Description

Used Bottle Dryer Matrix year 2012 12000 bph

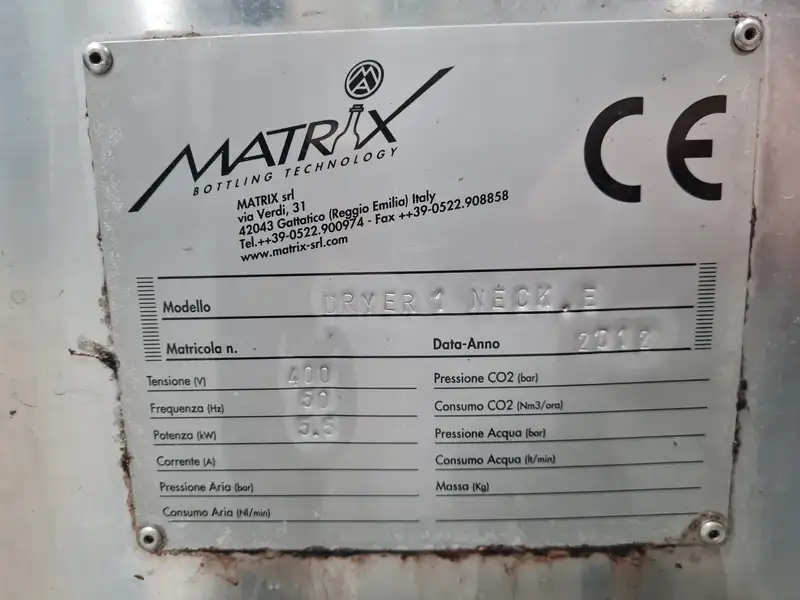

The Used Bottle Dryer Matrix year 2012 12000 bph provides a linear drying solution for bottles in high-speed bottling lines. The Italian manufacturer Matrix built this model in 2012 and named it Dryer 1 neck. The system, therefore, uses targeted airflow to dry the neck area of each bottle efficiently. It processes up to 12,000 bottles per hour, which enables seamless integration into automated bottling systems.

Mechanical Configuration and Operating Features

This linear system guides bottles through a single-entry point, which ensures precise flow control and consistent alignment during drying. The Used Bottle Dryer Matrix year 2012 12000 bph includes six drying heads that direct airflow specifically to the neck. As a result, the unit delivers highly effective drying before labeling or secondary packaging.

In addition, the machine handles all bottle formats without requiring mechanical changeovers. Consequently, operators can switch between formats quickly, maintaining flexibility across different production needs. Moreover, the uniform layout of the drying heads guarantees consistent results regardless of bottle size or shape.

Because of its modular construction, technicians can perform cleaning and inspection operations with minimal downtime. Similarly, maintenance staff can access internal components without dismantling adjacent units.

Dimensions, Electrical Supply, and Energy Use

The machine measures 1000 mm in length, 1000 mm in depth, and 2000 mm in height. These compact dimensions allow technicians to install the dryer easily within standard bottling environments. Furthermore, its footprint prevents interference with upstream and downstream machinery.

The Used Bottle Dryer Matrix year 2012 12000 bph operates on 400 Volts, at 50 Hz, and consumes 5.5 kW. These values match typical European industrial standards. Therefore, engineers can connect the unit without additional power conversion or infrastructure changes. In terms of energy efficiency, the machine balances high output with relatively low consumption.

Additionally, the robust frame ensures mechanical stability during continuous use. As such, it supports uninterrupted production in demanding environments.

Safety Systems, Integration, and Operational Status

Matrix equipped the unit with comprehensive safety systems, which comply with regulations in force at the time of manufacture. These include emergency stop buttons and protective panels, both of which ensure operator safety during regular operation and maintenance. Moreover, these safeguards reduce the risk of accidents and equipment damage.

The machine currently remains in ready-for-operation condition. For this reason, technical teams can deploy it without preliminary servicing or calibration. Moreover, its single-bottle entry system facilitates easy alignment with conveyors and auxiliary modules. Therefore, the Used Bottle Dryer Matrix year 2012 12000 bph supports fast mechanical integration into existing lines.

Likewise, the linear design improves flow continuity and minimizes disruption during installation. In turn, this reduces project lead times and setup costs.

The machine will be available starting from January/February 2026.

Technical Summary of the Used Bottle Dryer Matrix year 2012

Production teams who require reliable bottle drying between filling and labeling stages can depend on the Used Bottle Dryer Matrix year 2012. Not only does it support high-speed lines, but it also adapts to all container types with minimal effort. Furthermore, its six-head configuration, compact structure, and straightforward power requirements make it ideal for industrial bottling environments.

In conclusion, the Used Bottle Dryer Matrix year 2012 combines mechanical simplicity with high functional reliability. Ultimately, it provides consistent drying performance, flexible layout options, and safe operation—key factors for efficient and scalable production.