Description

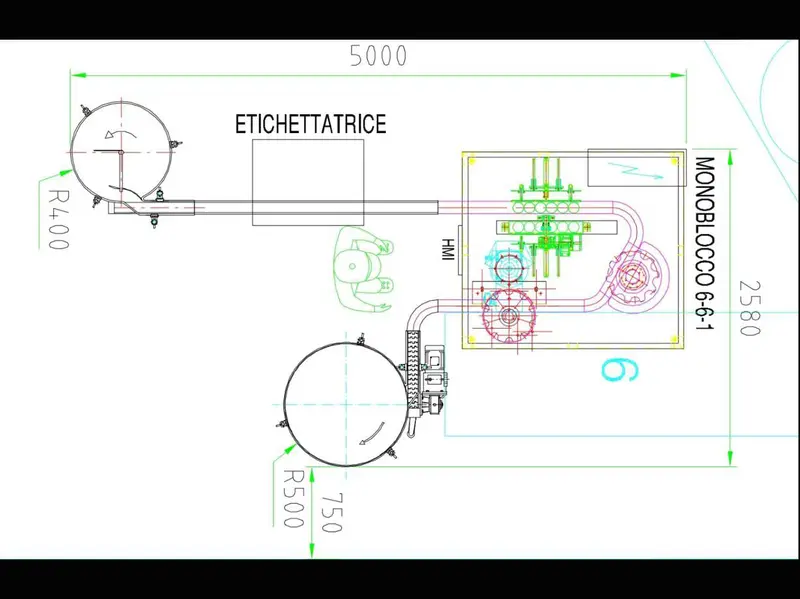

Used bottling line composed of filling monoblock + labeling machine year 2013

Introduction to the Used filling monoblock + labeling machine

The used bottling line, which consists of a filling monoblock and a labeling machine from 2013, provides a reliable solution for medium-sized production needs. Therefore, the system offers high operational efficiency, minimizes errors, and enhances operator safety through integrated safety protections. As a result, it ensures smooth operation and improves overall productivity.

Comac SMARTBLOCK 6-6-1 filling monoblock

The Comac SMARTBLOCK 6-6-1 filling monoblock guarantees maximum precision in the isobaric filling process. Specifically, the 6-6-1 model features six filling valves, a crown cap head that handles 26mm caps, and six rinsing clamps on the rinsing machine that ensure efficient bottle cleaning before the filling process. Consequently, this system works well for beer bottling, which requires strict control of pressure and temperature to maintain consistent quality and a long shelf life. In addition, it helps minimize waste while maximizing production efficiency.

Isobaric filling and process precision

In the isobaric filling process, the system maintains the product in optimal conditions throughout the bottling procedure. The fixed nozzle remains in place throughout the filling cycle, ensuring consistent product dispensing in each bottle. Thus, it reduces waste and significantly increases line efficiency. Moreover, this method guarantees a stable product environment, preserving quality during each cycle.

Line speed and production capacity

The line operates at a speed of 700 bottles per hour (bph), making it suitable for small to medium-sized productions. With this speed, the line meets a wide range of production requirements while maintaining high precision and quality standards. Furthermore, the manual head adjustment on the Enos Base labeling machine, also from 2013, allows for quick customization of labels based on bottle type and production needs. As a result, the machine applies adhesive labels to bottles with high precision and consistency.

Enos Base labeling machine

The Enos Base labeling machine runs continuously in a linear fashion. Due to its technology and manual head adjustment, it allows for quick adaptation to various bottle sizes and formats. It applies adhesive wraparound labels. Additionally, the machine includes safety protections that ensure operator safety and reduce the risk of accidents during operation. As a result, it offers flexibility and reliability in a variety of production environments.

Bottle loading and transport system

The loading table plays a crucial role in loading and unloading bottles, streamlining material flow and improving operational efficiency. Meanwhile, the conveyors connect the filling monoblock and the labeling machine, transporting bottles quickly and safely throughout the process without compromising product quality. In this way, the transport system ensures smooth bottle handling and reduces the risk of damage or contamination during production.

Line maintenance and safety

The system provides operation and maintenance manuals (of the filling monoblock), enabling operators to perform quick and effective interventions to keep the line running smoothly. Thus, it minimizes downtime and enhances the overall reliability of the system. In addition, the safety protections on both the monoblock and the labeling machine meet safety standards and reduce the risk of injury during operation. Therefore, operators can work with confidence, knowing that their safety is a priority.

Conclusion on the Used filling monoblock + labeling machine

In conclusion, this used bottling line composed of filling monoblock + labeling machine year 2013 offers a robust, high-performance solution for beer bottling. The combination of isobaric filling, high-precision labeling, and an efficient transport system ensures continuous production, reduces maintenance costs, and increases overall profitability. As a result, it is an ideal choice for those looking for a cost-effective yet reliable solution for their bottling needs.