Description

Used filling monoblock isobaric Filltec 8000 bph – Overview

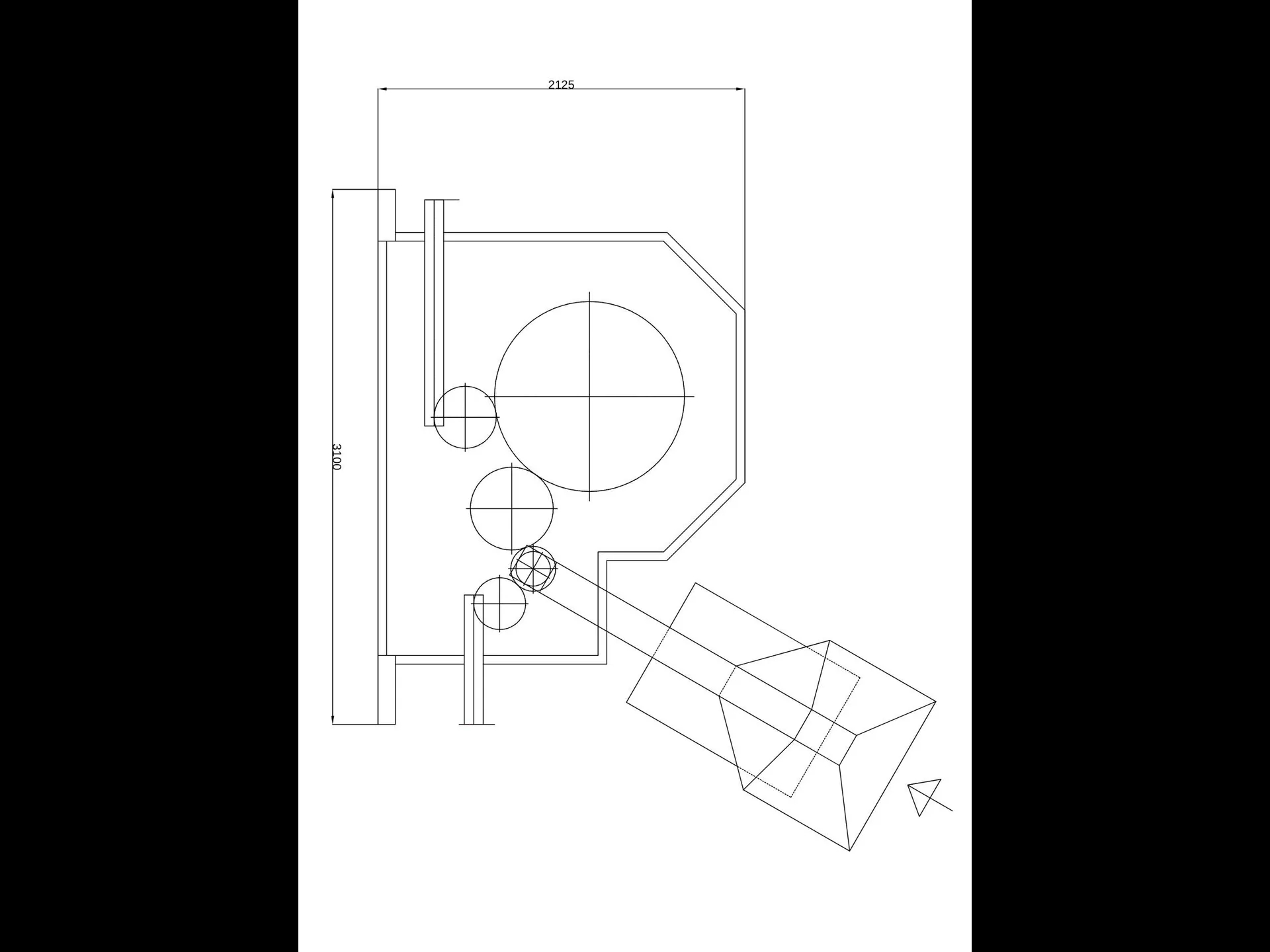

Second hand isobaric filling monoblock Filltec Varifill32/8 (year 2006), complete with AROL crown capper. This pre-owned unit is engineered for beverage production of both carbonated and still products, delivering a nominal speed of 8,000 bottles per hour. With 32 original mechanical filling valves and an 8-head 26 mm aluminum crown capper, it is a robust solution for a used bottling line within modern industrial packaging environments. Rotation direction: clockwise. Ref. no.: M302.

