Description

Used Bottle Diverter APSOL 3500 bph

The Used Bottle Diverter APSOL 3500 bph efficiently redirects bottle flows within high-speed bottling and packaging lines. Its dual-path configuration, in particular, allows the system to dynamically control product direction, thereby improving distribution toward parallel lines or accumulation zones. Consequently, this diverter increases plant flexibility, optimizes output, and significantly reduces bottlenecks. As a result, it becomes an essential component in the optimization of continuous production lines.

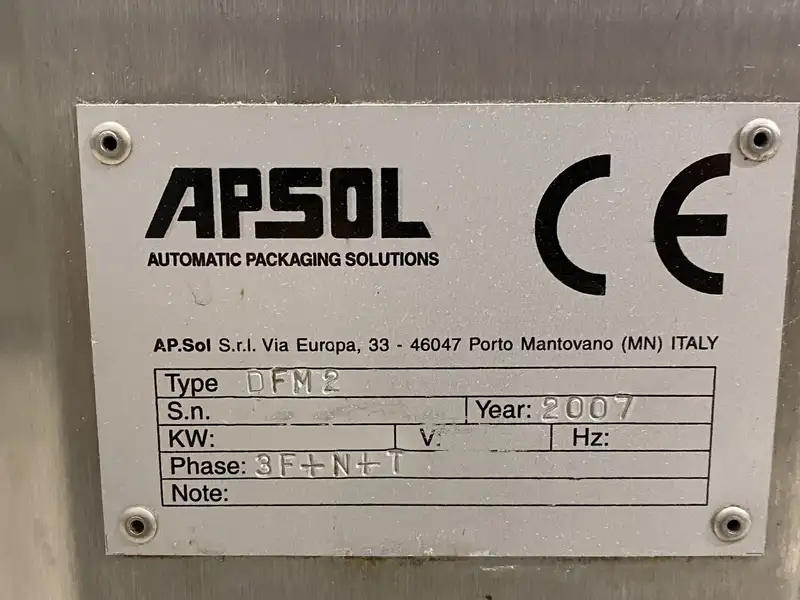

Structural Design and Technical Dimensions

APSOL manufactured the DFM2 model in 2007. The machine is currently ready for installation. Since the frame is built from stainless steel, it ensures durability and resistance in demanding industrial environments. In addition, the compact dimensions—1400 mm in length, 1000 mm in depth, and 2300 mm in height—allow the Used Bottle Diverter APSOL 3500 bph to integrate easily into tight spaces. Therefore, engineers can implement it without modifying existing layouts.

Performance and Operational Capacity

The Used Bottle Diverter APSOL 3500 bph handles a nominal capacity of 3500 bottles per hour. Accordingly, this speed suits high-output production facilities. Furthermore, the diverter system provides smooth, synchronized transitions that prevent both accumulation and bottle damage. As such, it works ideally for managing multiple product flows during filling, labeling, or packaging phases. In this context, the system ensures maximum product integrity while maintaining operational continuity.

Control via OMRON PLC

An OMRON PLC system controls all machine operations. Because of its reliability and precision, the controller effectively manages diverter positioning, sensor readings, and switching logic in real time. Moreover, the interface allows technicians to quickly configure settings according to production needs. Thanks to this capability, the Used Bottle Diverter APSOL 3500 bph adapts immediately to layout or format changes. Consequently, it minimizes downtime and ensures a stable operational flow.

Power Supply and Energy Consumption

The device operates on a 400 Volt three-phase power supply, consumes 2 kW, and runs at 50 Hz. Despite its industrial performance, the machine maintains a low energy profile. For this reason, the Used Bottle Diverter APSOL 3500 bph integrates seamlessly into existing bottling lines, even where power limitations exist. Moreover, it complies with all relevant European energy efficiency standards, reducing operational costs in the long term.

Safety Systems and Technical Documentation

The machine includes both active and passive safety features, such as protective barriers and emergency stop buttons, all compliant with current safety directives. Additionally, APSOL provides comprehensive manuals with detailed electrical diagrams and scheduled maintenance procedures. As a result, operators can install and operate the machine autonomously. Moreover, the documentation supports faster troubleshooting, which increases overall system uptime.

Technical Conclusion

In summary, the Used Bottle Diverter APSOL 3500 bph provides a robust and flexible solution for intelligent bottle flow management. Not only does it offer precise OMRON-based control, but it also guarantees compatibility with modern bottling environments. Therefore, engineers can confidently deploy it in either end-of-line applications or intermediate production stages. Overall, its reliability, integration capacity, and performance make it a strategic asset in any high-efficiency bottling facility.