Description

Used CIP Tetra Pak year 2010 15T/h

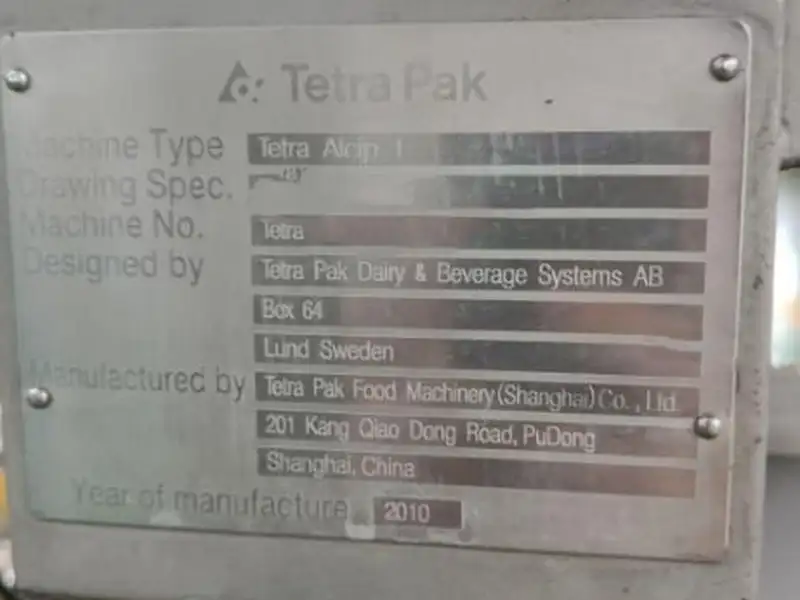

The Used CIP Tetra Pak year 2010 15T/h, model Tetra Alcip 1, performs Cleaning in Place (CIP) to automate the cleaning process in bottling and food processing plants. Consequently, this system ensures an effective sanitation cycle without requiring production line disassembly, optimizing downtime and reducing water and detergent consumption.

Tetra Pak built the Used CIP Tetra Pak year 2010 15T/h in 2010. Specifically, its 15-ton-per-hour operational capacity makes it suitable for high-productivity plants while ensuring hygiene standards that comply with food and beverage industry regulations.

Technical Features of the Used CIP Tetra Pak year 2010 15T/h

The Tetra Alcip 1 applies a controlled washing cycle to remove organic and inorganic residues from production circuits. In particular, the system integrates separate tanks for water, alkaline detergent, and acid, and it automatically regulates temperature, chemical concentration, and washing time based on plant requirements. As a result, it enhances the efficiency of cleaning operations.

Moreover, the Used CIP Tetra Pak year 2010 15T/h automates the cleaning process, reducing cross-contamination risks and improving production efficiency. Additionally, the system allows operators to configure different washing parameters, which enables adaptation to specific production needs and ensures thorough cleaning of filling lines, pipelines, and heat exchangers.

Safety and Process Control

The system includes advanced safety features, such as:

- Sensors that continuously monitor detergent concentration.

- Temperature and pressure controls throughout the cleaning cycle, ensuring optimal performance.

- Alarm systems that detect and manage sanitation process anomalies, thereby preventing potential failures.

As a result, these features ensure this Used CIP operates reliably, minimizing operational errors and optimizing water and chemical consumption. Furthermore, the system’s automated monitoring enhances safety while reducing maintenance requirements.

Operational Advantages

Using this Used CIP Tetra Pak enhances plant productivity in multiple ways. First and foremost, it reduces downtime: the continuous washing system completes fast cleaning cycles without requiring component disassembly. Moreover, it optimizes resource usage: the automatic detergent dosing system prevents chemical waste. Additionally, it ensures regulatory compliance: the system meets high hygiene standards and complies with industry regulations.

At the same time, the automated nature of this system helps manufacturers streamline their cleaning procedures. Consequently, businesses benefit from both improved production continuity and reduced operational costs. Likewise, the ability to customize cleaning parameters provides greater control over sanitization processes.

Conclusion

In summary, this Used CIP Tetra Pak provides an efficient and reliable solution for sanitizing bottling and food production plants. Since its design prioritizes automation, this system minimizes manual intervention while maximizing operational efficiency. Furthermore, its advanced safety features ensure maximum hygiene and productivity in the beverage and liquid food industry. Ultimately, adopting this system allows companies to maintain high sanitation standards while improving overall process efficiency.