Description

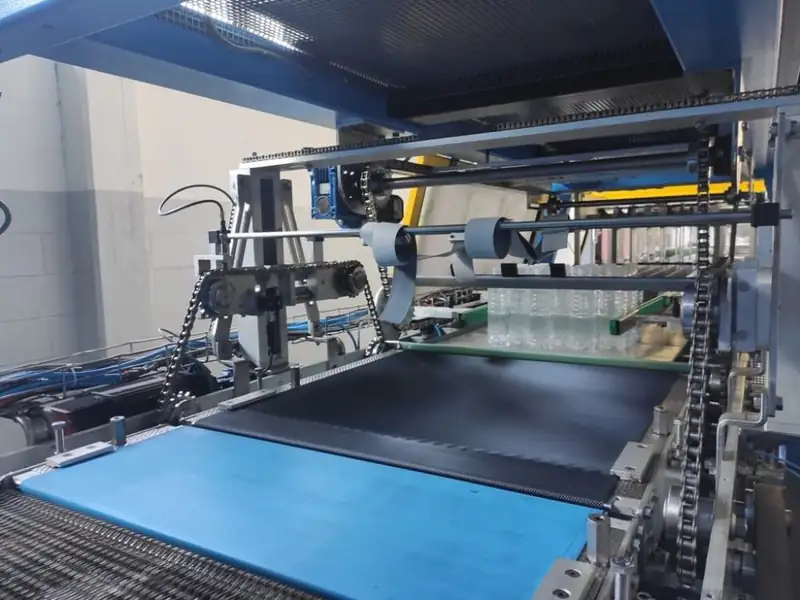

Used Automatic Shrink Wrapper Dimac 2008

This Used Automatic Shrink Wrapper has been manufactured in an EU member nation, specifically, it was made in Italy. The machine meets the requirements of the machinery directive 98/37CE.

This conformity is certified and the “CE” marking is present on the machine which notifies compliance.

The Used Automatic Shrink Wrapper was designed and built for packaging different types of sealed products, food and non-food; vacuum-packed products, flammable products, and explosives.

It is produced in several versions and, on request, can be made with special materials, depending on the

different operational and production needs; the illustration depicts the packaging schemes that are possible to get.

The high production capacity of the Automatic Shrink Wrapper makes this series of these machines suitable for installation in a packaging line in industrial environments.

For its use, it is necessary the continuous presence of an operator who must check its functionality, the

operational phases and provide for the supply of packaging material.

Packing and unpacking of the machine

The packaging is made, with containment of the overall dimensions, also according to the type of transport adopted.

To facilitate transport, the machine is shipped divided into suitably protected and packaged subsets.

The packaging contains all the information necessary for loading and unloading.

Some parts, especially the electrical ones, are protected to prevent moisture or other atmospheric agents from damaging them.

When unpacking, it checks the integrity and exact quantity of the components.

It is important to properly dispose of packaging material in compliance with current laws.

The packing can be executed in the following ways:

- A) with nylon protection

- B) on a platform, with nylon protection

- C) in a wooden box

- D) with barrier bags

This machine represents the biggest development in the shrink packaging industry, thanks to the the touch screen panel.

Operators can control all parameters of the machine, and they can also connect to a centralized production data management network. The highest level of monitoring can be achieved by modem for problem diagnosis, configuration, and program updates.

This machine is in good condition. So it has all the accident prevention protections and user manuals. Currently, it is still in production