Description

Used filling line for beer in cans 25000 cph

The used filling line for beer in cans 25000 cph delivers high-speed beer canning across multiple formats. Specifically, it fills 500 ml, 440 ml, and 330 ml cans with standard 202 lids, consistently reaching a capacity of 25,000 cans per hour. Although the line remains installed, it is currently not operational. Nevertheless, all components remain in excellent working condition.

Empty can feeding system

To begin with, a Linker DPG-500 depalletizer, built in 2012, unloads empty cans at the start of the line. Subsequently, rope conveyors from Linker (model RC/KHS, 2012) transport the cans to a Triplexrinser TR/KHS rinser, also from 2012. In this section, the system moves cans smoothly and prepares them efficiently for the next stage. As a result, the line ensures gentle handling while maintaining productivity.

Filling and seaming

Next, the KHS Innofill DVD 60 filler, installed in 2017, performs the filling process using 60 dedicated valves. In parallel, a Ferrum F08 seamer seals the cans, while an NSM 30A lid feeder supplies lids with precision. Consequently, this configuration ensures accurate dosing and secure sealing at high throughput. Notably, the filling and seaming block is among the most recent upgrades to the line.

Pasteurization and quality control

After sealing, the product passes through a KHS Innopro KZE flash pasteurizer, installed in 2017. Additionally, this unit includes a 5000-liter buffer tank to stabilize the process. Meanwhile, a KHS Innocheck fill level inspector (2012) continuously monitors the liquid level in each can. In doing so, it guarantees compliance with rigorous quality standards. Therefore, the pasteurization and inspection phases preserve both safety and consistency.

Secondary packaging and handle application

Once the cans are processed, a KHS Innopack Kisters SP 050 B2 multipack packer (2012) wraps them using shrink film—either printed or transparent. It operates on a double-lane system at 50 cycles per minute. Moreover, a KHS CSM 050-02 handle applicator (2011) applies handles at the same speed, which facilitates later transport. In other words, the secondary packaging setup optimizes the line for retail and logistics needs.

Tray packing and shrink wrapping

Following multipacking, the line uses a KHS Innopack Kisters TP 035 B2 tray packer (2012) to place packs into trays at 35 cycles per minute. Then, a KHS Innopack Kisters FS-AL shrink wrapper (2017) applies shrink film to stabilize the load. Thus, the packs remain secure and compact throughout distribution. Furthermore, both machines maintain high reliability under continuous operation.

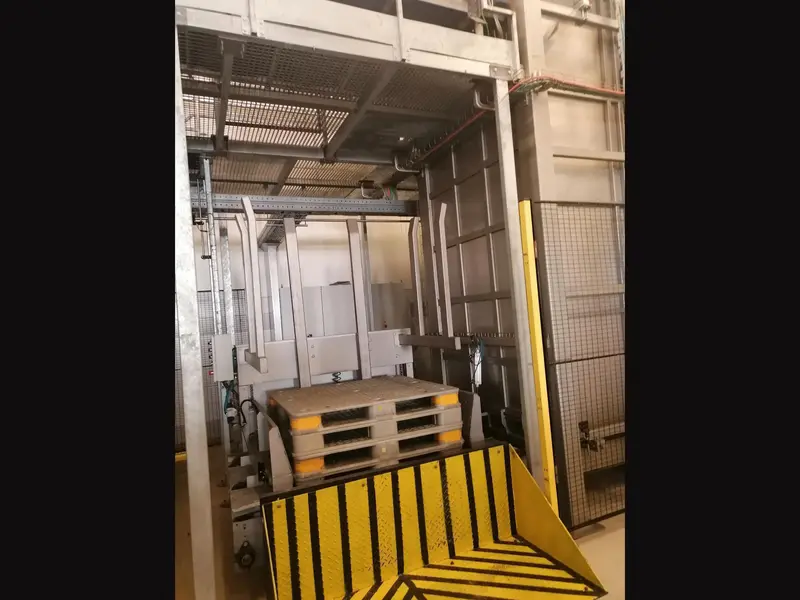

Palletizing and end-of-line operations

At the end of the line, a KHS Innopal MPH 1-1 palletizer (2012) stacks trays without using interlayers. This simplifies the palletizing process while saving materials. Subsequently, a Fiat MFP pallet wrapper (2017) secures the stacked trays with stretch film. Finally, an Erpin EZP labeler (2018) applies identification labels for traceability and inventory tracking. Together, these final stages complete the packaging cycle.

Conveying systems

Throughout the entire line, conveying systems efficiently transport empty cans, filled cans, packed units, and pallets. Thanks to these integrated conveyors, the used filling line for beer in cans 25000 cph maintains a seamless and automated production flow. Consequently, the line meets the demands of high-volume beer producers seeking reliable and well-maintained equipment.