Description

Modular labeling machine 10 heads

| Modular labeling machine | Cold glue

• 4 stations: Front/back, seal L, neck ring

self-adhesive • 3 stations: Front/back, neck ring |

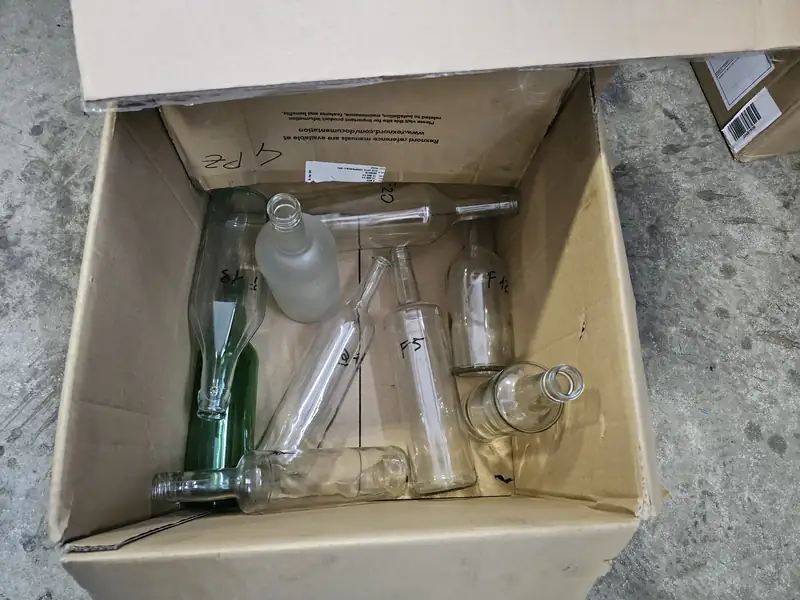

| Bottles : | round/square |

| Label stations nr.: | N. 3 self-adhesive stations

N. 3 Cold glue stations |

| Central diameter Ø: | Ø 960 |

| Plates nr.: | 10 |

| Length of the labels min/max: | 10/150 |

| Height of the label min/max: | 15/200 |

| Container diameter/height min/max: | Ø 30/80 mm – Altezza min/max 100/400 mm |

| Plate transmission | Motorized plate |

| Optical centering | Yes |

| Special inlet stars | No. 3 multi-format in/out stars D 50->120 mm |

| Industria 4.0 | yes predisposed |

| other request | Double screw input in phase |

| Max speed request: | 6.500 bph |

Modular labeling machine: basic machine composition

1. System built according to CE regulations

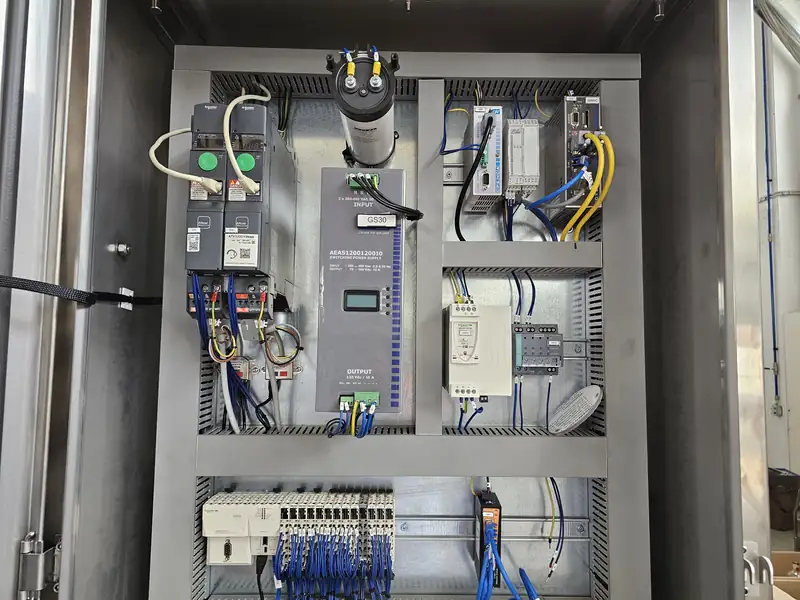

2. Machine operation via PLC (Schneider)

3. Touch-screen control panel for labeler functions installed on a mobile and rotating support

4. Automatic variation of production speed with inverters and detection sensors installed on the conveyor belts

5. Light column indicating the operating status of the labeler

6. Electrical cabinet fixed internally to the machine body.

7. Accident prevention protections consisting of:

➢ On the screw front, with two swing doors

➢ On the labeling station front, single-part circulars a

vertical lift

8. Height-adjustable upper head for different containers with gearmotor, panel adjustment, and automatic stop limit switch

