Description

Used Automatic Depalletizer ACMI 1600 plastic crates/hour

The Used Automatic Depalletizer ACMI 1600 plastic crates/hour, model Rasar D180, operates as a fully automatic system for bottom-feed depalletizing of 1-liter glass bottles packed in 12-bottle plastic crates. Specifically designed for high-speed bottling lines, the system processes up to 1600 boxes par hour. Moreover, its modular frame allows seamless integration into existing production lines. Although it is currently dismantled and in storage, the unit remains in full working condition, ready for reinstallation.

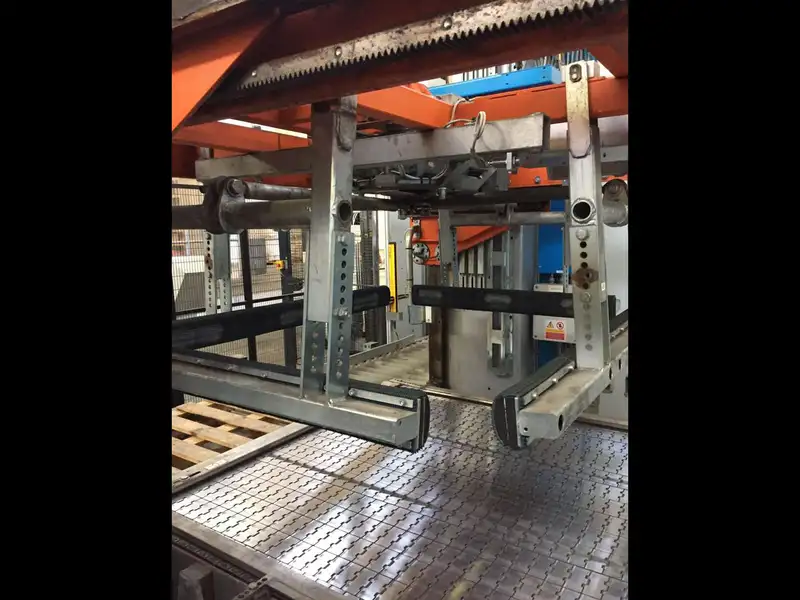

Depalletizing Structure and Operating Mode

The Used Automatic Depalletizer ACMI 1600 plastic crates/hour utilizes a conventional automatic vertical structure to handle pallet loading from below. This configuration, therefore, ensures optimal stability and precision during the handling of glass containers. In addition, the machine includes an integrated pallet magazine, which automatically feeds pallets into the process without requiring manual assistance. Consequently, the system improves line efficiency and minimizes stoppage time. Furthermore, thanks to its automated design, the machine reduces labor dependency and enhances repeatability.

Container Compatibility and Format Handling in the ACMI depalletizer

This machine specifically handles 1-liter glass bottles arranged in 12-bottle plastic crates. As such, it suits production lines that deal with fragile, heavy, or pressurized containers. In terms of compatibility, the Used Automatic Depalletizer ACMI 1600 plastic crates/hour meets standard industry requirements for crate and bottle handling. Additionally, it ensures accurate transfer from pallet to crate and then to the conveyor system. Not only does the equipment offer reliable performance, but it also reduces the risk of damage during transfer. Similarly, its precise control mechanisms help optimize changeovers when switching formats.

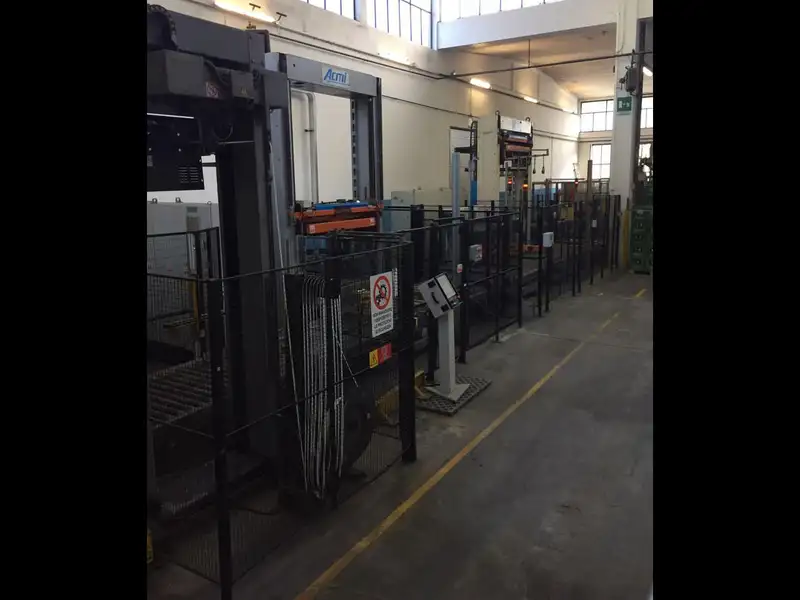

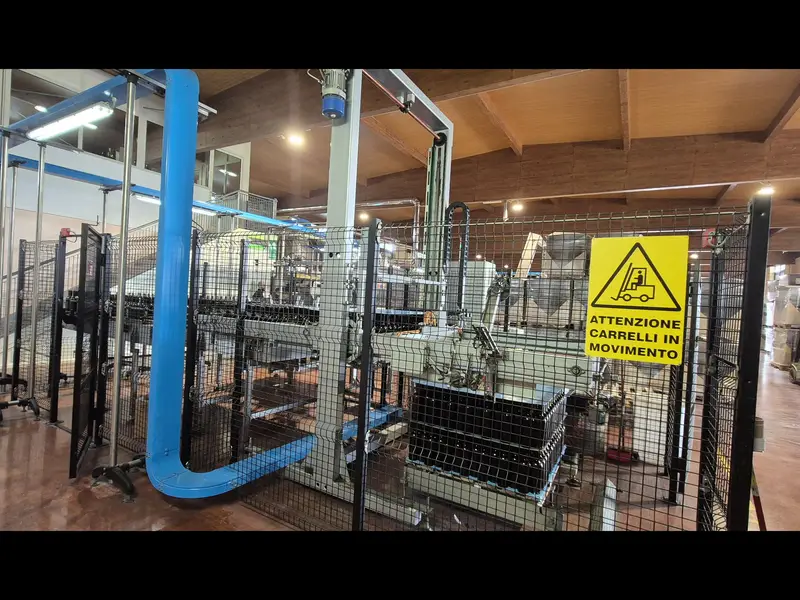

Safety Features and Electronic Control of the ACMI depalletizer

Engineers equipped the machine with certified safety systems that meet all current regulations for automated equipment. These features include physical guarding, sensor-based detection, and emergency stop functions in critical zones. As a result, the machine ensures safe operation in industrial environments. The Used Automatic Depalletizer ACMI 1600 plastic crates/hourruns under the control of a Siemens PLC, which manages operations through real-time sequencing and diagnostics. In particular, the PLC simplifies fault detection, thereby reducing downtime. Moreover, its open architecture supports easy integration into plant-wide SCADA systems. Therefore, users benefit from complete process visibility and responsive control.

Technical Documentation and Operational Status

In terms of documentation, the Used Automatic Depalletizer ACMI 1600 plastic crates/hour includes full technical manuals. These documents cover installation, electrical schematics, PLC logic, and communication interfaces. As a result, maintenance teams can easily service and adapt the system as needed. Although the machine is currently stored and disassembled, all core components remain available and intact. Consequently, technicians can reassemble and recommission the unit with minimal intervention. In summary, this depalletizer offers a reliable, automated, and efficient solution for bottle crate depalletizing in high-speed production environments.