Description

Machine Overview

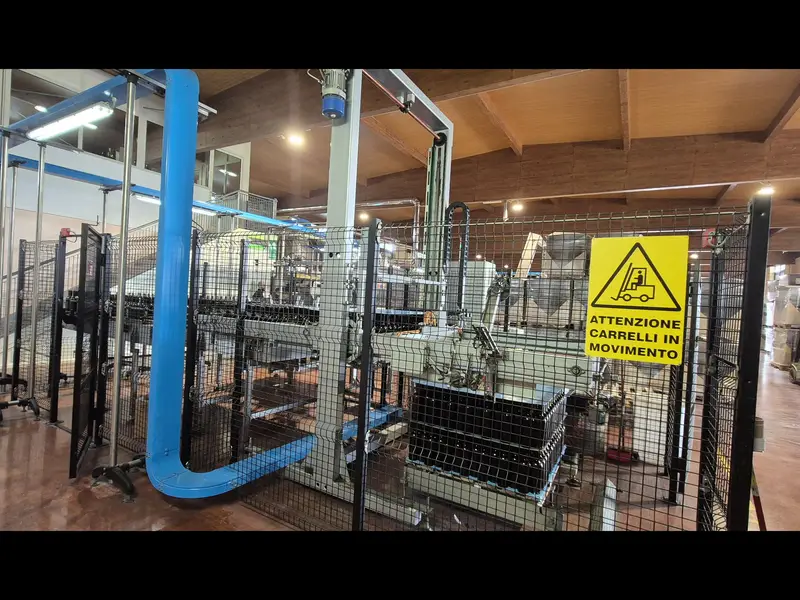

Depalletizer ACMI RASAR D 200 S (year 2007), conventional automatic layer depalletizer with translating twin-clamp system. The first clamp acts as a centering device to stabilize the underlying layer; the second clamp tightens and transfers the full layer onto a polyethylene intermediate plate and then onto the discharge conveyor. Mechanical grippers handle layer pads/interlayers. A column-type layer-pad/top-frame remover with its dedicated magazine is included. Complete with perimeter safety guarding, access doors with interlocks, and photoelectric light curtains. Supplied with empty-pallet stacker/magazine.

Key Technical Data

- Make/Model: ACMI RASAR D 200 S

- Year: 2007

- Operating principle: Top-feed, high-level layer transfer by twin clamps with PE intermediate platform

- Handling type: Conventional (non-robotic)

- Operating mode: Automatic

- Nominal output: up to 20,000 bph (format and layout dependent)

- Containers: Glass and PET bottles, jars, cans, flasks, small pots, etc. (subject to format set-up)

- Unpadding system: Column layer-pad/top-frame remover with magazine (mechanical pick-up of interlayers)

- Pallet management: Empty-pallet stacker/magazine included

- Product feed: From the top

Automation & Control

- Control cabinet with PLC-based logic

- Operator pendant with alarm/event viewer for diagnostics

- Control voltages: auxiliaries 24 VDC; instrumentation 24/230 VAC

- Electrical protection: IP54 cabinet and motors

- Standard I/O for line signals and safety interlocks (details to be aligned during integration)

Line Integration

- Discharge to downstream conveyors at high level via PE intermediate plate and transfer clamps

- Interfaces for pallet infeed, empty-pallet outfeed/stacking, interlayer magazine, and pad/top-frame removal

- Suitable for integration in bottling and canning lines handling a wide range of container formats

