Description

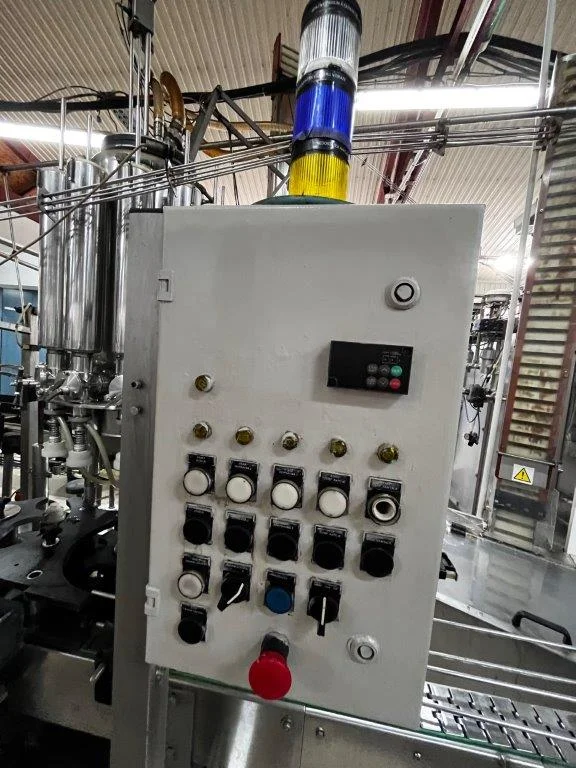

ALTEC PO 12/1 Filling and Capping Monoblock – Overview

This used ALTEC PO 12/1 filling and capping monoblock is engineered for efficient bottling operations within beverage production and industrial packaging environments. Designed to handle both PET and glass bottles, it is suitable for water and 100% fruit juices, as well as other low-viscosity still liquids. With 12 filling valves and 1 capping head, the machine offers compact, integrated performance for second hand and used bottling line applications.

Manufactured by ALTEC, the monoblock supports hot or cold filling modes for still products, making it a versatile choice for small to medium production runs. Variable speed control via a frequency regulator allows operators to adapt throughput to different container sizes and product requirements.

Technical Specifications & Performance Data

- Model: PO 12/1

- Manufacturer: ALTEC

- Year of manufacture: 2004

- Configuration: Filling and capping monoblock

- No. of filling valves: 12

- No. of capping heads: 1

- Max. capacity: up to 3,000 bph on 0.5L; up to 2,000 bph on 1.5L

- Container types: PET and Glass bottles

- Fill volumes: 0.5L, 0.85L, 1.0L, 1.5L, 2.0L

- Filling mode: Hot or Cold filling for still liquids

- Power: 3 kW

- Compressed air: 6 bar

- Dimensions (monoblock): 2300 x 1500 x 2300 mm (L x W x H)

- Stand with balance tank: 1050 x 600 x 1000 mm

- Closure system: 28 mm plastic screw cap; setup for short neck PCO 1881

- Optional closure equipment: support for 38 mm sport cap (subject to available tooling)

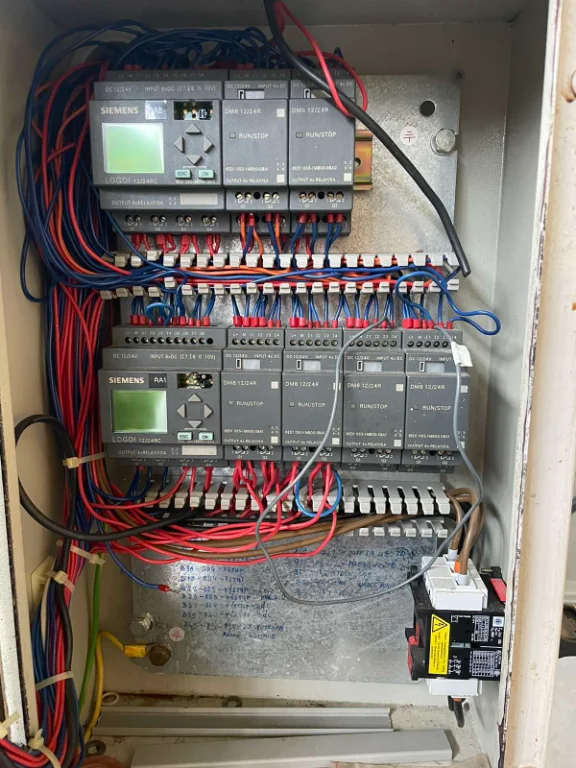

- Control: Siemens control (HMI with small display inside cabinet)

Advanced Automation & Control Systems

The ALTEC PO 12/1 integrates a Siemens control platform providing reliable automation and straightforward operation. A frequency regulator (VFD) manages the charging speed, enabling quick adaptation to production demands and bottle formats. The compact HMI located in the control cabinet gives operators access to essential machine parameters.

- Siemens control for consistent, proven reliability

- Frequency-regulated variable speed for flexible throughput

- Operator access via small integrated display

Production Line Integration Capabilities

This monoblock fits seamlessly into a used bottling line or standalone station within beverage production. It is designed for PET and glass containers and can interface upstream with a rinsing machine and downstream with labeling, inspection, and packaging equipment. Format changes are supported across multiple bottle sizes from 0.5L to 2.0L, and several format parts are included.

- Inline or standalone operation in industrial packaging lines

- Compatible with upstream rinsers and downstream labelers, inspectors, and packers

- Multi-format flexibility: 0.5L, 0.85L, 1.0L, 1.5L, 2.0L

Machine Condition & Maintenance History

The monoblock was last used in 2020 and was regularly serviced until then. It is currently dismantled and cannot be wet-tested in its current state; however, a dry run can be attempted. Technical documentation is available. The overall condition is described as solid for a second hand unit.

Operational Performance & Versatility

Optimized for still beverages, the unit handles hot-fill and cold-fill applications for 100% fruit juices and water, along with other low-viscosity, non-carbonated liquids. A 28 mm plastic screw cap setup (PCO 1881 short neck) is installed, and provisions for 38 mm sport caps are referenced, subject to availability of specific adapters and tooling.

- Ideal for Water and Juices

- Hot-fill capability for juices and heat-stable products

- Supports PET and Glass packaging

Installation Requirements & Site Preparation

Ensure adequate floor space for the monoblock and its balance-tank stand. Provide electrical power capacity consistent with a 3 kW machine and a stable compressed air supply at 6 bar. Allow clearances for changeover and maintenance access, and plan utilities routing for integration into the existing production line.

- Space envelope: approx. 2300 x 1500 x 2300 mm plus auxiliary stand

- Utilities: 3 kW electrical, compressed air at 6 bar

- Environmental: standard bottling hall conditions

Safety Standards & Compliance Certification

The monoblock is designed for operation with standard safety practices typical of bottling equipment, including guarded enclosures and emergency stop functions as configured by the OEM and integrator. Buyers should verify current regulatory compliance and safeguarding during installation and commissioning, especially when integrating with other bottling equipment within a used production line.