Description

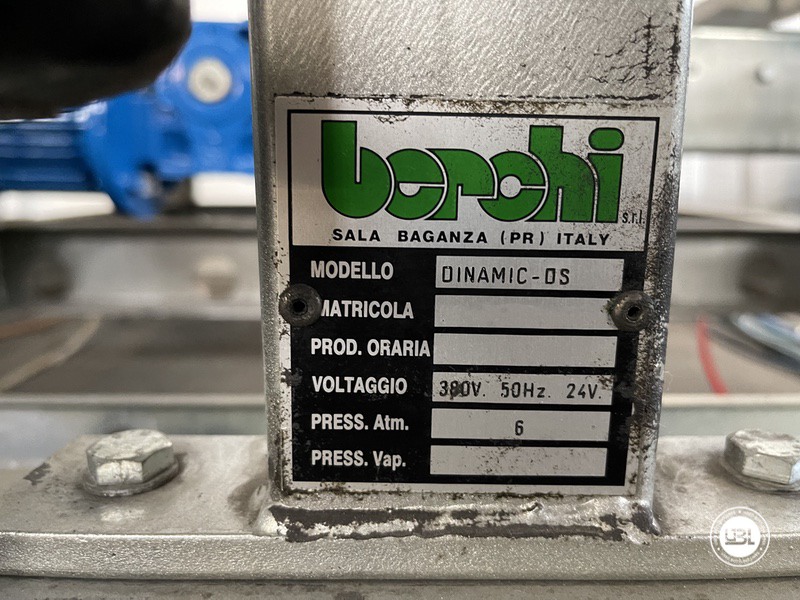

Used Automatic Depalletizer brand Berchi model Dynamics DS with plc Siemens s12

Berchi Used Depalletizer with automatic feeding has all the necessary safety features to carry out the production in safety for all the operators of the bottling line. The loading roller conveyors for full pallets can contain up to a maximum of 3 pallets. Both the mechanical and PLC components of the Berchi Used Depalletizer have been reworked.

This supply of the Used automatic Depalletizer does not include the bottle unloading and alignment table. And, it must be developed and structured on the basis of the bottle formats that the customer decides to produce.

How does this used Berchi depalletizer work?

The method used by Berchi as Used depalletizer is transferred by sliding; so then allows you to work with bottles of different types and materials (glass, PET, etc.). This without making adjustments, thus allowing immediate format change.

Completely rebuild, so with the replacement of the old obsolete PLC it’s mounting a Siemens S12 with Siemens HMI panel.

Technical Data of Used Depalletizer:

The air required 6 bar +/- 10%

Air consumption, about 9 m3 / h

Weight 4500 kg

Capacity up to 40,000 b / h depending on the container and pallet height.

Low dislocation of the Berchi depalletizer

The maximum height of the pallet is 2100 mm

Automatic removal of interlayers

Pallet type 1200×800 and 1200×1000, so it is versatile.

Siemens S12 control is available for Berchi Depalletizer.

The used automatic depalletizer worked 30,000 hours before undergoing a complete mechanical and electrical overhaul. Speed 40,000 BPH for a glass bottle of different sizes.

In the case of a request for a mechanical warranty period, one separate offer will be provided. This is for the installation and the start-up.

Our technicians must be present for the installation as a supervisor, even if the buyer wishes to carry out the assembly by himself. That is in order to confirm the guarantee on the replaced parts of the machinery.

The machine is currently disassembled in the warehouse, and so ready for shipping.