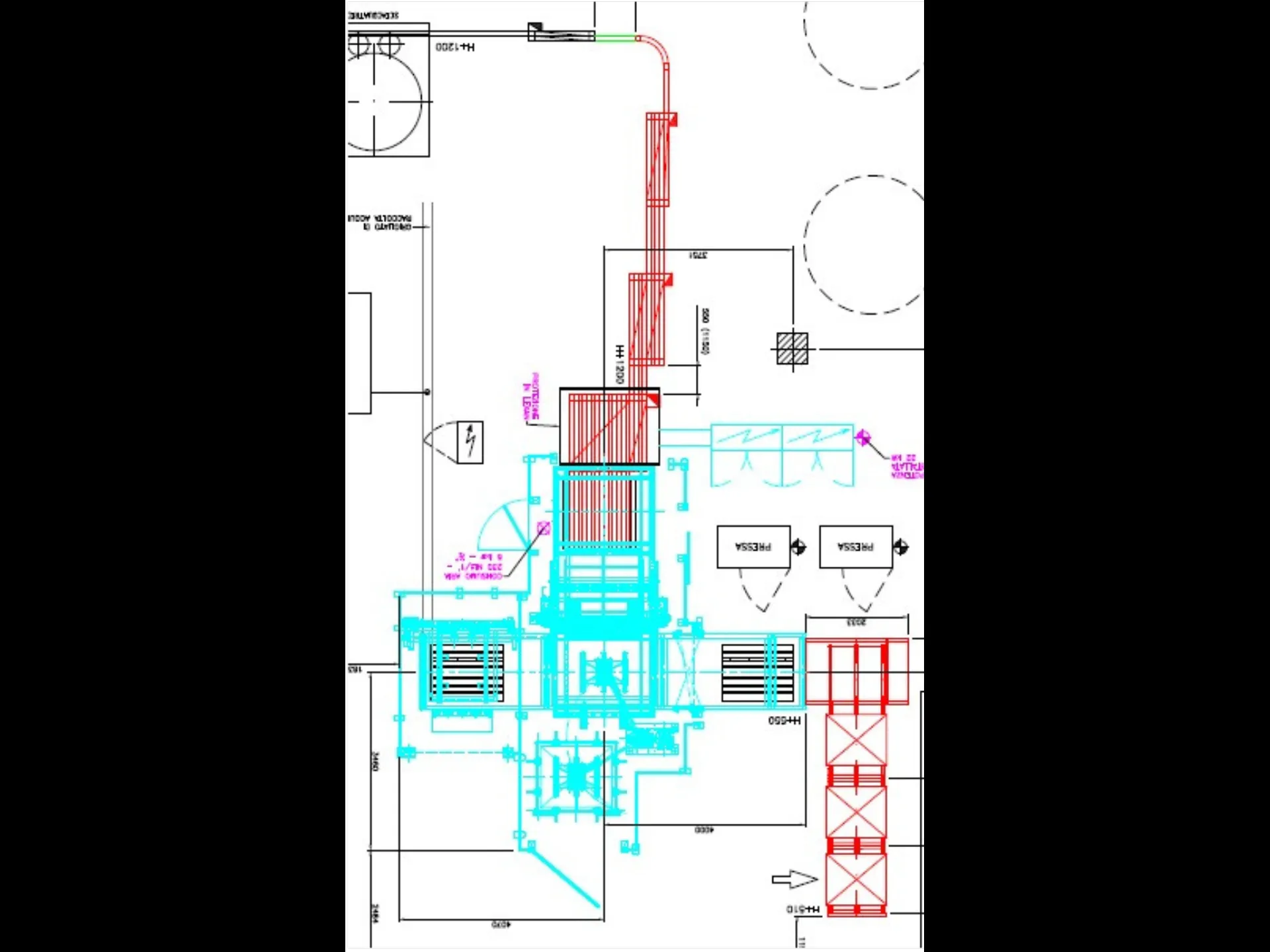

- Layout drawing available; final footprint and interfaces to be confirmed during project engineering

Condition & Maintenance

- Condition: In production

- Routine preventive maintenance recommended: clamp pads, belts/chain tensions, lubrication points, sensor alignment, safety device testing

- Spare parts and format change components to be verified against current installed set

Performance & Versatility

- Up to 20,000 bph depending on container, layer pattern, slip-sheet type, and downstream conditions

- Handles bottles (glass/PET), jars, cans, and similar rigid containers

- Twin-clamp centering ensures layer stability while protecting the layer below

- Mechanical interlayer gripping enables reliable separation of layers and slip-sheets/caps

Site Requirements

- Mains supply: 400 V ±5%, 50 Hz ±1%

- Distribution: 3P + N + PE (separate neutral and earth)

- Auxiliary voltages: 24 VDC; instrumentation 24/230 VAC

- Environmental conditions: 5–40 °C; relative humidity 30–80% non-condensing; max altitude 1000 m

- Area classification: No explosive or harmful gases

Safety & Compliance

- Perimeter guarding with access doors fitted with safety interlocks

- Photoelectric light curtains to prevent access during motion

- Electrical and motor protection degree: IP54