Description

Used Bottling Line for still wine 2000 bph

The Used Bottling Line for still wine 2000 bph processes still wine in glass bottles and handles formats of 0.375 L, 0.75 L, and 1.5 L. The line delivers a performance of 2000 bottles per hour and operates entirely in a clockwise direction. Each machine is designed to ensure precision, compatibility, and reliability when handling still wine in glass containers. Moreover, the configuration supports a continuous and linear bottling process with minimal manual intervention.

Microfiltration and feeding unit

The process begins with a mono screw pump equipped with a microfiltration system, manufactured in 1999. This pump directly feeds the filler and maintains consistent product flow. Specifically, the filtration unit includes three housings, each containing three filter cartridges, in addition to all required connectors. As a result, this module guarantees the microbiological safety of the wine before it enters the filling phase.

Rinsing machine SBR 1R. 4. 12. 132

Next, the line passes through an SBR rinsing machine, model 1R. 4. 12. 132, also built in 1999. It features 12 grippers with fixed nozzles, and performs bottle rinsing using recirculated water. In particular, this unit supports Champagnotta (90 mm diameter), Borgognotta (80 mm diamater), and Bordolese (72 mm diameter) bottle diameters. Therefore, it ensures that every bottle reaches the filling station free of particulate and microbiological residue.

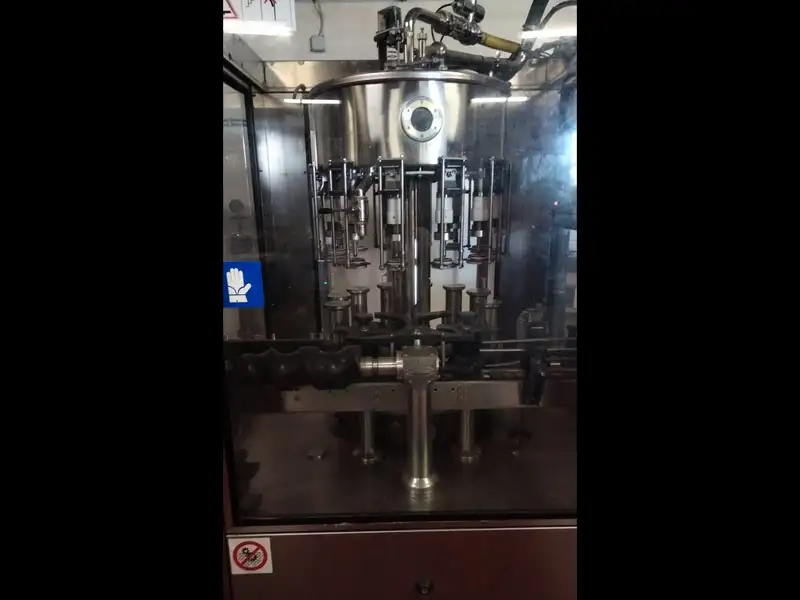

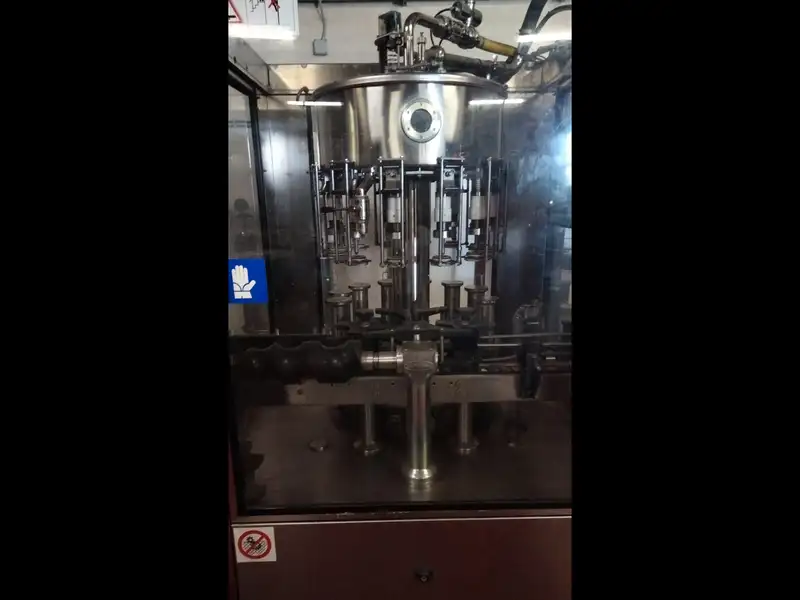

Gravity filler Bertolaso Olimpia 12

After rinsing, the bottles move to a Bertolaso Olimpia 12 filler, a gravity-based unit with 12 filling nozzles built in 1999. This machine operates with slight vacuum assistance, ensuring gentle product handling. Notably, it accommodates multiple formats, including half bottle (63 mm diameter), Bordolese, Borgognotta, Champagnotta, and Magnum (110.5 mm diameter). Consequently, the machine offers flexibility in batch production. In short, the filler guarantees accurate volume control and clean filling cycles tailored for still wine.

Capping units for crown and straight corks in the Used Bottling Line for still wine

The Used Bottling Line for still wine 2000 bph features two separate capping modules. First, the Bertolaso Alfa 110 applies 29 mm crown caps using a single-head system. Operators can adjust the height manually, and the machine works without vacuum pre-treatment. For example, it seals Champagnotta and Magnum spumante bottles efficiently.

Second, the Bertolaso S. Gloria 500 R/S handles 24 mm straight corks with gas injection and one capping head. Unlike the first unit, it does not use vacuum. Furthermore, it handles formats from 63 mm to 110.5 mm diameter, maintaining high sealing reliability. Altogether, these two capping stations allow the line to manage various closure types for still wine applications.

Bottle washer and drying system in the Used Bottling Line for still wine

Following capping, the bottles pass through a Cames washing and drying system, built in 1999. This machine integrates two washing heads and dries bottles with air blades. Importantly, it supports Champagnotta, Borgognotta, and Bordolese formats. Thus, it prepares the surface for labeling by ensuring moisture-free glass, which is essential for adhesive label performance.

Self-adhesive labeling and end-of-line handling

The labeling system uses a Cavagnino e Gatti CG80/4/2XPS unit from 2012. With two active stations and a third optionally installable, it can apply up to 2500 labels per hour. Moreover, the machine provides label centering and format versatility, ranging from 0.375 L to 1.5 L. In other words, it supports both small- and large-format production runs.

Finally, the Used Bottling Line for still wine 2000 bph includes Bertolaso conveyors (1999) and a rotary accumulation table at the outfeed. Together, these components streamline bottle flow and simplify downstream packaging operations. Overall, the line offers a technically complete, scalable solution for still wine bottling in glass.