Description

Used filling line for beer GAI up to 900 bph year 2017

The used filling line for beer GAI up to 900 bph, year 2017, delivers a highly efficient and precise technical solution for the bottling sector. Furthermore, this Filling line for beer GAI ensures high performance and adapts to various production needs, meeting the highest quality standards required by industry operators.

Main technical features of the Filling line for beer GAI

The Filling line for beer GAI operates at a speed of 900 bottles per hour (BPH), which optimizes medium productions. Moreover, the glass bottles support formats of 0.33 L, 0.50 L, and 0.70 L. This system processes beer using isobaric filling, thereby preserving the product’s organoleptic characteristics with precision.

The labeling process precedes filling, thus enhancing efficiency and order in the production line while simultaneously optimizing operational flow.

Filling monoblock

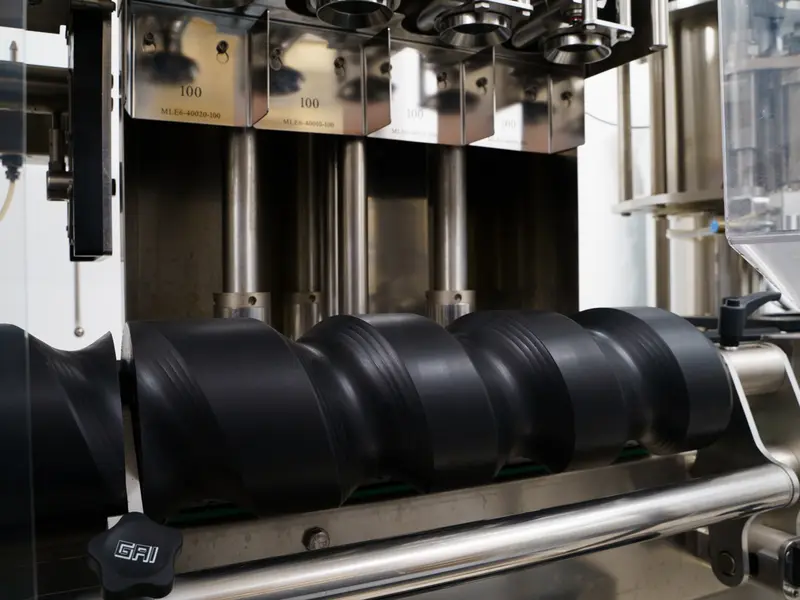

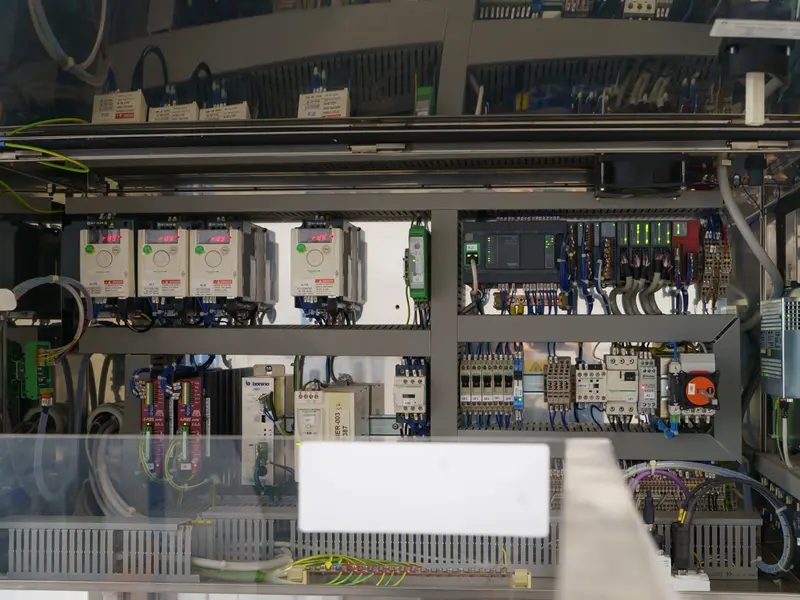

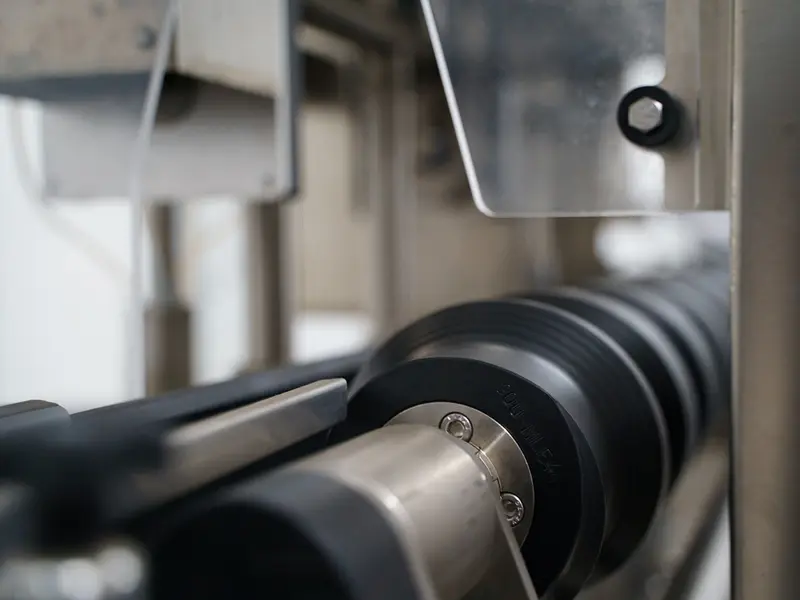

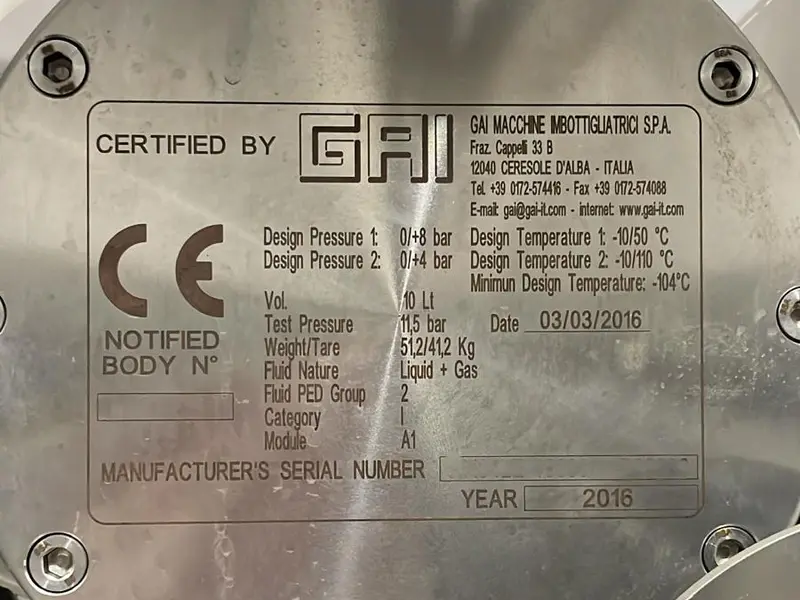

The GAI MLE441-BIER-003 filling monoblock, built in 2017, integrates several essential functions for the bottling process:

- 4 rinsing grippers prepare and sanitize the bottles.

- 4 filling valves deliver precise and rapid dosing.

- 1 capping head accommodates caps measuring 26.5×5.9.

The monoblock measures 3650 mm in length, 1300 mm in width, and 2200 mm in height. Additionally, it consumes 6 kW of electricity, operates at 400 Volts, and runs at a frequency of 50 Hz. Therefore, this technical profile supports flexible installation compatible with standard industry infrastructure.

