Description

Krones PET Block 54/8 Monobloc Filler–Capper – Overview

The Krones PET Block 54/8 is a second‑hand monobloc composed of a rotary isobaric filler and rotary screw capper for PET bottles. Engineered for beverage production and industrial packaging, this unit is ideal for integrating into a used bottling line requiring counter‑pressure filling and PCO 1881 closure application. With 54 fixed filling valves and an 8‑head capper, it delivers reliable performance on large PET formats with precise neck handling.

Technical Specifications & Performance Data

- Configuration: Monobloc Filler–Capper (filler + capper; no rinser module)

- Filling technology: Isobaric, fixed-valve counter‑pressure

- Number of filling valves: 54

- Valve pitch (center distance): 126 mm

- Capper: 8-head rotary screw capper for plastic closures

- Neck finish: PCO 1881 (short finish) – plastic screw caps

- Bottle materials: PET

- Nominal capacities: 1.5 L = 9,000–10,000 bph; 3.0 L = 7,000–8,000 bph

- Machine rotation: Clockwise

- Overall dimensions: L 3.8 m, W 3.2 m, H 2.65 m

- Approx. weight: 7,500 kg

- Reference: M302

Module Details

- Filler carousel: 54 valves, designed for carbonated beverages and counter‑pressure operation; suitable for still beverages with inerting depending on product setup.

- Capper turret: 8 capping heads optimized for PCO 1881 plastic screw caps; consistent application torque and bottle neck handling for PET containers.

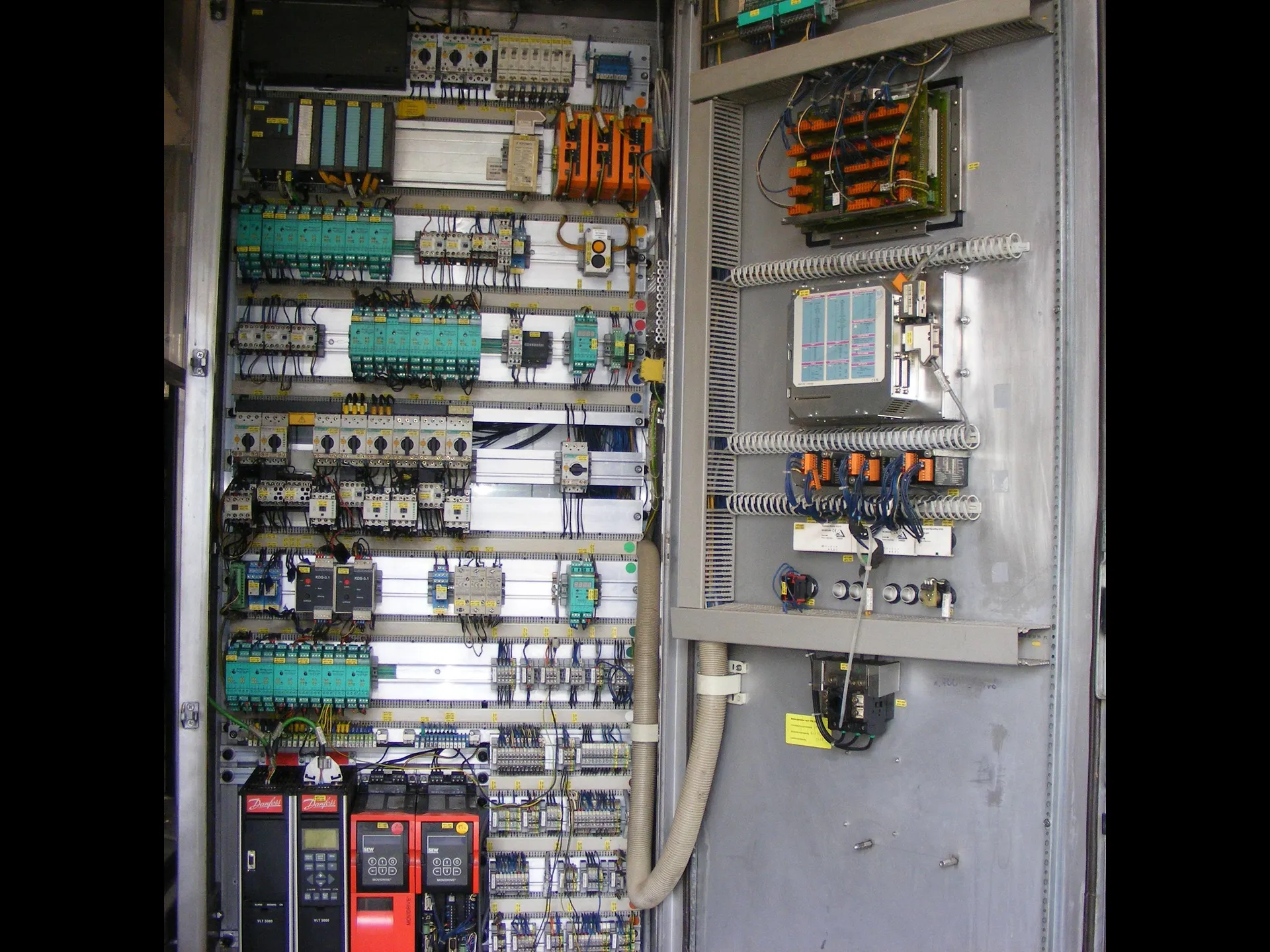

Advanced Automation & Control Systems

- PLC platform: Siemens S7 for process control, diagnostics and integration.

- Signal and I/O: Provision for standard digital signals to synchronize with upstream/downstream equipment on a used bottling line.

- Process control: Counter‑pressure phases managed via PLC for stable fill levels and CO₂ retention.

Production Line Integration Capabilities

- Line compatibility: Ideal for beverage production environments seeking to upgrade or expand a second hand industrial packaging line.

- Upstream equipment: Can interface with external bottle rinsers or blow molding machines (not included).

- Downstream equipment: Compatible with conveyors, labellers, packers and palletizers.

- Handling system: PET neck handling for stable transfer between filler and capper.

Machine Condition & Maintenance History

- Status: In storage; filler dismantled and stored.

- Operating readiness: Operating after scheduled service/maintenance.

- Power: Not connected.

- Operating hours: Not set.

- Typical availability: Unit can be prepared for dispatch after service with a standard lead time.

Operational Performance & Versatility

- Process benefits: Isobaric fixed-valve design supports low-foam filling, minimized oxygen pickup and consistent fill volumes on large PET formats.

- Format range: Optimized for 1.5 L and 3.0 L bottles; additional formats possible subject to parts and changeover kits.

- Closure system: Reliable application of PCO 1881 screw caps for CSD, sparkling water and other carbonated beverages.

Installation Requirements & Site Preparation

- Footprint: 3.8 × 3.2 m; recommended service clearance around perimeter.

- Height: 2.65 m – verify ceiling height and lifting access for installation.

- Utilities (to be confirmed): Electrical supply, compressed air, CO₂ for counter‑pressure, product feed tank and CIP connections as per Krones standards.

- Line layout: Clockwise rotation – plan conveyor routing accordingly.

Safety Standards & Compliance Certification

- Safety features: Perimeter guarding with interlocks and emergency stop circuits integrated via Siemens S7 control.

- Compliance: Designed to meet European machinery safety practices; specific certifications/markings to be verified during inspection and FAT.

This Krones PET Block 54/8 Monobloc Filler–Capper is a robust choice for companies seeking a dependable, second hand solution to enhance beverage production capacity on PET containers within an industrial packaging environment.