Description

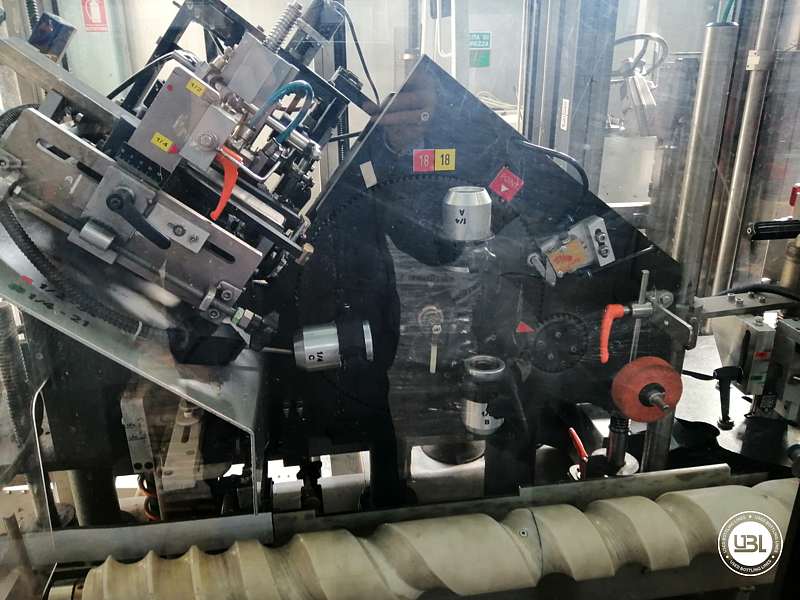

Used Capsuling Machine Robino & Galandrino ZENITH 2/12 OTTICO

Monoblock for dispensing and crimping of capsules composed of a rigid base made of fully electro-welded steel, coated in stainless steel.

Machine complete with:

– Automatic capsule dispenser with single bell or rotating multi-bells with “elliptical-co-tilting “suitable for picking up and the capsules from the storage to and placing it onto the bottle, guaranteeing precision and reliability of placement. The capsules, before expulsion into the bell, are pre-extracted by a mechanical system.

– 1 rotary carousel complete with pneumatic heads for the first closure of the sparkling wine capsule and the formation of the 4 folds.

-1 transfer star between the first and second carousel, complete with locking pliers to keep completely the bottles in place, guaranteeing the perfect smoothing of the capsule in the subsequent phase.

-1 rotary carousel complete with pneumatic heads for the final smoothing of the big capsule.

– Centralized electrical panel complete with inverter and PLC.

– Electronic bottle flow control systems in machine entry and exit with automatic stop and start in case of a lack of bottles in at the entry or bottle clogging at the exit.

– Safeguards according to CE standards. Air consumption (at 6 bar): 6 liters / sec, for all models

The machine is in excellent condition and ready for sale.