Description

Used Rotary Filler–Capper Monoblock 24/8 for PET and HDPE Bottles – Overview

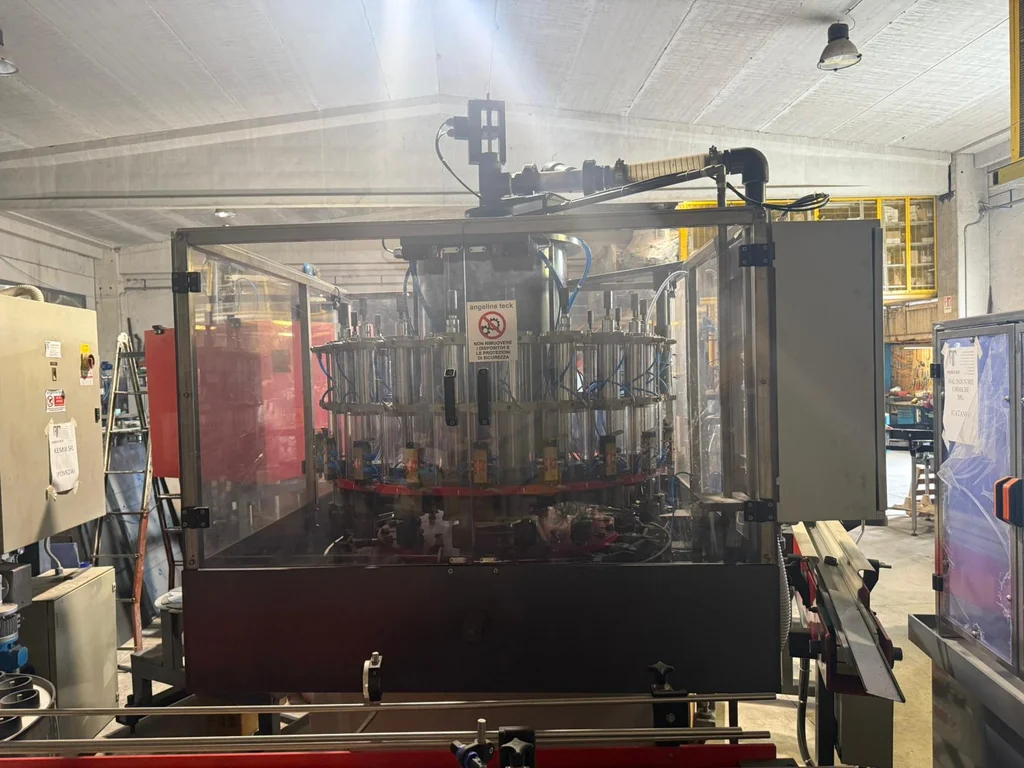

This second-hand rotary monoblock combines a 24-head volumetric piston filler with an 8-head pick-and-place spindle capper, engineered for PET and HDPE bottles up to 1 L. Designed for industrial packaging environments, it is a robust component for a used bottling line handling non-pressurized products such as detergents and liquid soap. The machine features a painted iron frame, stainless steel panels, and a fully enclosed protective hood with safety devices, offering reliable performance in high-throughput operations. CE marking and complete documentation support integration within beverage production and home & personal care lines where non-isobaric, non-aseptic filling is required.

Technical Specifications & Performance Data

- Configuration: Rotary filler–capper monoblock (24/8)

- Container materials: PET, HDPE

- Product types: Liquid detergents, liquid soap (suitable for non-carbonated, non-aseptic applications)

- Filling technology: Volumetric piston filling

- No. of filling valves: 24

- Nozzle type: Mobile nozzles

- Max fill volume: up to 1 L

- Capper: 8-head pick-and-place pneumatic spindle capper

- Cap type: Plastic screw caps (one cap size currently tooled)

- Machine rotation: Clockwise

- Nominal speed: up to 5,000 bottles/hour (depending on product, bottle, and closure)

- Isobaric: No (non-pressurized filling)

- Aseptic: No

- Integrated rinser: Not included

Filling Section

- Bottle infeed screw

- Central product tank with magnetic float switches

- 24 pneumatic cylinders, upper plates, lower plates

- Internal plates with stainless-steel/Viton sealing

- Opening/closing valves per station

Capping Section

- 8 pneumatic capping heads with spindle screwing system

- Pick-and-place cap transfer

- Vibratory cap bowl (one cap size)

- Cap cup and cap chute (one cap size)

- Automatic cap elevator

Mechanical & Structural

- Frame: Painted iron

- External panels: Stainless steel

- Protective hood: Enclosed with doors and safety devices

Advanced Automation & Control Systems

- Pneumatic control panel for filler and capper actuation

- Electrical panel with CE-compliant components

- Wiring diagram included for streamlined commissioning

- Magnetic level control in product tank for stable filling

Production Line Integration Capabilities

This monoblock integrates seamlessly into second-hand used bottling line configurations for industrial packaging and beverage production of still, non-pressurized liquids. Its clockwise carousel rotation, bottle infeed screw, and cap-handling system allow straightforward connection with upstream conveyors, depalletizers, blow molding machines, and downstream labellers, inspection systems, and secondary packaging.

- Upstream compatibility: Blow molding machine, bottle unscrambler/depalletizer, conveyors

- Downstream compatibility: Labeller, inspection/quality control, packer/shrink-wrapper, palletizer

- Changeover scope: Supplied with 1 bottle format and 1 cap format; additional formats can be engineered on request

Machine Condition & Maintenance History

- Condition: In storage

- Documentation: Use and maintenance manual (Italian) and wiring diagram

- Safety features present; CE marking

- Recommended: Technical inspection and format validation with customer bottles/caps before commissioning

Operational Performance & Versatility

- High repeatability through volumetric piston dosing for viscous and semi-viscous products

- Mobile nozzles support controlled filling and clean operation

- Pneumatic spindle capping ensures consistent torque for plastic screw caps

- Suitable for various bottle geometries in PET/HDPE within the 1 L range

- Optimized for non-isobaric, non-aseptic operations

Installation Requirements & Site Preparation

- Utilities: Electrical power per CE electrical panel specifications; compressed air for pneumatic systems

- Facility: Level flooring, sufficient access for handling and enclosure opening

- Validation: Provide representative bottles, caps, and product for setup and format verification

- Integration: Interface to existing conveyors and line control to be aligned during installation

Safety Standards & Compliance Certification

- CE marking and CE-compliant electrical panel

- Protective hood with doors and safety devices

- Machine designed for safe industrial operation within applicable EU Machinery, Low Voltage, and EMC requirements