Description

Used SIDEL Bottling Line for Still Water up to 54000 Bottles per Hour

Introduction of the Used bottling Line SIDEL for still water up to 54000 bph

The used SIDEL bottling line for still water up to 54000 bottles per hour is currently built in 2014 operational and offers high performance. Specifically designed to package still water in 0.5 liter PET bottles, this line meets the needs of large scale production. Moreover, the Sidel water line reaches a production speed of 54000 bottles per hour, thereby optimizing operational efficiency for high quality products.

Filling Technology and Bottle Specifications

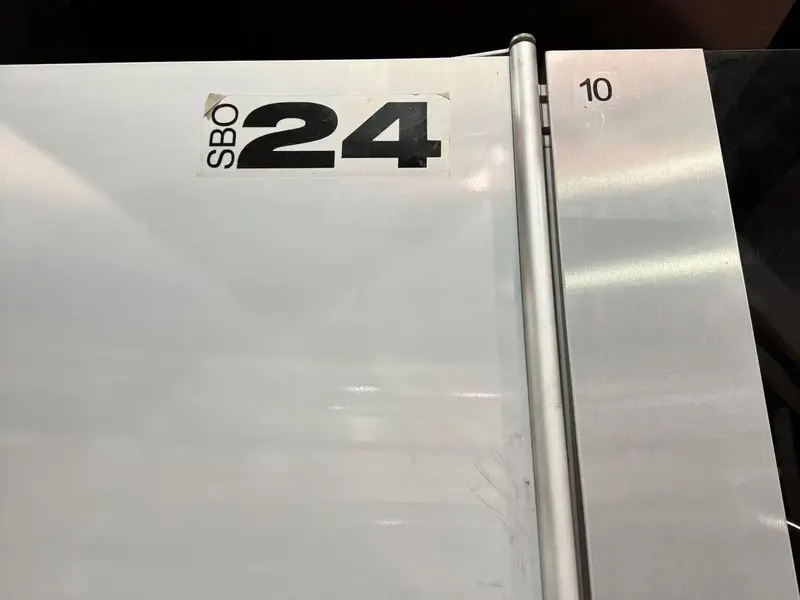

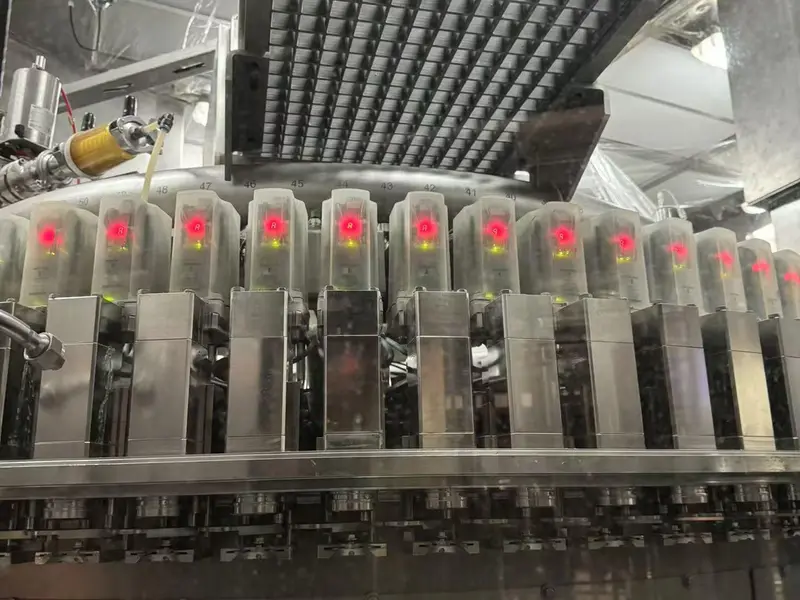

This Sidel water line employs gravity filling technology with light depression, ensuring precise and consistent dosing of the product. Additionally, the bottle neck type is the standard 30. or 25, which is common in the bottling industry. Having operated for a total of 10000 hours, the line has demonstrated reliability and robustness over time. With 24 blowing cavities and 84 filling nozzles, it significantly increases production capacity.

