Description

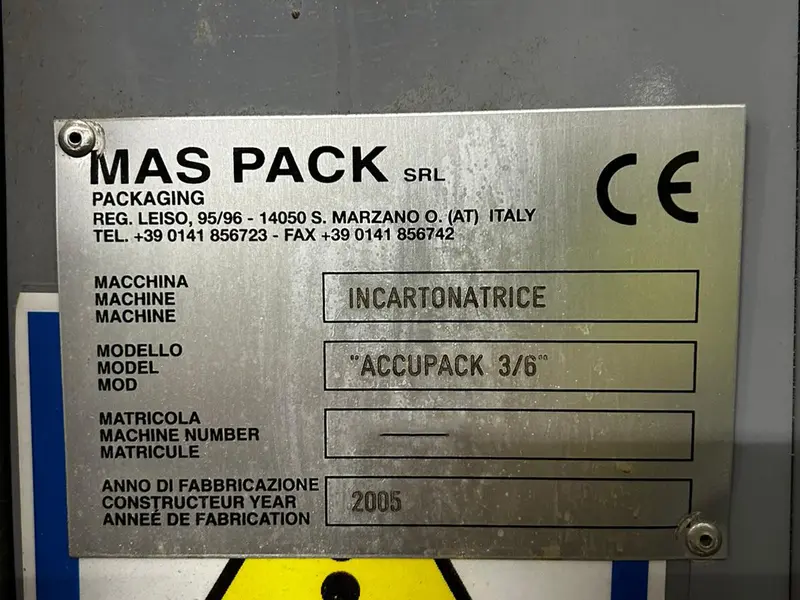

Used Case Packer MAS PACK Accupack 3/6 year 2005

The Used Case Packer MAS PACK Accupack 3/6 year 2005 packs bottles into cases with precision and efficiency. Moreover, MAS PACK manufactured this model in 2005 to meet the needs of high-capacity bottling lines. Consequently, it delivers reliability and flexibility, making it an excellent choice for companies that prioritize speed and accuracy.

Technical Specifications and Operational Capacity

The Case Packer MAS PACK Accupack 3/6 processes up to 12,000 bottles per hour. Furthermore, it handles glass containers efficiently and accommodates formats of 0.375 liters, 0.75 liters, and 1.5 liters. In addition, the machine’s fixed head and left-side operator setup improve access and streamline operations, enabling smooth packaging processes.

Working Configurations of the Case Packer MAS PACK

This case packer supports two main configurations. Specifically, it processes four cases of six bottles each or two cases of twelve bottles. Therefore, these options allow operators to adapt the machine to different production requirements and optimize performance without sacrificing speed. Additionally, the flexibility in configurations ensures it meets a wide range of operational demands.

Materials and Versatility

MAS PACK designed the Accupack 3/6 to maintain consistent performance over time. For example, the system stabilizes glass bottles during the packing process and minimizes the risk of damage. Likewise, its ability to switch between multiple formats without complex adjustments increases its versatility and value for production lines. Consequently, it remains a practical choice for industries with varied production needs.

Ideal Applications

The machine supports companies that package standard glass bottle formats, such as those in the wine, spirits, and premium water industries. Moreover, its high production speed enables efficient operation on bottling lines with demanding throughput requirements. Notably, by ensuring careful handling of glass containers, it maintains the quality of packaged products. Similarly, the machine’s adaptability helps businesses maximize output and minimize errors.

Technical Conclusions of the Case Packer MAS PACK

The Used Case Packer MAS PACK Accupack 3/6 year 2005 enhances productivity and flexibility for glass bottle packaging. Additionally, it reaches speeds of 12,000 bottles per hour and works with diverse case configurations to meet varying production goals. Furthermore, its compact design and operator-friendly layout save space while maintaining high performance. Consequently, it serves as a reliable asset for modern bottling operations.