Shrink Wrapper

Ref: FA30

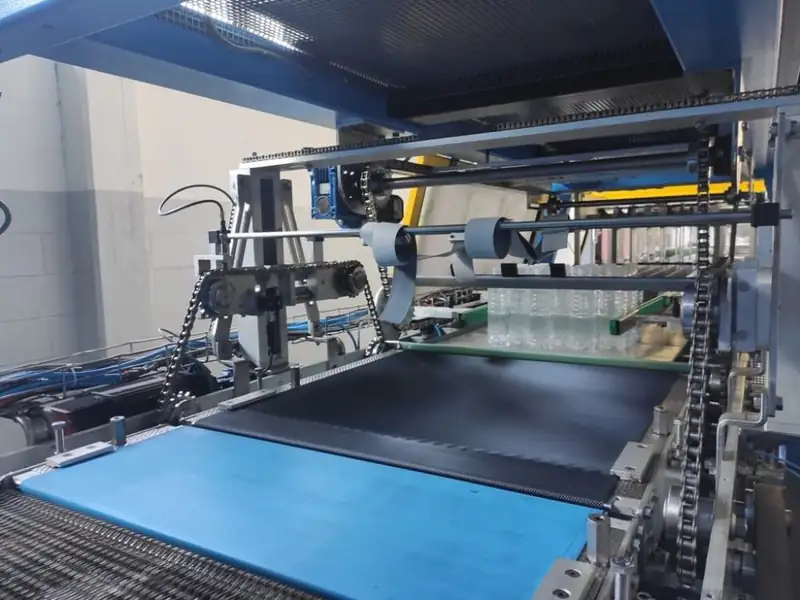

SMI GROUP SK 602P

Sold

Manufacturer:

SMI GROUP

Model:

SK 602P

Year:

1999

Speed:

80000 BPH

Products:

Alcohol, Beer, Dairy, Detergents, Juice, Oil, Soft Drinks, Spirits, Spumante, Tea, Vinegar, Water (Sparkling), Water (Still), Wine (Sparkling), Wine (Still)

Details

Measurements:

Width: 15480mm

Length: 1800mm

Height: 2500 mm

Safety features:

Yes

Manuals:

Yes

Film type:

Neutral

Tray:

Available

Operating type:

Automatic

Works with printed film:

Yes

Machine feed type:

Straight

Bundles/minute:

120

Shrink Wrapper

Ref: FA30

SMI GROUP SK 602P

Sold

Manufacturer:

SMI GROUP

Model:

SK 602P

Year:

1999

Speed:

80000 BPH

Products:

Alcohol, Beer, Dairy, Detergents, Juice, Oil, Soft Drinks, Spirits, Spumante, Tea, Vinegar, Water (Sparkling), Water (Still), Wine (Sparkling), Wine (Still)

Request information

Further information, photos and layouts are available for each machine. Click on Request information in case you need more data.

DISCLAIMER: The operational status of each machine is monitored on a monthly basis. Therefore we will promptly update the current status of the machine only at the time of your request.

Description

- Machine bearing frame made of sand-blasted and powder-painted steel

- The machine is equipped with sliding protection doors in anodised aluminium featuring a rounded shape which let all the motors (featuring low energy consumption) be placed externally if compared to the mechanical groups they activate. The closing system of doors is equipped with a slow-down device, which accompanies the door smoothly in its final phase of closure

- Continuous motion product grouping device, with electronically synchronized fingers made of plastic material

- For life lubricated bearings

- Infeed conveyor with chains made of thermoplastic material featuring low friction coefficient and a motorized system of oscillanting laning guides

- Cardboard magazine situated beneath the infeed conveyor, adjustable according to the blank size

- Continuous motion rotary cardboard blank picker, equipped with suction cups

- The unwinding of the film reels, placed in the lower part of the machine, is controlled by a brushless motor, which ensures the film constant tension. There are two film reels: one is operating, the other one stands by. When the operating film reel is over, a manual sealing bar joins the films. In order to facilitate the replacement of the film reels the machine is equipped with a dedicated reel truck. The mandrels feature a pneumatic blocking system and when the film ends, a special device stops the machine

- Before the pack enters the shrinking tunnel, the film is cut by a knife equipped with motorized blade and then wrapped around the group of containers and overlapped on the bottom of the pack. The adjustment of the film length is electronic

- Compact knife group with film cutting blade driven by a direct drive brushless motorization

- Automatic centring system for printed film provided with marks

- Machine electrical cabinet with air conditioner

- The shrink tunnel features state-of-the-art technical solutions reducing energy consumption and ensuring an eco-friendly working process. The tunnel conveyor belt is made up of fibreglass bars, driven by side chains (®SMI). Thanks to the precise analysis of thermodynamic phenomena generated by the shrink process, the tunnel distributes hot air flows in an efficient and homogeneous way on the pack, thus ensuring its excellent quality at the end of the process. Shrink resistances are positioned on the side walls of the tunnel