Description

Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph

GEA ASEPTIC BLOW FILL SYSTEM ABF 2.0

Fully aseptic blowing, filling and capping system featuring H2O2-based preforms sterilization.

Introduction to the Aseptic Filling Line SIPA GEA for Milk up to 48,000 bhp

The used aseptic filling line SIPA GEA for milk up to 48,000 bottles per hour delivers a highly efficient and technologically advanced solution for the packaging industry. Specifically, this system ensures high-quality standards and food safety by using machines from 2018. Moreover, it processes milk in 235 ml bottles with plastic screw caps and a 38 mm neck. The line has only 900 operating hours.

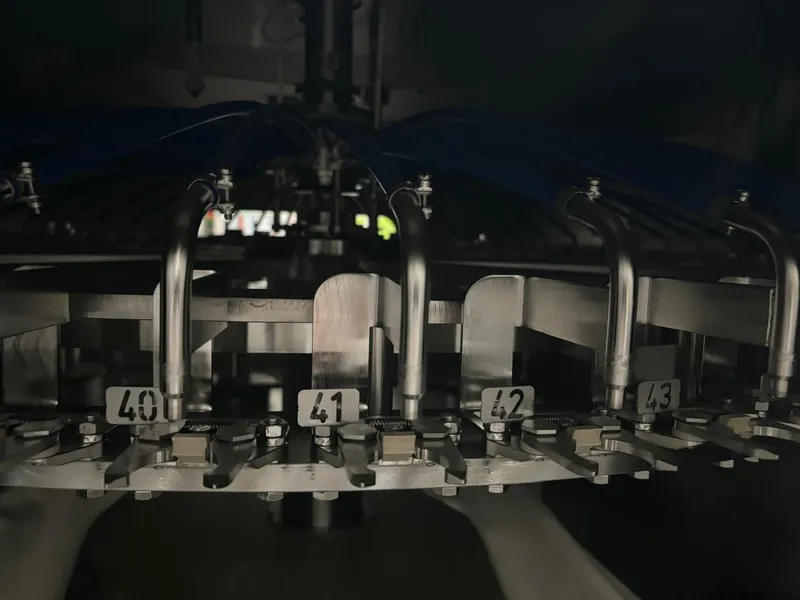

SIPA SFR 24 EVO Blow Molding Machine of SIPA and GEA aseptic line

The SIPA SFR 24 EVO blow molding machine, manufactured by GEA in 2018, produces high-quality bottles from PET preforms. As a result, it maintains continuous and uninterrupted production, ensuring efficiency. In addition, the SFR 24 EVO model optimizes energy consumption and shapes containers with precision, making it ideal for high-performance lines like the Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph.

