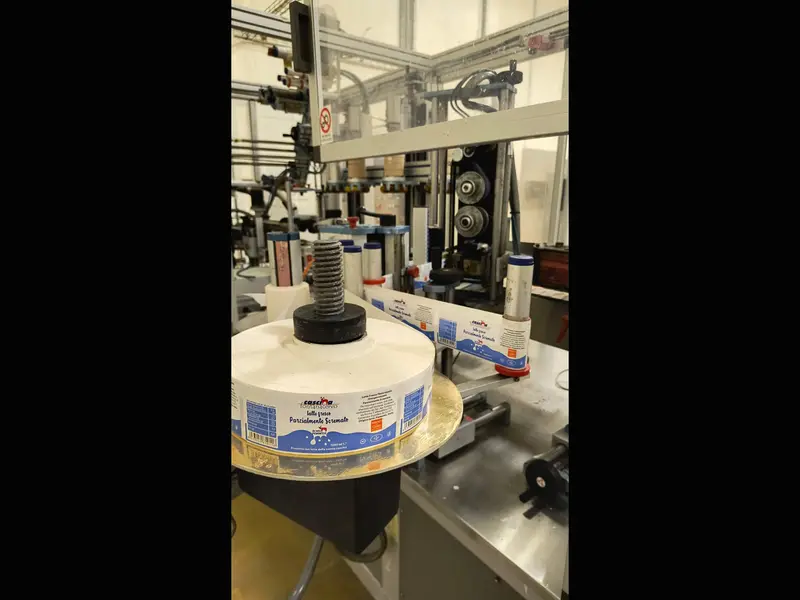

Labeling system in the Bottling line for milk and yogurt

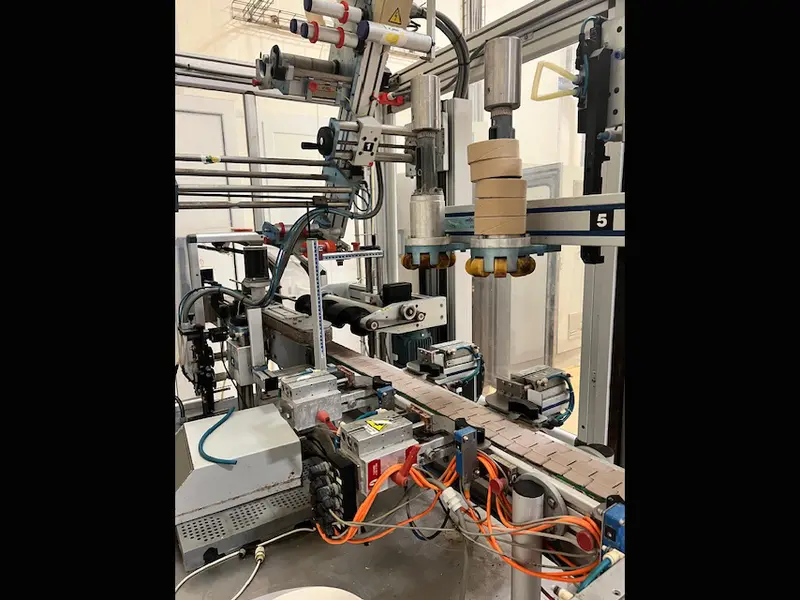

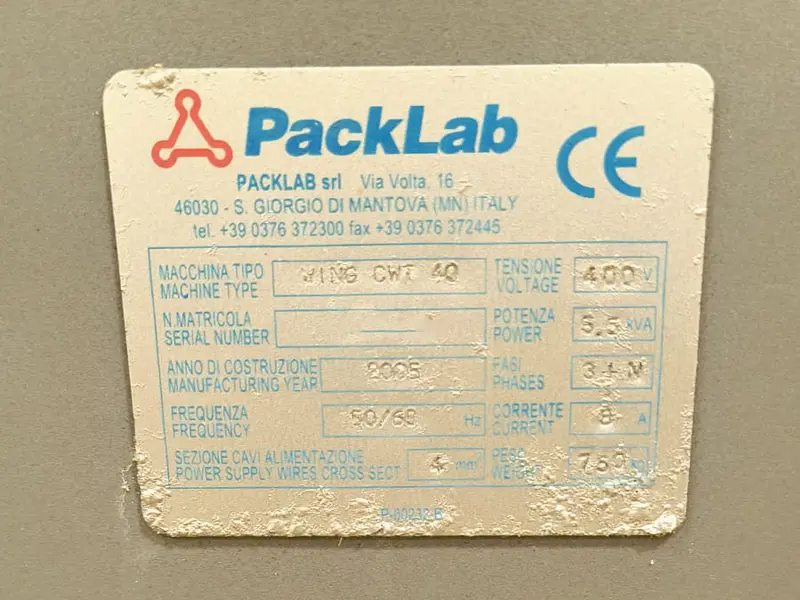

Similarly, the installed labeler, a Packlab model WINC CWT 40 from 2005, includes safety protections and applies self-adhesive labels. Specifically, a photoelectric centering system ensures precise label placement on containers. Additionally, operators manually adjust the application head to accommodate format variations. Notably, a Siemens PLC manages the entire process, ensuring reliable and consistent operation.

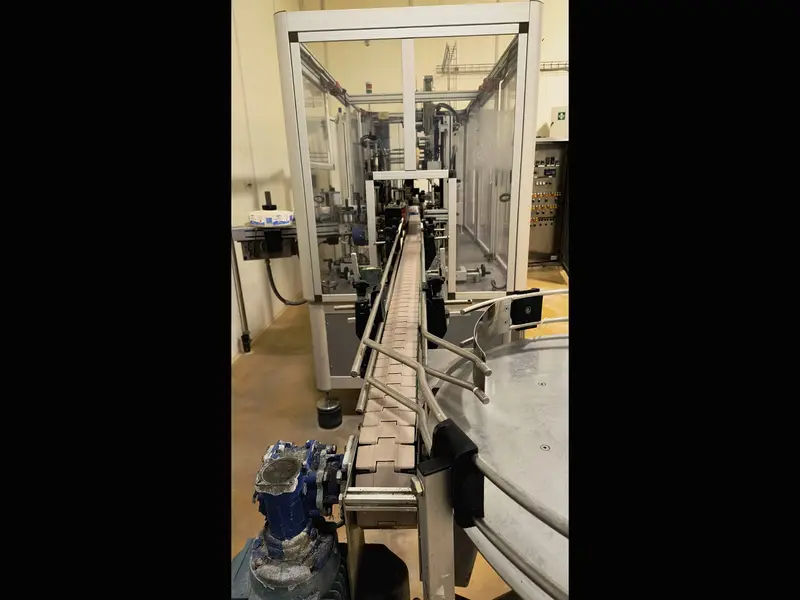

Additional line features

Equally important, the used filling line for milk in PET bottles and yoghurt in glass jars year 2005 includes a final accumulation table, maintaining a continuous production flow and reducing machine downtime. Consequently, the system remains fully operational, ready for installation and immediate use.

Conclusion of the Bottling line for milk and yogurt

Given these points, with its configuration and advanced technical features, this line provides an efficient solution for milk and yoghurt production while maintaining high hygiene, safety, and precision standards. In particular, ozone sanitization systems, gravity filling units, and reliable automation components make it a suitable choice for dairy production environments requiring high quality and productivity. Furthermore, these features contribute to long-term reliability and efficiency