Description

Used Case Erector KRONES up to 2000 boxes/hour

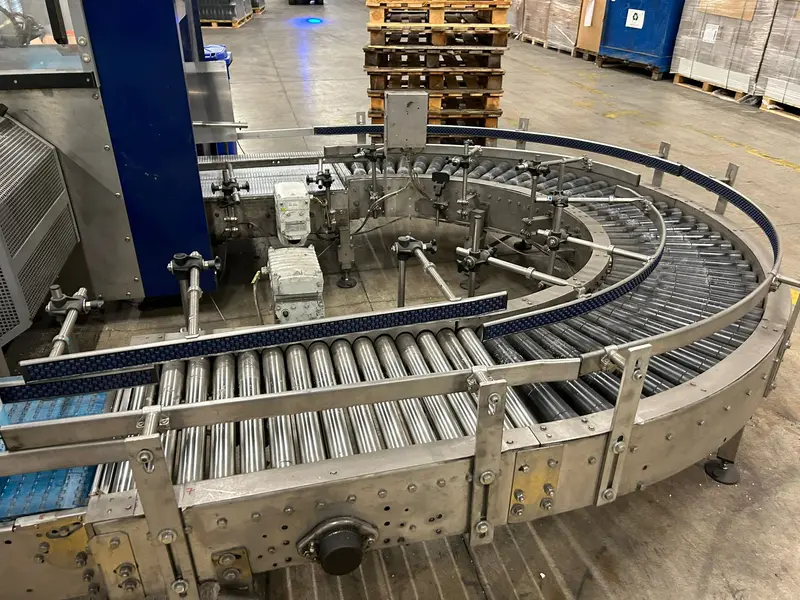

The Used Case Erector KRONES up to 2000 boxes/hour offers advanced packaging solutions for industrial applications. Moreover, Krones manufactured this machine in 2013 to deliver high productivity and precision for bottling operations. This integrated in the Case Erector KRONES system efficiently forms cardboard boxes using hot glue, ensuring reliable and uniform seals. Additionally, it enhances the efficiency of packaging lines while reducing downtime.

Technical features of the Case Erector KRONES

This model processes up to 2000 boxes per hour, maintaining high levels of efficiency. Furthermore, the hot glue closure system secures stable and consistent seals, making it suitable for various packaging requirements. Integrated safety features actively reduce operational risks while ensuring compliance with industrial standards. For this reason, the Case Erector KRONES remains a popular choice in high-demand environments.

Electrical data and compatibility

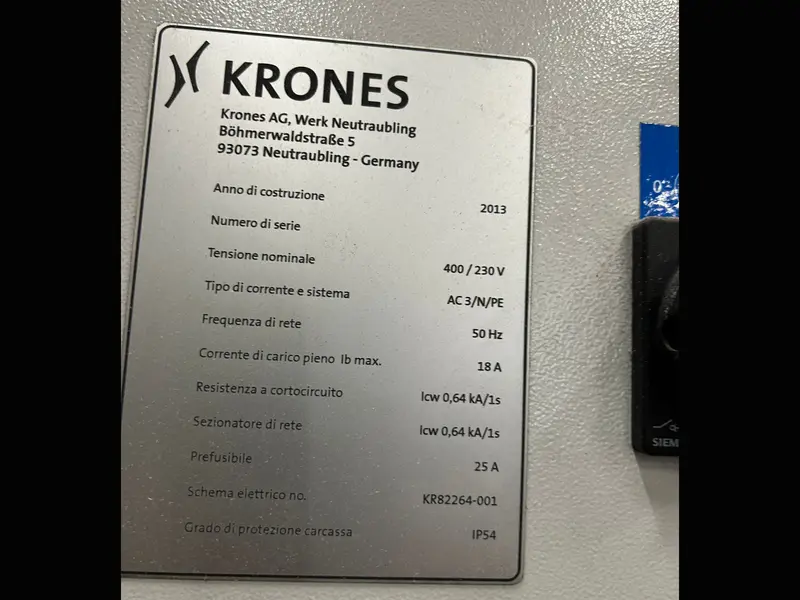

The Case Erector KRONES runs on a three-phase power supply at 400/230 volts with a frequency of 50 Hz, ensuring optimal current usage. Consequently, its design enables seamless integration into existing facilities, avoiding the need for complex modifications. In addition, it minimizes energy consumption, which contributes to its operational cost-effectiveness.

Applications and operational advantages

This machine delivers exceptional reliability in high-intensity production settings. Specifically, it handles up to 2000 boxes per hour, meeting the demands of high-speed bottling lines. Furthermore, the hot glue sealing system guarantees effective closures, preserving product integrity during transportation and storage. As a result, manufacturers can ensure product quality even under challenging conditions.

Compliance with safety standards

Krones designed the Case Erector KRONES with integrated safety devices to protect operators during every stage of use. Notably, its safety features comply with current regulations, ensuring a secure and legally compliant working environment. Consequently, operators can focus on maintaining productivity without compromising safety.

Conclusion of the Case Erector KRONES

A Used Case Erector KRONES up to 2000 boxes/hour delivers high performance at a lower cost. Moreover, its durable construction and comprehensive technical documentation support long-term operational use, even in intensive production scenarios. In particular, the machine’s reliability and affordability make it a practical choice for businesses looking to enhance efficiency. Therefore, investing in the Case Erector KRONES helps companies achieve optimal results without exceeding budget constraints.