Various Equipment

Ref: AT38

Procomac UNICLEAN 2R 2-OP1-BA-A-20 1999

In storage

Manufacturer:

Procomac

Model:

UNICLEAN 2R 2-OP1-BA-A-20

Year:

1999

Details

Measurements:

Width: 3008mm

Length: 2326mm

Height: 2585 mm

Electrical data:

V: 400V

kw: 7kw

hz: 60hz

Weight:

2000 kg

Safety features:

Yes

Manuals:

Yes

Various Equipment

Ref: AT38

Procomac UNICLEAN 2R 2-OP1-BA-A-20 1999

In storage

Manufacturer:

Procomac

Model:

UNICLEAN 2R 2-OP1-BA-A-20

Year:

1999

Request information

Further information, photos and layouts are available for each machine. Click on Request information in case you need more data.

DISCLAIMER: The operational status of each machine is monitored on a monthly basis. Therefore we will promptly update the current status of the machine only at the time of your request.

Description

Procomac UNICLEAN 2R 2-OP1-BA-A-20 1999

The Uniclean units is a modular system comprising five units.

- Thinned NaOH stocking unit

- Thinned HNO3 stocking unit

- Electrical panel

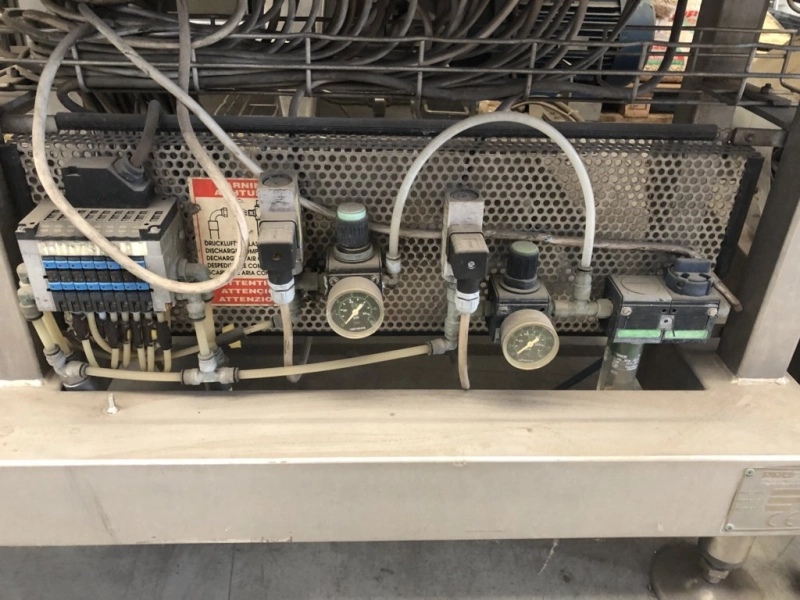

- Pneumatic panel

- Heat exchanger unit

The purpose of this system is to sterilise the machine at the end of each work shift and whenever necessary for hygienic purposes for example, before activating the production line after a lengthy line stoppage (week-end).

NaOH Dilutions 1+3% – HNO3 Diluitions 1+3%

Consumptions

Water 20 M3/H – Steam 750 Kg/H – Air 3 Nm3/H