Description

Used Bottling Line SIDEL for still water 14400 bph

The Used Bottling Line SIDEL for still water 14400 bph delivers a complete solution for bottling still water in PET containers. The line handles 0.50-liter, 0.75-liter, and 1.5-liter bottles, offering flexibility for beverage producers. The Used Bottling Line SIDEL operates at a nominal capacity of 14,400 bottles per hour, making it ideal for medium to high-volume production environments. As a result, technical teams can integrate this system into existing plants or install it as a standalone unit to achieve consistent, high-throughput output.

Core Unit of the Used Bottling Line SIDEL: COMBIBLOCK SIDEL 8-40-8

In this Used Bottling Line SIDEL we find the COMBIBLOCK SIDEL 8-40-8, manufactured in 2006, performs blow molding, filling, and capping in a single integrated unit. First, the SBO 8 blow molder forms PET bottles from preforms using 8 cavities, supporting all three bottle formats.

Next, the COMBI UNIVERSAL EUROPA WM filler uses 40 volumetric filling valves to deliver precise product dosing and minimize waste during production. Because the system uses volumetric filling, it provides consistent accuracy, especially for low-viscosity products such as still water.

Then, the capping unit applies caps using 8 heads on bottles with 25 to 30 mm neck diameters. In addition, operators can perform quick format changes and maintain compatibility with industry-standard closures.

Secondary Packaging: CERMEX Tray Packer in the Used Bottling Line SIDEL

Following the filling and capping process, the CERMEX tray packer, installed in 2007, arranges and packs bottles in pre-defined tray configurations. It forms the following bundles:

-

1.5-liter bottles in a 2×3 configuration

-

0.75-liter bottles in a 4×3 configuration

-

0.50-liter bottles in a 4×3 configuration

Consequently, the unit ensures consistent secondary packaging and supports downstream palletizing operations. Moreover, the machine maintains uniformity across batches and eliminates manual packing variability. Therefore, it significantly increases line efficiency.

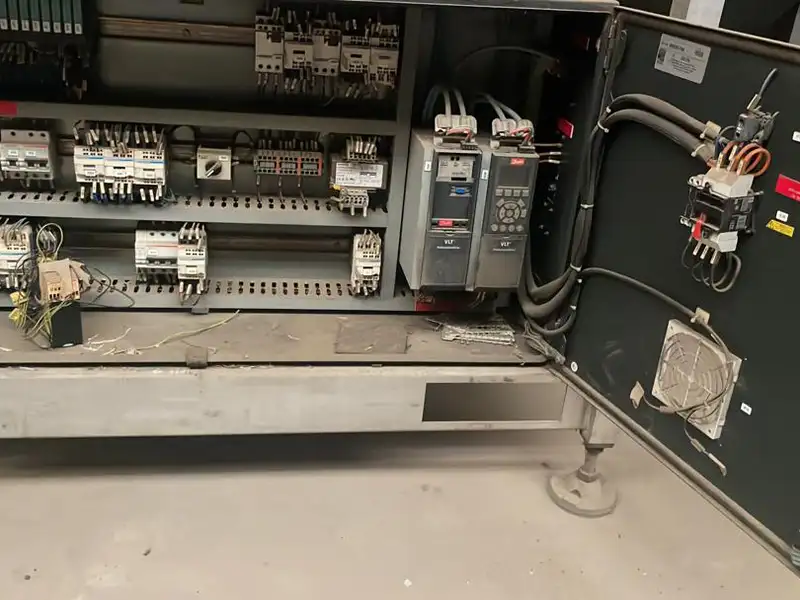

Compressed Air Supply: High and Low-Pressure Compressors

The line includes two compressors that support the blow molding and cooling systems. Specifically, the SIAD TEMPO 2 high-pressure compressor delivers 1,500 m³/h and supplies compressed air to the SBO 8 blow molder.

In contrast, the BAC F-100 low-pressure compressor, manufactured by Baltimore Aircoil in 2006, supports the evaporative cooling process. Together, these compressors maintain optimal conditions for both product quality and mechanical performance.

Bottle Conveying System: SIDEL Conveyors

The SIDEL conveyors, installed in 2006, transfer bottles between stations smoothly and efficiently. As a result, the conveyors synchronize movements across modules and prevent accumulation or blockages. Furthermore, they maintain a steady flow, which optimizes line performance and minimizes downtime. Notably, the system is fully compatible with the rest of the Used Complete Bottling Line SIDEL and requires minimal manual intervention.

Mould Availability and Equipment Condition

As for the Used Complete Bottling Line SIDEL, operators can immediately resume production using the available molds for 0.50-liter, 0.75-liter, and 1.5-liter bottles. Therefore, teams can reduce setup time and avoid sourcing delays.

Technicians last operated and overhauled the SBO 8 blow molder in 2013. Since then, the machine has remained out of production but can be recommissioned with standard preventive maintenance.

Technical Summary of the Used Complete Bottling Line SIDEL

The Used Bottling Line SIDEL for still water 14400 bph offers an integrated, high-efficiency solution for bottling still water in PET. Each component, from blow molder to conveyors, performs a specific function to ensure smooth and accurate operation. Additionally, the Used Bottling Line SIDEL includes essential auxiliary systems such as compressors and packaging automation.

While some equipment may require inspection before startup, the overall system presents a fully functional solution for industrial use. Ultimately, the combination of reliable components, available molds, and modular design makes this line a strategic asset.