Description

Used complete isobaric Krones filling line up to 20000 bph

Introduction: Overview and Technical Specifications

Initially, the used isobaric Krones filling line, with a capacity of 20,000 bottles per hour, offers efficient bottling solutions. Designed in 2014, it remarkably has accumulated about 14,000 hours of work on the filler. This indicates its exceptional reliability and longevity.

Versatility and Bottle Options in the complete isobaric Krones filling line

Furthermore, this system handles a wide range of bottle volumes, from 0.2 to 0.75 liters. Additionally, it provides options for different types of closures, including 28 mm and 38 mm screw caps and crown corks. Consequently, this ensures flexibility in production. The variety in labeling types, such as neck, front, back (paper), or sleeve, adds further versatility.

Compatibility with Various Products

Moreover, the line is compatible with a diverse range of bottling products. These include CSD, water, juice, energy drinks, beer, sparkling wine, and spirits. As a result, this expands market potential and production opportunities for users significantly.

Components of the Filling Line

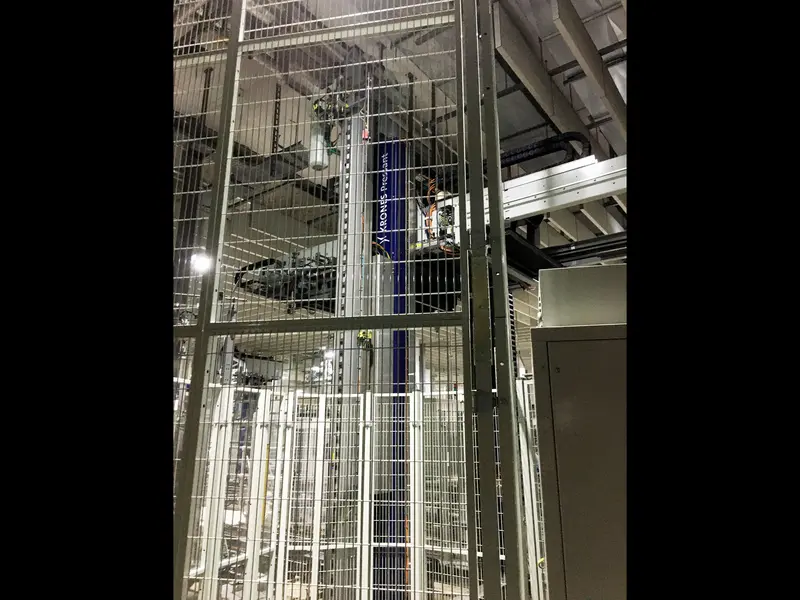

The bottling line includes several specialized components. Each contributes efficiently to the process’s overall efficiency and quality. For instance, the depalletizer for NEW GLASS, made by KRONES, ensures accurate handling of bottles. The empty bottle control system, supplied by HEUFT, guarantees that only suitable containers proceed in the process. Subsequently, efficiency is further enhanced by the unpacking and washing systems for crates and bottles, also provided by KRONES.

Filling and Capping

At the heart of the line is the KRONES MODULFILL HES (VP VI) 2.520-70-113 filler. It’s designed for precision and consistency in the filling process. Complementing this are three capping systems for aluminum screw caps and crown corks. The bottle drying system then ensures readiness for immediate labeling.

Labeling and Packaging

The plug-and-play labeling system, along with the sleever and heating tunnel, provide impeccable label application. Equally important, the VARIOPAC PRO WTS-4 carton packaging machine and SMARTPAC C 1800 T-0684 crate packer, both from KRONES, efficiently and safely prepare products for distribution.

Quality Control and Transportation

Importantly, the line includes various KRONES control systems to ensure the highest quality of each product. Finally, the precision-managed bottle and pallet transportation ensures an uninterrupted and optimized workflow.

Conclusion of the complete isobaric Krones filling line

In summary, this used isobaric Krones filling line is an ideal solution for bottling. It’s ideal for those seeking efficiency, versatility, and precision in the process. Capable of handling up to 20,000 bottles per hour and compatible with various products and bottle formats, it stands out as an excellent choice. Its immediate availability and customizable configuration to meet specific needs make it an unparalleled choice in the industry.