Description

Used Automatic Microfilter Innotec 1997

INTEC MICROFILTER NOW INNOTEC

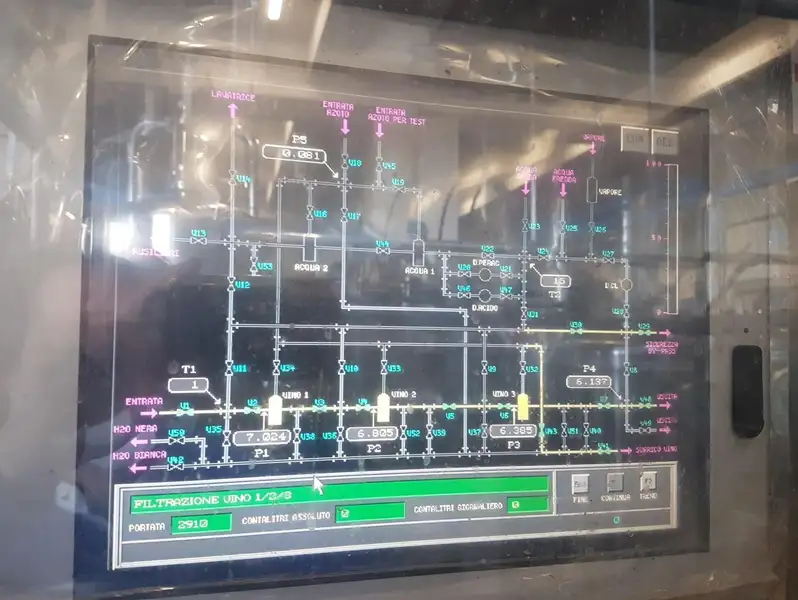

Automatic Microfilter year 1997 CE marked, INNOTEC, on SKID dimensions 3,7m x 1,5m.

– Process speed at 10,000 bottles/h controlled with litre-counter

– 3 Housings of microfiltration 12 candles 30″ and one of 40″ Connection code 7

– 2 Housings for water filtration for rinsers and washes with 5 candles 30” connection code 7

– Siemens S7 PLC with network card for remote control with VPN, expandable, because it was replaced

with a more powerful one because it was full, new operator panel

– Bubble test with automatic drains and TEST OK report, in order to have the machine ready to start in

the morning

-Steam inlet to sterilize the filler with automatic valve and inserted in the cycles that can be modified

– Weekly programming of washing starts, production cycles, sanitization, sterilization, membrane

washing, all modifiable

– Automatic DOSATRON pumps for Hypochlorite, Peracetic and Soda

– All valves have feedback to know if they are open and closed and respect recipes without errors of

valves not under control.

– Graphs of pressure, temperatures and valve positions over time, in order to be able to analyze the

process contextualised over time