Description

Used bottling line SIDEL for still water in PET bottles 25200 bph

The used bottling line SIDEL for still water in PET bottles 25200 bph provides a complete solution for bottling still water. Currently, the line remains connected to power, so buyers can test it directly. SIDEL designed the system in 2006 to handle PET bottles ranging from 350 ml to 1.5 liters. As a result, the line maintains high productivity and flexibility.

General line data

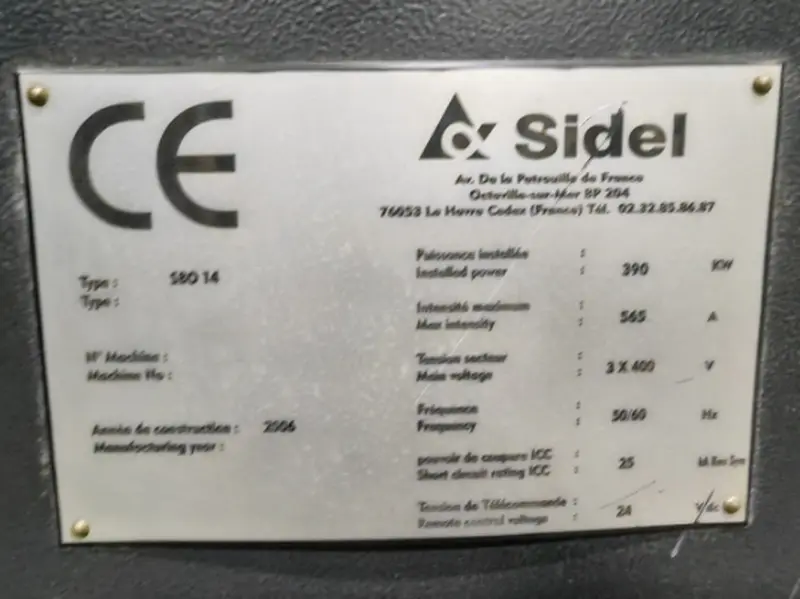

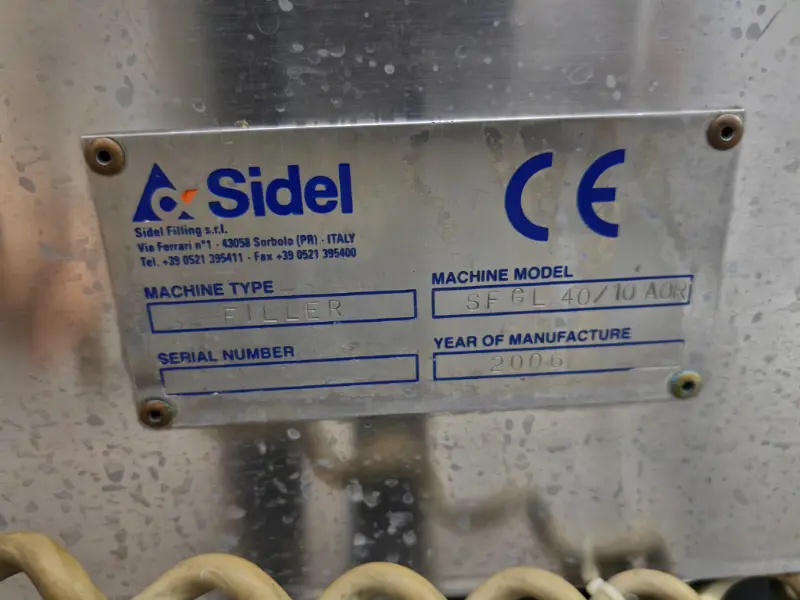

This used bottling line SIDEL for still water in PET bottles 25200 bph processes up to 25200 bottles per hour. Specifically, it uses 30/25 neck-type bottles, which match standard formats across the industry. SIDEL equipped the line with a SB014 blow molder featuring 14 cavities. Furthermore, the filling and capping monoblock includes 40 filling valves and 10 capping heads, making it suitable for still products.

Main installed machines

The line includes, among other components, an AF high-pressure compressor (model CE46A) and a Fusheng low-pressure compressor (model SA110A). In addition, a BAC cooling tower manages process temperatures effectively. The SIDEL SB014 blow molder, which includes a hopper, feeder, and dust remover, connects directly to the SIDEL SFGL40/10 filling machine. Consequently, the line maintains efficiency across all stages.

Labeling and packaging

SIDEL integrated a Rollquattro labeler that applies roll-fed wraparound labels with precision. Moreover, a shrink-wrapper creates stable multi-pack bundles using plastic film. The VANTA WSD-B350 carton packer, built in 2011, handles up to 35 cartons per minute. Likewise, a palletizer automates the end-of-line phase, thereby preparing products for shipment.

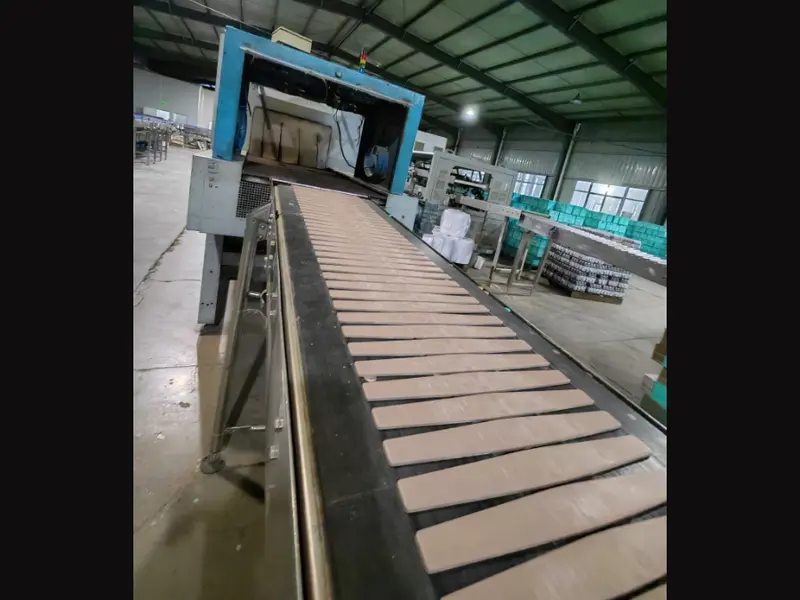

Conveying system and internal logistics

The conveying system uses SIDEL-built conveyors throughout the process. Accordingly, the line ensures uninterrupted flow from the blow molder to the palletizer. Thanks to this automation, the system reduces manual intervention and improves consistency. In contrast to fragmented setups, this configuration enhances operational control and reduces downtime.

Operating conditions and advantages

This used bottling line SIDEL for still water in PET bottles 25200 bph operates under power and remains available for on-site testing. In practice, the integration of SIDEL machines improves performance while simplifying maintenance. As such, operators can rely on uniform quality and long-term reliability.

Applications and compatibility

The line suits facilities bottling still water in PET containers of multiple sizes. Importantly, its modular design enables quick format changes with minimal disruption. Because of this, companies can adapt to different production requirements. Notably, the system supports both small batches and high-volume output.

Technical conclusion

The used bottling line SIDEL for still water in PET bottles 25200 bph delivers a robust, efficient, and scalable bottling solution. Undoubtedly, SIDEL’s engineering ensures durability and optimal integration. For this reason, companies seeking a cost-effective way to expand production will find this line technically sound. Ultimately, it represents a valuable opportunity for those who need to scale operations without investing in new machinery.