Description

Used Complete PET Line for Water 3000 bph

1. 6 x BM500 Blow Mold system with 2 x 25 H.P. Commercial Air Compressors mounted on 1 x 240 gallon / 250 p.s.i pressure tank. 6 x pre-heaters, 6 x Blow molders, capacity up to 3000 bottles per hour. Complete with top-of-the-line air preparation and air pressure units for a consistent, reliable and oil-less air supply.

2. Ozone system BWOZ27 Deluxe ozone disinfection system

Capacity up to 190 L water per minute.

Utilizes 100-gallon stainless steel tank for ozone contact time.

Complete with an oxygen concentrator, ozone generator, Visual inspection contact tube, stainless steel pump, venturi injector, central electric controls and mounted on stainless steel frame.

Used Complete PET Spec.

3. BR3000, bottle insert, capacity up to 3000 bottles per hour, automatic rinsing and position of bottles insuring clean bottles.

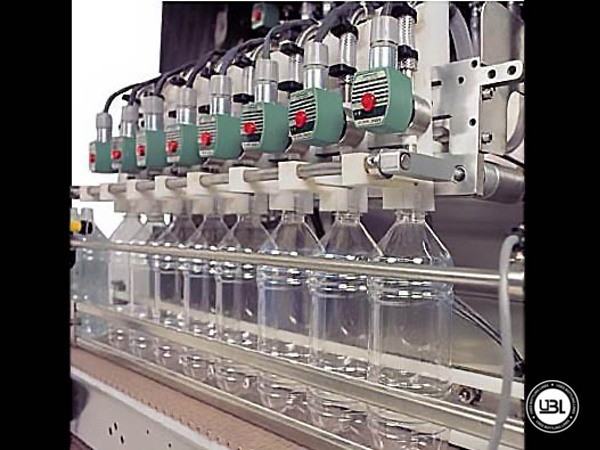

4. BF3000 bottle filler, capacity up to 3000 bottles per hour Accurately and automatically filling easily adjustable for 335 ml to 3.8 L bottles.

5. Capper/Labeller, capacity up to 3000 bottles per hour. Automatic capping – attaching outlet portion of the conveyer, spring and tightening up to 50 sport or flat top screw-on 28 mm per minute.b. Automatic labelling, accurately applying pressure sensitive labels (up to 9.5 cm wide and 22.7 cm long) to bottles after being filled and capped.

6. DC3000 Date Coding system, Ink jet, dot matrix spray system to apply batch code or date code to side of bottles.

7. 48″ Rotary feed table, to automatically feed empty bottles into main spectra Pak3000 system

8. 24 foot Automatic Main conveyor system for Spectra pack system(Included in BF3000)

9. 12″ x 10′ Accumulation Conveyer, accumulate rinsed, filled, labeled, capped and bottles for packing.

10. Installation Kit – to install the plant

11. Assorted Spare parts for one year period

12. 40 GPM U.V. System, to work in conjunction with Katadyn filter for the purpose of treating feed water for bacterial contamination.