Description

Used Bottling Line SIDEL for still water up to 12000 bph

Main features of the bottling line

The used SIDEL bottling line for still water up to 12000 bottles per hour delivers high standards of productivity and precision. Moreover, the system produces 12000 bottles per hour, making it suitable for medium high production capacities. The line processes PET containers, handling formats ranging from 0.33 L to 1.5 L.

Additionally, this line applies a volumetric filling system, ensuring accurate dosing for each bottle. It supports containers with neck types between 25 and 29 mm, thereby improving compatibility with various market standards. Furthermore, the system exclusively processes still water, maintaining a specific and dedicated production flow.

Details of the equipment in the Used Bottling Line SIDEL for still water up to 12000 bph

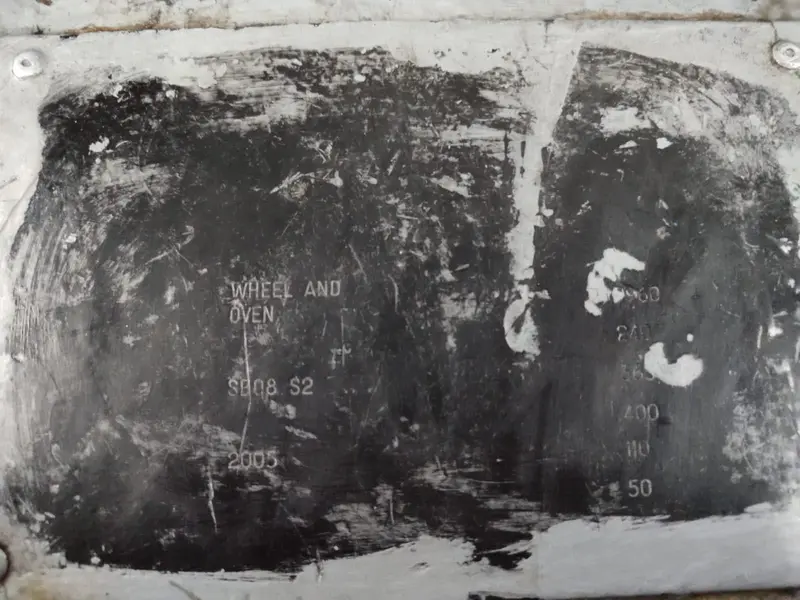

The Sidel SBO 8 blow molding machine, manufactured in 2005, forms the bottles at the core of the process. Notably, this machine transforms preforms into finished bottles using high pressure compressed air. Therefore, SIDEL technology ensures precise shaping and optimizes PET material usage, minimizing waste.

Filling Monoblock

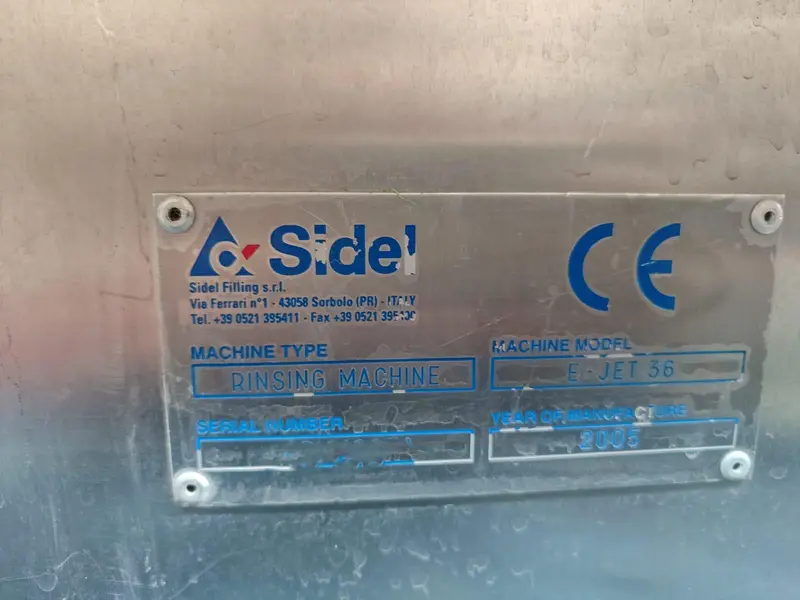

The Sidel 36 36 9 filling monoblock, also from 2005, performs rinsing, filling, and capping in a single compact unit. This design maximizes space efficiency and reduces transfer times between stages. Consequently, the volumetric filling system delivers precise dosing, which ensures the final product quality.

Labeling Machine

The PE Labellers ROLLMATIC labeling machine, from 2005, applies wrap around labels to containers. Advanced technology positions labels accurately, thus enhancing the finished product appearance. This system works perfectly for PET water bottles, meeting the line speed and quality requirements.

Shrink Wrapper

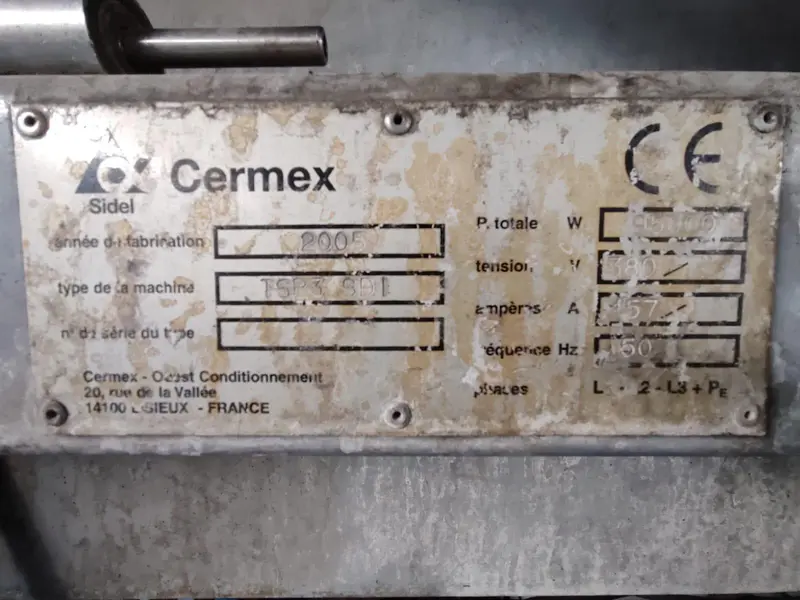

The Sidel Cermex shrink wrapper, from 2005, performs secondary packaging. Specifically, the machine uses shrink film to create compact and secure packs. As a result, this process enhances logistics and product distribution while protecting items during transport.

Conveyors in the Used Bottling Line SIDEL for still water up to 12000 bph

The line operates with a complete system of conveyors, both air and ground. These conveyors maintain a continuous and uninterrupted flow between production stages. Additionally, the conveyors minimize downtime and ensure high operational efficiency.

Technical advantages of the line

This used bottling line delivers reliability and robustness, even with its 2005 manufacturing date. Moreover, all machines ensure a long operational life and reduce maintenance costs. The system efficiently bottles still water, ensuring a specific and contamination free process.

Furthermore, SIDEL machinery integrates seamlessly with complementary components, such as the labeling machine and shrink wrapper, to maintain a uniform production flow. With a speed of 12000 bottles per hour, this line supports companies with consistent production demands.

Conclusion

The used SIDEL bottling line for still water up to 12000 bottles per hour provides a reliable and highly efficient solution for the bottling sector. Therefore, with robust machinery and an optimized configuration, it meets the needs of technicians and experts requiring a complete solution for producing PET water bottles.