Main Components of the Line

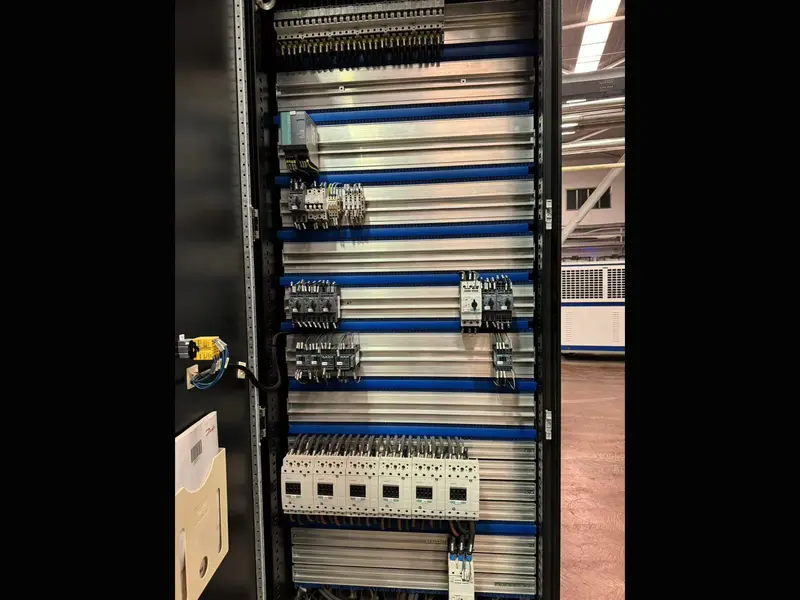

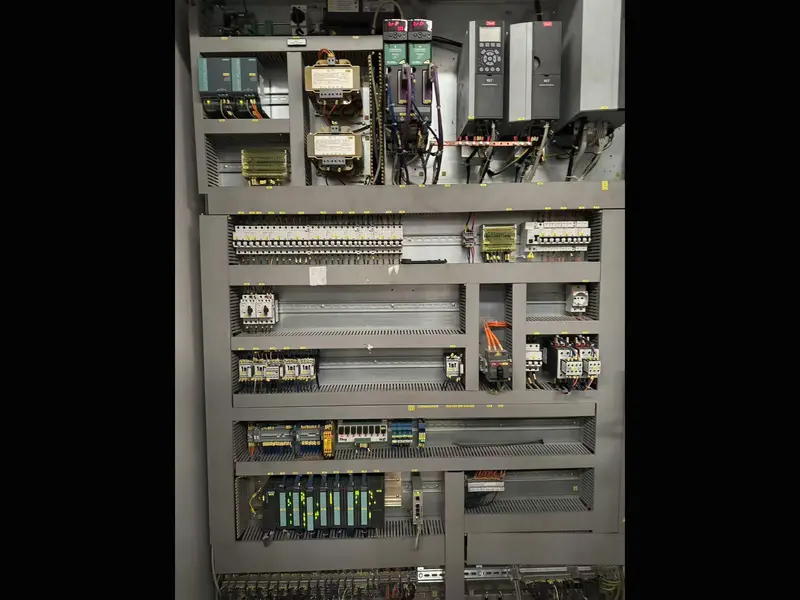

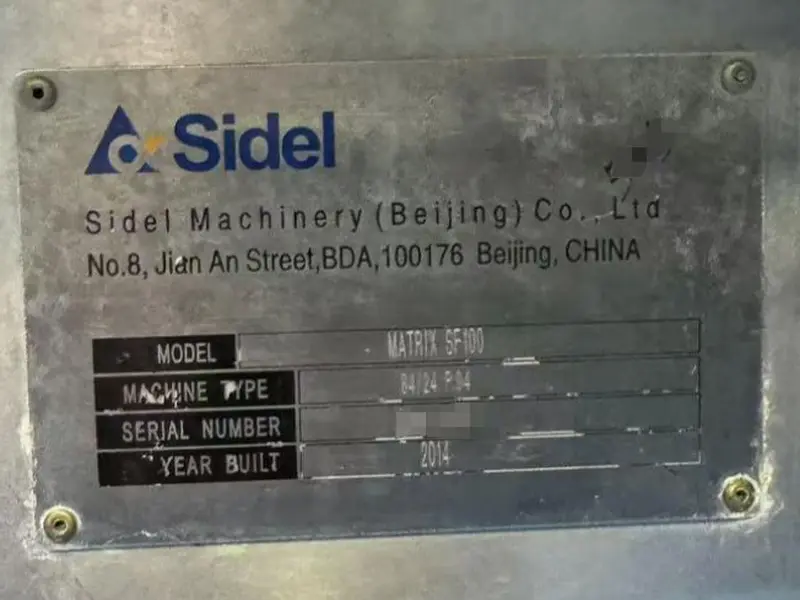

At the core is the 2014 SIDEL Combi SBO24 Matrix system, which combines blowing, filling, and capping functions in a compact unit. Configured with 24 blowing cavities and 84 filling nozzles, it optimizes productivity, allowing the used SIDEL bottling line for still water up to 54000 bottles per hour to operate at full capacity.

