Description

Used case packer APE INCA 2000 year 2004

The APE Impianti INCA 2000 bottling machine optimizes filling processes in the bottling sector. It provides high performance and adapts to various production needs. APE Impianti manufactured the INCA 2000 model in 2004 with a focus on robustness and reliability. Its full stainless steel construction also ensures corrosion resistance, delivering long-lasting durability in high-demand environments.

Capacity and Operating Speed of the Case Packer APE INCA 2000

The INCA 2000 operates at a rate of 6000 bottles per hour. It maintains high-speed standards without compromising filling accuracy. This capacity meets the demands of intensive bottling lines, improving production flow. Additionally, it minimizes machine downtime. Companies needing high daily volumes gain a particular advantage from this speed.

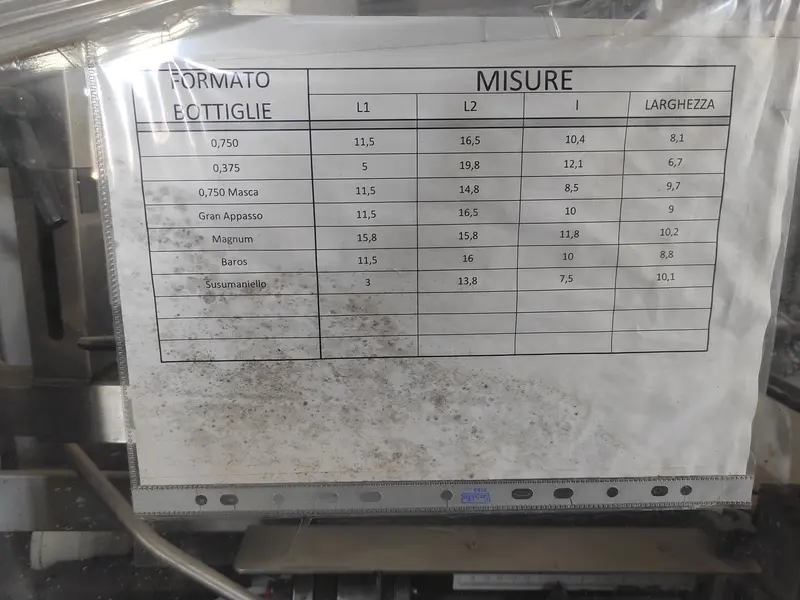

Container Specifications

The APE Impianti INCA 2000 bottling machine works with glass containers. This compatibility ensures both stability and durability during the bottling process. It supports 0.75- and 0.375-liter bottles, adding versatility for different product lines. Its precision meets the beverage sector’s standards, where filling uniformity and container integrity are crucial.

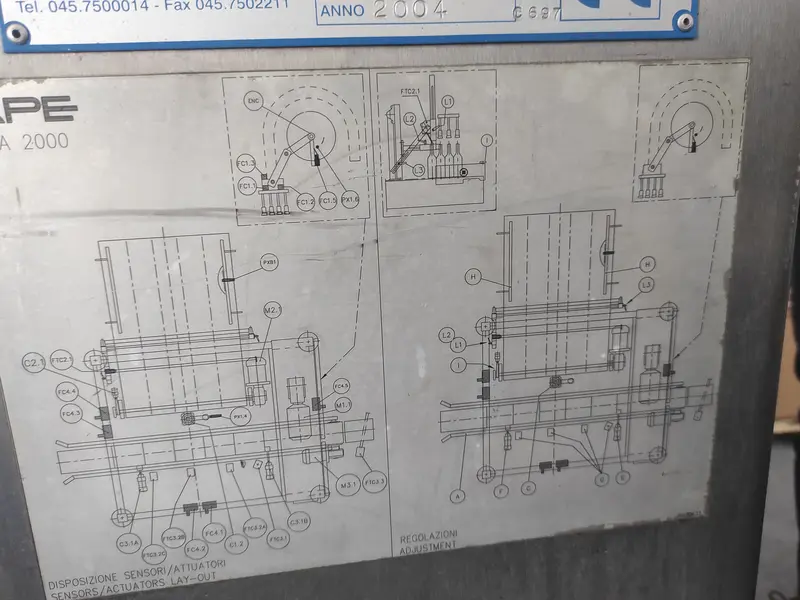

Head Configuration and Structure

The machine uses 12 heads, which provide stability and consistency. The heads are arranged in two sets of 6 or one set of 12. This flexible configuration optimizes flow based on specific production needs. The modular structure also allows easy maintenance and replacement of heads without reducing productivity.

Operational Orientation

The operator side is located on the left, making control straightforward during monitoring and adjustment. This layout enables easy access to key components during routine operations and maintenance. The left-side position reduces intervention times and increases operator safety.

Construction Material and Durability

The INCA 2000’s stainless steel structure provides resistance to corrosion and offers structural stability. This feature also ensures hygienic safety, crucial in the food industry. Stainless steel minimizes the need for extraordinary interventions, which adds maintenance value and longevity. This choice of material meets the mechanical and chemical resistance required for intensive production.

Conclusion of the Case Packer APE INCA 2000

The APE Impianti INCA 2000 bottling machine offers both efficiency and durability. It provides a speed of 6000 bottles per hour, compatibility with different glass formats, and a modular head structure. These features meet the challenges of modern bottling lines. Its stainless steel construction and ergonomic layout deliver efficiency, precision, and durability. For companies focused on quality and productivity, this machine is a valuable investment.