Technical Specifications & Performance Data

Main data

- Manufacturer / Model: Filltec Varifill32/8

- Technology: Isobaric rotary filler with mechanical valves

- Year of manufacture: 2006

- Condition: In production (second hand / pre-owned)

- Nominal speed: 8,000 bph

- Products: Carbonated and still beverages

- Formats processed: 5 formats

- Bottle diameter range: 60–80 mm

- Rotation direction: Clockwise

- Aseptic execution: No (standard isobaric)

- PLC: SIEMENS S7 – 300

Filling and capping groups

- Filler: 32 original mechanical filling valves

- Cap type: 26 mm aluminum crown cap

- Included blocks: Filler + capper (no rinser)

Electrical specifications

- Main supply: 400 V ±5%, 50 Hz ±1%, 3P + N + PE (separate neutral and earth)

- Auxiliaries: 24 VDC

- Instrumentation voltages: 24 VAC – 230 VAC

- Protection rating: IP54 (machine and motors)

Advanced Automation & Control Systems

The monoblock adopts an industrial control architecture based on 24 VDC auxiliaries and segregated power/instrument circuits for stable operation. IP54-rated enclosures and motors support reliable performance in beverage production environments. Interlocked guards and standard safety circuits facilitate compliant operation within a used bottling line.

Process control advantages

- Isobaric filling for consistent product quality on carbonated beverages

- Mechanical filling valves designed for repeatable volumetric accuracy

- AROL capping turret synchronization with filler for secure 26 mm crown cap application

Production Line Integration Capabilities

This monoblock is ready to be integrated into existing second hand or new industrial packaging systems.

Connectivity and interfaces

- Upstream compatibility: infeed conveyors, independent rinsers or blowers (not included)

- Downstream compatibility: conveyors to labellers, inspectors, packers and palletizers

- Format handling: starwheels and guides sized for 60–80 mm bottle diameters across 5 formats

- Utilities: single 400 V 50 Hz power supply with 24 VDC auxiliaries as per specifications

Machine Condition & Maintenance History

- Operational status: In production

- Original equipment: 32 mechanical filling valves retained

- Visual condition consistent with regular operation; detailed maintenance records to be verified during inspection

- Reference number: M302

Operational Performance & Versatility

- Throughput: 8,000 bph nominal on suitable formats

- Product range: carbonated soft drinks, beer, sparkling beverages, and still drinks compatible with isobaric filling

- Capping: 26 mm crown, 8-head AROL turret for high-speed closure integrity

- Changeover: engineered to handle 5 formats within the 60–80 mm bottle diameter envelope

Installation Requirements & Site Preparation

Electrical and environmental conditions

- Power: 400 V ±5%, 50 Hz ±1%, 3P+N+PE

- Auxiliaries / instrumentation: 24 VDC; 24–230 VAC

- Ambient temperature: 5 °C to 40 °C

- Relative humidity: 30%–80% (non-condensing)

- Max installation altitude: 1,000 m a.s.l.

- Hazardous atmospheres: not suitable for explosive or toxic gas environments

Site considerations

- Stable, level floor with adequate drainage and access for cleaning

- Clearances for guarding, conveyors, and changeover activities

- Provision for process media typically associated with isobaric filling (e.g., CO₂ for pressurization) according to the product and plant design

Safety Standards & Compliance Certification

- Ingress protection: IP54 on electrical system and motors for industrial environments

- Low-voltage control circuits: 24 VDC auxiliaries to enhance operator safety

- Mechanical guarding with interlocked doors and emergency stop circuits typical for bottling machinery

- Built to prevailing industrial machinery practices at time of manufacture; compliance documents and risk assessment to be verified during inspection

This Used filling monoblock isobaric Filltec 8000 bph is a proven asset for beverage production, ideal for upgrading or expanding a used bottling line with reliable, high-quality isobaric filling and crown capping within an industrial packaging setup.