Description

Used Wine Bottling Line For Glass Bottles of 3L – 2000 BPH

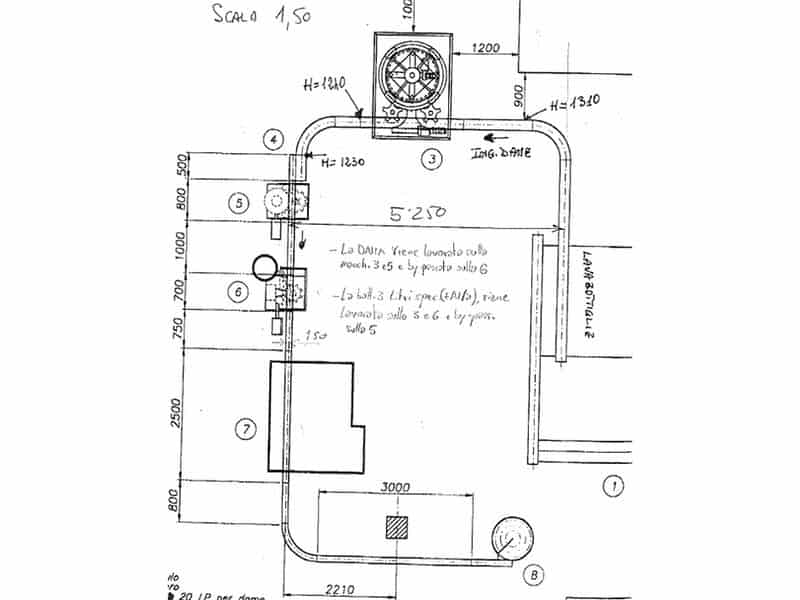

Technical features:

150 mm chain

Production: 2000 carboys per hour

Voltage: 380

Low voltage: 24v

Frequency: 50Hz

Working direction: right to the left

Worktop height: 1240mm

Carboy base format diameter: 51, 179 × 340

This line includes big italian brands, like Bardi, Bertolaso and Cavagnino&Gatti.

The bottling line ends with labelling equipment, so different packing systems can be attached as needed. This can be standard cardboard boxes or tray plus film or wrap-around system closure.

The two bottle sizes worked are 1,5L and 3 L but if needed this can be adapted for 0,75 L too. With additional payment it can be upgraded to create equipment for the inlet and outlet, the 0,75 L bottle size.

It has a satin cork corker and aluminium screw cap capper, and an 8 head labeller with two adhesive stations. It performs gravity filling for still liquids. The washer is for cleaning the new bottles inside and outside for one-way production.

Regular maintenance has been done on all equipment of the line, so it can be reassembled without critical problems.

Our professional team can help you realize this project, supporting you both in the tech department and with an engineering consultant.