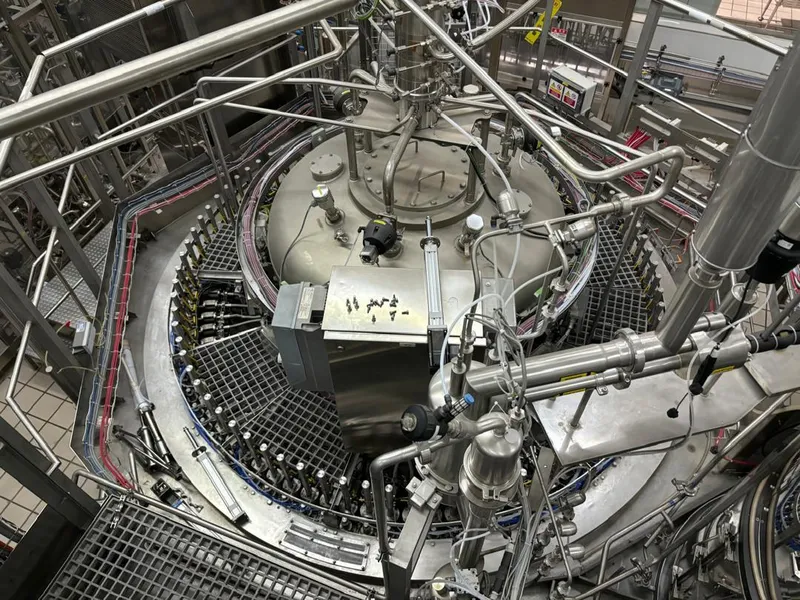

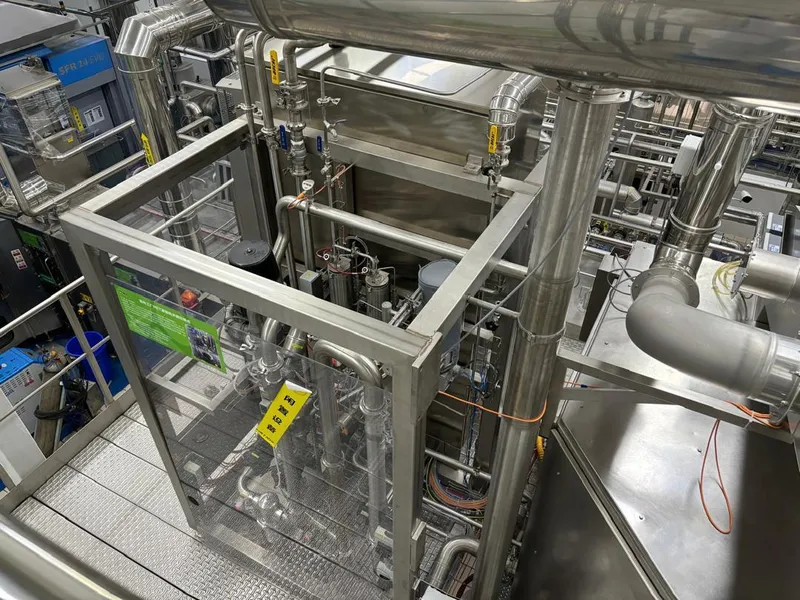

GEA Filling Machine

The GEA filling machine, also from 2018, controls the core of the system. Since it fills milk in an aseptic environment, it preserves the organoleptic and microbiological properties of the product. Furthermore, the SIPA and GEA aseptic line doses the product with precision and operates reliably, reducing waste and improving overall efficiency. Consequently, it enhances productivity while maintaining strict hygiene standards.

