Machine type

Manufacturer

Model

Year

Notes

Machine type

Depalletizer

Manufacturer

CFT

Year

2017

Notes

For empty cans

Machine type

Inspector

Manufacturer

Heuft

Year

2017

Notes

For empty cans

Machine type

Conveyors

Manufacturer

CFT

Year

2017

Machine type

Rinsing Machine

Manufacturer

CFT

Year

2017

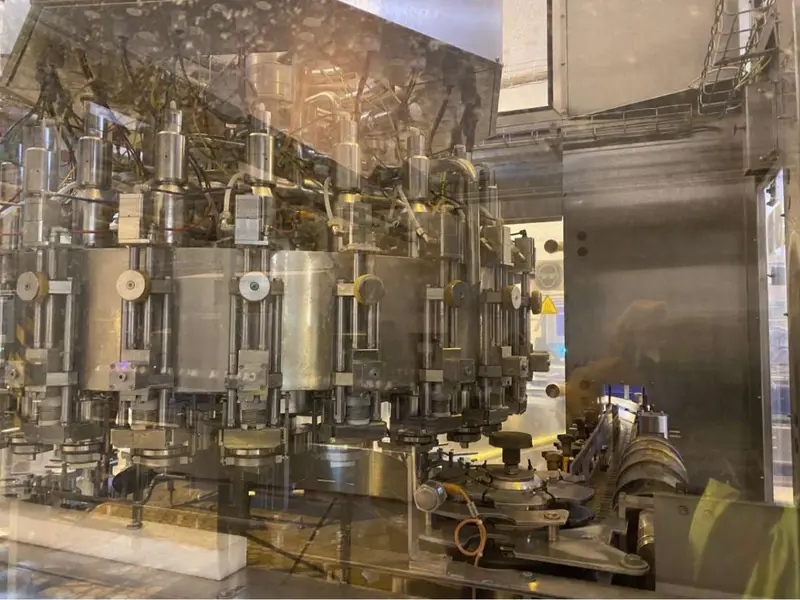

Machine type

Filling Monoblock

Manufacturer

CFT

Model

12/4

Year

2017

Machine type

Inspector

Manufacturer

Heuft

Year

2017

Notes

For full cans

Machine type

Defective can rejection system

Manufacturer

Heuft

Year

2017

Machine type

Shrink Wrapper

Manufacturer

SMI

Year

2017

Machine type

Mixer

Manufacturer

CFT

Year

2017

Machine type

Printer

Manufacturer

VIDEOJET

Year

2017