Cleaning and Preparation Systems

Furthermore, the CIP system provided by Beijing Sanyuan of the Sidel water line ensures automated cleaning of parts in contact with the product, which is essential for maintaining hygienic standards in bottling still water. The SH Yiwei bottle dryer removes residual moisture, thus preparing the bottles for subsequent stages. Together, these components contribute to the overall efficiency of the line.

Marking and Quality Control

A DOMINO laser bottle printer allows direct marking on the bottles with clear and indelible information. Haifu inspectors control the filling level and verify correct label application, thereby ensuring the quality of the final product. Consequently, the used SIDEL bottling line for still water up to 54000 bottles per hour maintains high quality standards.

Labeling and Traceability of the Used bottling Line SIDEL for still water up to 54000 bph

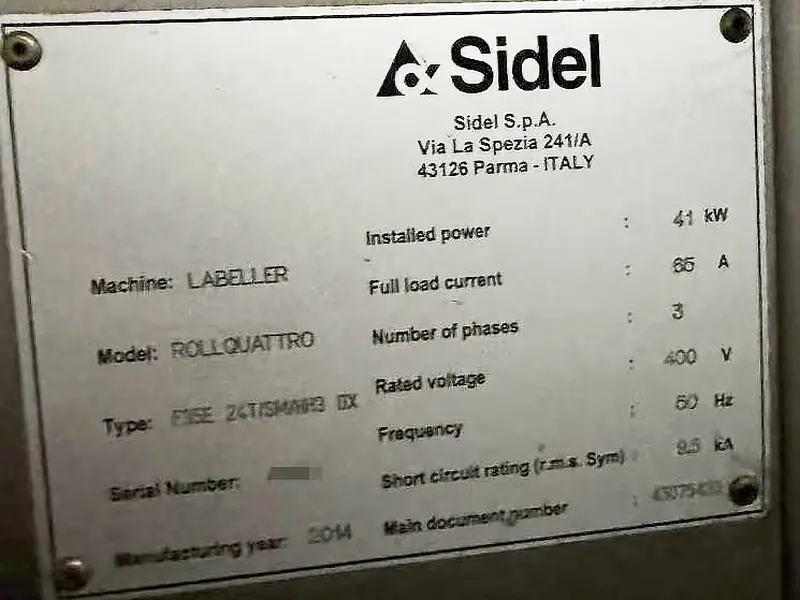

Moreover, the 2014 SIDEL ROLLQUATTRO labeling machine uses roll fed labeling technology, allowing rapid and precise label application. An additional DOMINO printer prints on cartons, providing necessary codes and information for logistics and traceability. As a result, this setup makes the Sidel water line a complete solution for the entire packaging process.

Packaging and Weighing Systems

An OCME case packer automates the packing of bottles into boxes for this Sidel water line. Additionally, the SARTORIUS scale provides accurate weight measurements, which are essential for quality control. These elements ensure that each package meets required standards, thus contributing to the efficiency of the used SIDEL bottling line for still water up to 54000 bottles per hour.

Summary of Technical Features of Sidel water line

In summary, the used SIDEL bottling line for still water up to 54000 bottles per hour offers a robust and reliable platform. With technical features like 24 blowing cavities and 84 filling nozzles, along with high quality components, it meets the needs of professionals in the bottling industry. It provides an efficient and high quality solution for producing bottled still water.

In this configuration you need to add new conveyor system new because there are not.

The line can produce up to 36,000 bph in this configuration because you have only one labeler that can produce up to 36,000, but if you want to get to 54,000 you can add another OPP rotary labeler and size the belts at the speed of 54,000 bph and then you can get it.

The Combi matrix 24/84/24 is a guarantee of reliability and precision and has only 11,000 working hours, so almost new and kept in excellent condition.

We dismantled it at the end of December / beginning of January 2025 and stored it.

No mould available because are registred.

Overall, this line stands out for its efficiency and reliability. Moreover, it integrates seamlessly into existing production setups. Additionally, the advanced features ensure consistent product quality. Therefore, investing in this line can significantly boost production capacity. Furthermore, it adheres to industry standards, ensuring compliance and safety. As a final point, the line’s operational excellence makes it a valuable asset for any bottling company.