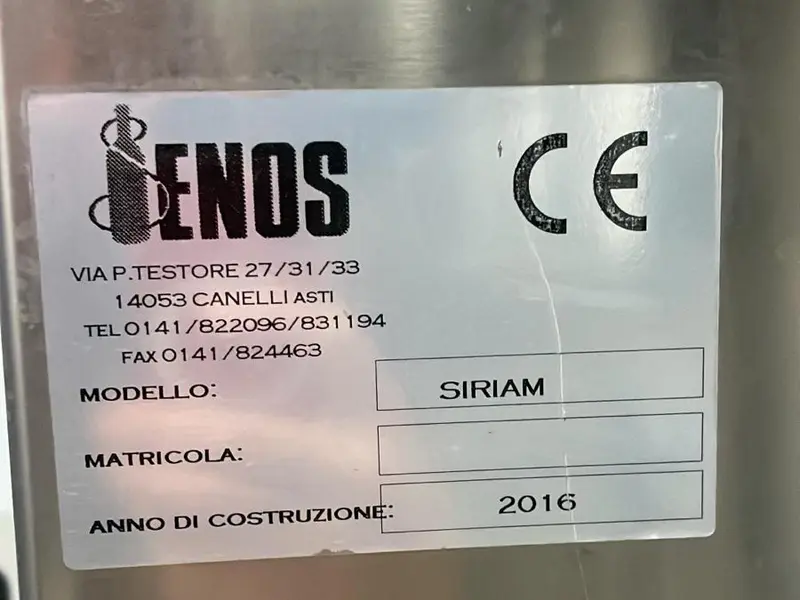

Labeling machine in the Filling line for beer GAI

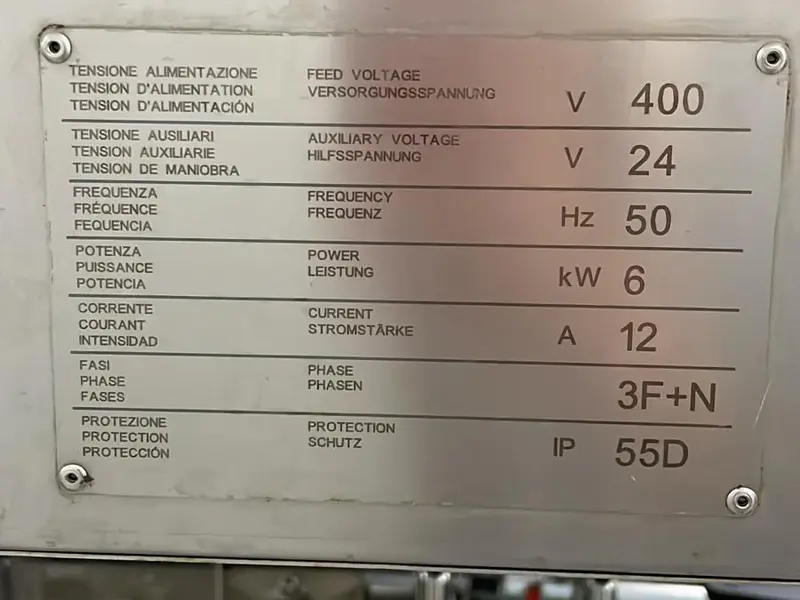

The Enos SIRIAM labeling machine, from 2016, applies labels to the front and rear of bottles using a linear system. Furthermore, the automatic glue level adjustment system utilizes rollers for precision.

The optical centering system, based on photoelectric technology, applies labels accurately. In addition, the electronically managed head adjustment allows for quick and reliable configuration.

The labeling machine measures 2405 mm in length, 2200 mm in width, and 1690 mm in height. It also consumes electricity at 400 Volts and operates at a frequency of 50 Hz.

Operational state and advantages

The Filling line for beer GAI operates effectively and integrates seamlessly into an existing production line or constitutes a new one. Moreover, the GAI monoblock and Enos labeling machine work together to create a smooth production process, minimizing downtime and maximizing productivity.

This line serves breweries requiring a compact, reliable, and high-performing solution. Likewise, its technical configuration handles various types of bottles and products, offering great production versatility.

Conclusion

The used filling line for beer GAI up to 900 bph, year 2017, provides an excellent option for those seeking reliable and high-performing equipment. Its technical features and operational state enable immediate implementation, thereby addressing the efficiency and quality needs of the current market.