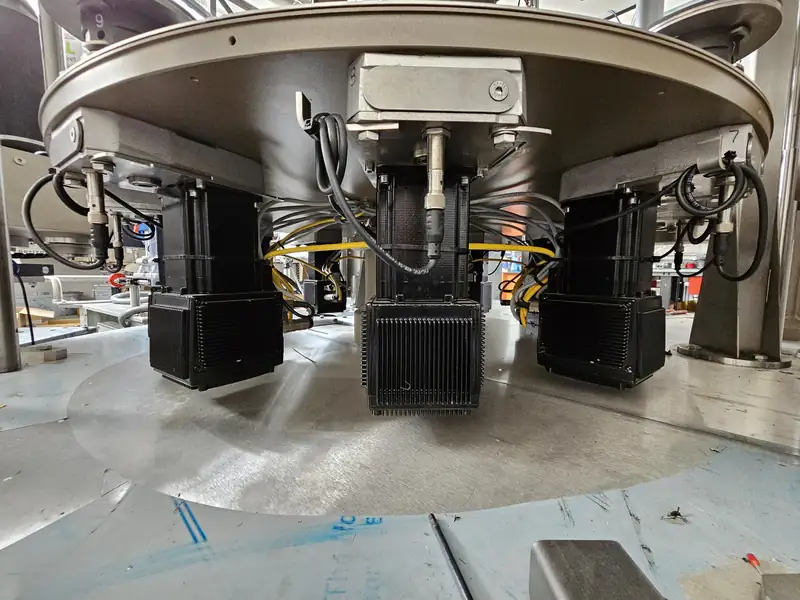

9. Plate rotation via electronic cams

10. Shaped plates

11. The transmission between the plate and the motor occurs via a maintenance-free gear reducer

12. Quick plate change

13. The body of plates removable from the lower carousel (complete with all their transmission)

14. Double inlet auger with stop-in phase

15. N. 3 40M adhesive labeling stations, including:

· Stepper motor

· Machine stops after two labels are missing on the reel

· Memory for 200 different labels

· Automatic missing label recovery function

· 4-axis adjustment system, without tools

· Reel exhaustion sensor

· Standard photocell for labels FOR TRANSPARENT

16. L-shaped sealing pliers with 4 DIVISIONS

17. N.3 Cold glue labeling station, type: 2-2-150, including:

· Motorization with servomotor

· Automatic glue film adjustment

· Automatic washing of the drum tweezers for label removal.

· Glue pump

· Forced oil lubrication

· No greasing points

· Radial and tangential adjustment with machine in production

· MANUAL GROUP HEIGHT ADJUSTMENT WITHOUT HEIGHT CHANGE

18. Teleassistance

19. N.1 Equipment for CYLINDRICAL container format consisting of:

· Nr. 1 container introduction screws with UNIVERSAL container shape FOR BOTTLE DIAMETERS FROM 50 TO 120 MM

· Nr. 1 UNIVERSAL entry/exit star WITH HANDS

· Nr. 1 central container guide

· No. 10 clay pigeons

20. Optical centering LOGO OR WELDING following with FOLLOWER 2 system

21. N. 5 Smoothing station for labels

22. N.1 Cold glue body label or back label equipment

· N. 1 label warehouse

· N. 1 set of label-picking pallets;

· N. 1 label picking pliers drum;

· N.1 label smoothing station.

23. N.1 Label equipment for cold glue collar

· N. 1 label warehouse

· N. 1 set of label-picking pallets;

· N. 1 label picking pliers drum;

· N.1 label smoothing station.

24. N.1 Cold glue “L” seal equipment

· N. 1 label warehouse

· N. 1 set of label-picking pallets;

· N. 1 label picking pliers drum;

· N.1 set of pads and hands for the seal pliers.

Modular labeling machine standard parameters

✓ Supporting and upper structure in hot-dip galvanized steel

✓ Top and side cover in AISI 304

➢ Container transfer

The spacer screw, the input/output stars, and the central guide are made of wear-resistant synthetic material. The lateral and belt sliding guides are made of plastic

➢ Carousel

The container locking heads have a height tolerance of up to 15 mm

➢ PLATE HANDLING: ELECTRONIC CAM

➢ Self-adhesive labeling station

The self-adhesive station was created in modules independent of each other and fixed on a modular aluminum profile – Paper unwinder – Label peeling blade – Drive roller – Support paper rewinder – Electrical panel with quick connections.

Each individual group can be quickly and easily replaced.

The station is fixed to a solid mechanical structure, equipped with 4 adjustment axes, complete with format position indicators.

The technique of the Modular labeler:

The label drive motor is perfectly synchronized with the speed of the labeler detected and controlled by a single high-resolution encoder.

The label dispensing speed is variable. By stopping the machine during labeling with the label dispensed halfway, it is possible to restart without having defects in the application of the label on the container.

The paper drive roller is specifically treated to prevent glue residues from self-adhesive labels from adhering (the option is present starting from 60 MT/min modules).

Ergonomic: all adjustments take place in the upper part of the self-adhesive assembly.

