Description

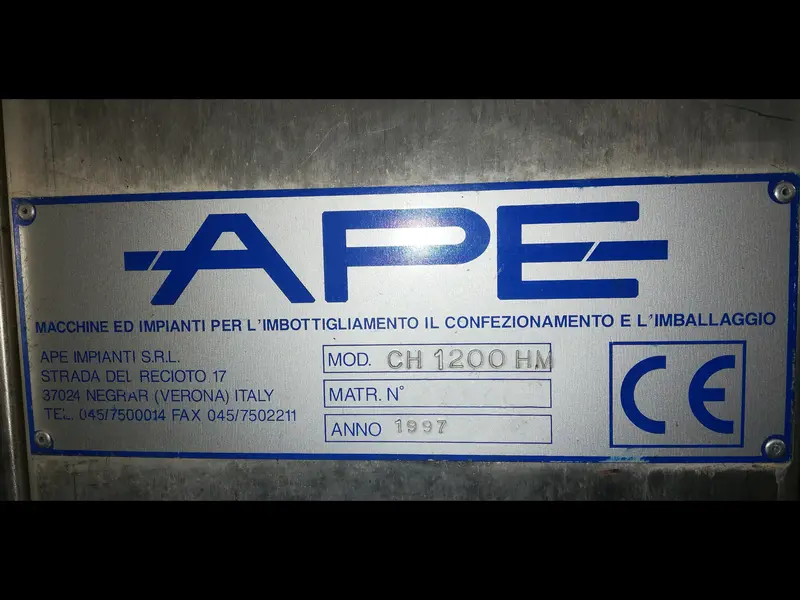

Used APE Case Sealer up to 1200 Cartons/Hour

Reliability and Efficiency

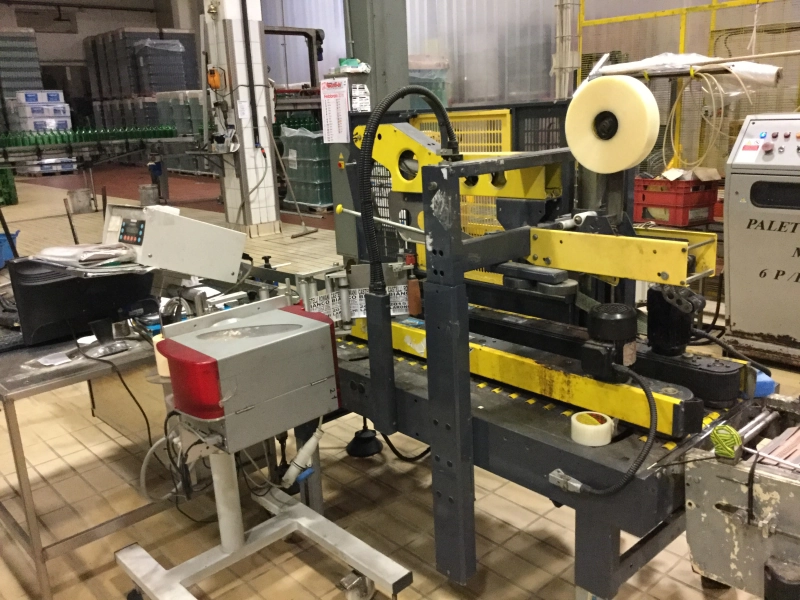

The used APE Case Sealer stands as a cornerstone of reliability and efficiency in the bottling industry. Designed for high-speed operations, it represents the pinnacle of technological advancements. Indeed, it meets the stringent demands of industrial environments with finesse and precision.

Perfect Sealing

Constructed with meticulous attention to detail, the sealing mechanism on top, reinforced with hot glue and powered by a Nordson adhesive, ensures a perfect seal. Seamlessly integrated, the automatic insertion of the carton separator simplifies the workflow. This facilitates a smooth flow of cartons and optimizes productivity at every step.

Automated Operation

The automated sealing of the rear flap, orchestrated by a pneumatic piston, adds a layer of operational sophistication. This accelerates processes and minimizes manual interventions. Furthermore, its manual adjustability allows for adaptation to a diverse range of carton sizes, offering unprecedented adaptability to evolving production requirements.

Safety Features of the APE Case Sealer

Safety remains of utmost importance, with side guards carefully constructed to minimize risks and protect operators, thus promoting a safe working environment. Entirely made of stainless steel, the used APE Case Sealer not only offers durability but is also corrosion-resistant. This ensures longevity under demanding operational conditions.

Sustained Performance

This machinery continues to operate at peak performance, achieving an impressive production rate of approximately 1200 cartons per hour. This sustained performance underscores its reliability and lasting relevance in the competitive landscape of industrial bottling.

Conclusion of the APE Case Sealer

In summary, the used APE Case Sealer up to 1200 cartons/hour embodies excellence by combining cutting-edge technology with unwavering reliability to deliver unparalleled results in bottling operations. Its robust construction, advanced features, and consistent performance make it the preferred choice for businesses seeking optimal efficiency and productivity in their bottling processes.