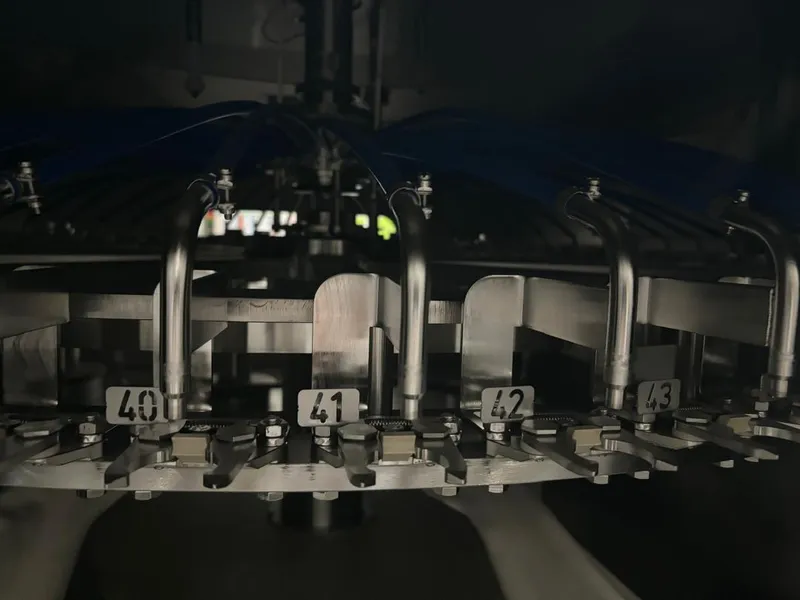

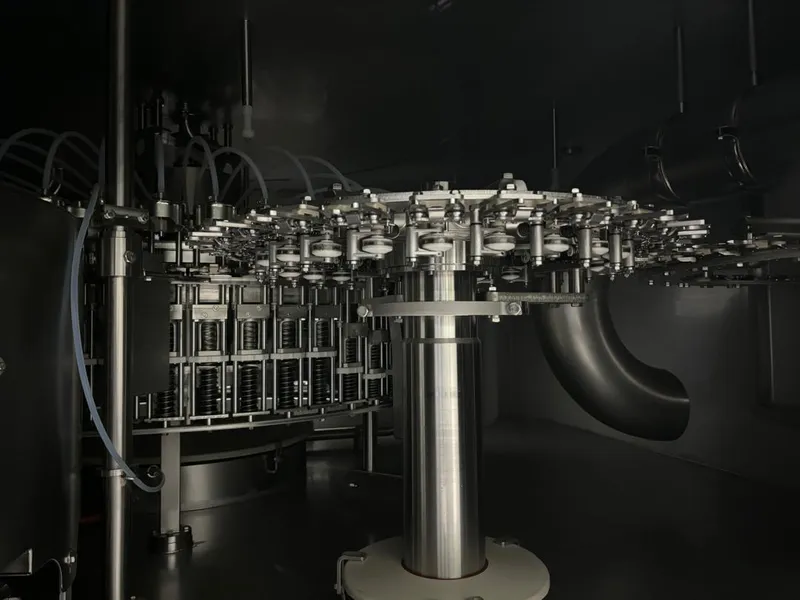

Arol Capping Machine for Secure Sealing

The Arol capping machine, built in 2018, securely seals bottles with plastic screw caps. Likewise, it ensures a tight closure and matches the 38 mm neck perfectly. As a result, its integration into the line guarantees fast and uniform capping, preventing leaks and maintaining product integrity.

Aerzen GM25S Compressor

The Aerzen GM25S compressor, from 2018, powers the blow molding process. In particular, it supplies high-quality compressed air, which the machine requires for shaping PET bottles. Notably, its efficiency and reliability support seamless production. Therefore, it plays a crucial role in maintaining high-speed output.

Operational Condition and Limited Use

The Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph processed only around a hundred production cycles, keeping the machines in excellent condition. Thus, the limited use ensures optimal performance and minimizes wear, making this system nearly new in operational terms. Additionally, well-maintained components extend the machine’s lifespan, reducing the need for costly replacements.

Line Efficiency and Performance

The Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph combines high-performance machines designed specifically for milk processing. Consequently, it enables fast and efficient production while meeting strict aseptic standards. Moreover, the line reaches speeds of up to 48,000 bottles per hour, making it a strategic choice for producers competing in high-demand markets. Similarly, it supports companies looking to improve productivity without increasing operational costs.

Advantages of a High-Performance of Used Aseptic Fllling Line SIPA GEA for milk up to 48.000 bph

The used aseptic filling line SIPA GEA for milk up to 48,000 bottles per hour provides a cost-effective alternative to new equipment without sacrificing quality or efficiency. For instance, the integration of essential components—blow molding machine, filling machine, and capping machine—ensures a smooth and highly productive workflow. In contrast, purchasing a new line would require a significantly higher investment. Additionally, this used SIPA and GEA aseptic line system allows companies to scale up production quickly without long installation lead times.

Conclusion of the Used Aseptic Filling Line SIPA GEA for Milk up to 48,000 bph

The used aseptic filling line SIPA GEA delivers a reliable and high-performance solution for milk processing. Given these points, its advanced technology, excellent machine condition, and high-speed production capabilities make it the ideal choice for businesses requiring efficiency and precision. Ultimately, investing in this line allows manufacturers to increase output while maintaining product quality. Used Aseptic Fllling Line SIPA GEA for milk up to 48.000 bph in excellent status of maintenance.