All adjustments occur without tools and are indicated in red. The degree of protection is IP65.

Electronics

Digital control electronics.

Terminal for programming and storing the various types of labels (200 max).

No mechanical/manual adjustment of the speed ratio and format adjustment.

The machine stops after two labels are missing on the reel.

Automatic missing label recovery function.

➢ Smoothing

The smoothing, customized for each individual format, includes brushes and/or rollers that can be removed as a whole for replacement without the use of tools.

For certain applications, an additional smoothing device can be mounted on the belt.

➢ Transmission and main control

The transmission to all moving parts is given by alternating gears in C40 and Zellamid steel.

The central motorization is provided by a gear motor driven by an “Inverter” electronic frequency converter.

➢ Speed regulation and automatic control

The production speed of the machine is totally automatic and is variable based on the incoming flow and outgoing disposal of the containers. Furthermore, a stop device, installed at the machine entrance, guarantees a minimum accumulation of containers at the machine entrance and an automatic safety stop in the event of an accumulation of containers at the machine exit. Everything is managed by a PLC.

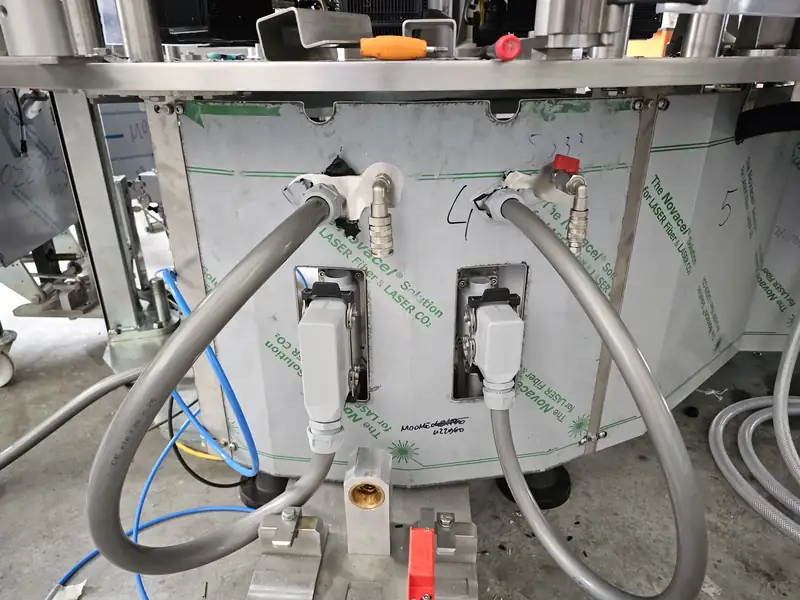

➢ Pneumatic system

Service group incorporated into the modular labeling machine with regulation valve and water separating filter ready for an existing connection.

➢ Electrical installation

CE-compliant system, ready for connection to the network. Voltage according to customer specifications. Control voltage 24 V DC

➢ Maintenance

Manual, individual, and grouped greasing points. Low-maintenance materials are used on the panel, such as sealed ball bearings and self-lubricating sliding materials. Periodic check of the oil level in the spacer screw.

The Manufacturer reserves the right to make technical changes based on what is described.

techniqueThe label drive motor is perfectly synchronized with the speed of the labeler detected and controlled by a single high-resolution encoder.

The label dispensing speed is variable. By stopping the machine during labeling with the label dispensed halfway, it is possible to restart without having defects in the application of the label on the container.

The paper drive roller is specifically treated to prevent glue residues from self-adhesive labels from adhering (the option is present starting from 60 MT/min modules).

Ergonomic: all adjustments take place in the upper part of the self-adhesive assembly.

All adjustments occur without tools and are indicated in red. The degree of protection is IP65.

Electronics

Digital control electronics.

Terminal for programming and storing the various types of labels (200 max).

No mechanical/manual adjustment of the speed ratio and format adjustment.

The machine stops after two labels are missing on the reel.

Automatic missing label recovery function.

➢ Smoothing

The smoothing, customized for each individual format, includes brushes and/or rollers that can be removed as a whole for replacement without the use of tools.

For certain applications, an additional smoothing device can be mounted on the belt.

➢ Transmission and main control, Optical centering, and electronic cams

The transmission to all moving parts is given by alternating gears in C40 and Zellamid steel.

The central motorization is provided by a gear motor driven by an “Inverter” electronic frequency converter.

➢ Speed regulation and automatic control

The production speed of the modular labeling machine is totally automatic and is variable based on the incoming flow and outgoing disposal of the containers. Furthermore, a stop device, installed at the machine entrance, guarantees a minimum accumulation of containers at the machine entrance and an automatic safety stop in the event of an accumulation of containers at the machine exit. Everything is managed by a PLC.

➢ Pneumatic system

Service group incorporated into the machine with regulation valve and water separating filter ready for an existing connection.

➢ Electrical installation

CE compliant sy