Description

Used UHT Milk Preparation Room Tetra Pak 6600 L/h

Technical Overview of the System

The Used UHT Milk Preparation Room Tetra Pak 6600 L/h provides a complete solution for the aseptic preparation of UHT milk, drinking yoghurt, juices, and flavored beverages. Currently in storage and ready for reinstallation, the system delivers high thermal and microbiological efficiency. Moreover, its modular design allows it to operate at 2640 L/h, 3850 L/h, and up to 6600 L/h in full configuration. Therefore, it adapts well to varying production demands.

Homogenization Section

At the core of the Used UHT Milk Preparation Room Tetra Pak 6600 L/h lies a Tetra Pak homogenizer, model Tetra Alex, which ensures effective fat globule size reduction and consistent product texture. As a result, it stabilizes complex emulsions such as flavored milk or drinking yoghurt and prevents phase separation during storage. Importantly, this homogenizer is non-aseptic and operates upstream of the UHT sterilization process, which eliminates any microbial load introduced during homogenization. Furthermore, the homogenizer supports high working pressures and simplifies maintenance. In addition, the robust construction ensures long-term reliability.

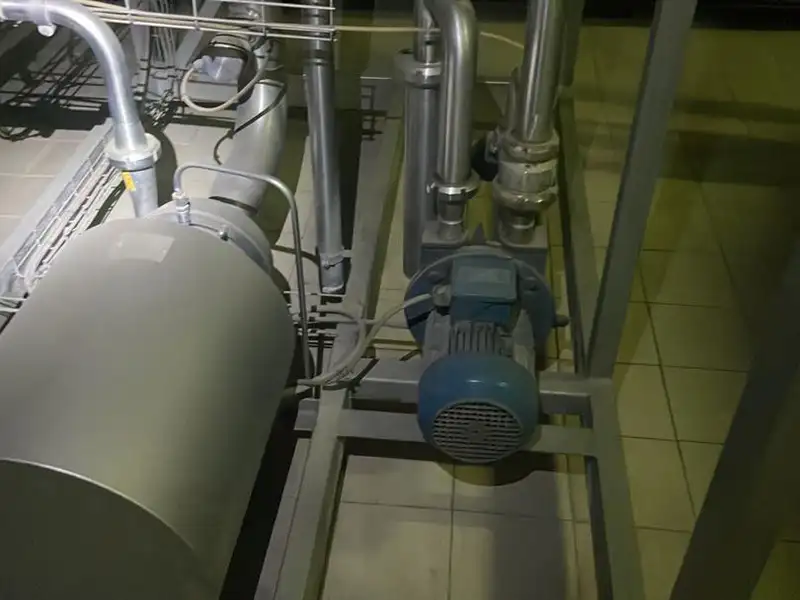

Integrated Deaeration System

The system includes a Tetra Pak deaerator (2005) equipped with an auxiliary pump and tank. Specifically, this component removes dissolved oxygen and unwanted gases from the product before thermal processing. Consequently, it improves product stability and reduces oxidation. Additionally, the vertical configuration ensures efficient gas separation. Meanwhile, the design minimizes product loss and guarantees a continuous flow to the next stage.

High-Performance Tubular UHT Module

Thermal sterilization occurs through a tubular UHT heat exchanger, manufactured by Tetra Pak and model Tetra Therm Aseptic. In particular, this component sterilizes products via indirect heat exchange while preserving organoleptic properties. Importantly, the module includes a holding coil to maintain temperature over a defined time span. Thus, it complies with food safety regulations and ensures microbiological safety. Similarly, its modular design allows for easy integration into existing lines.

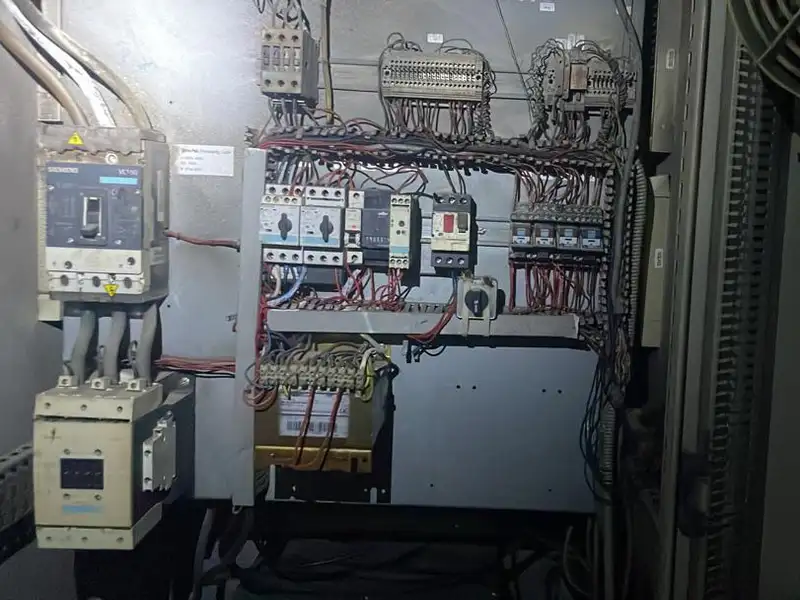

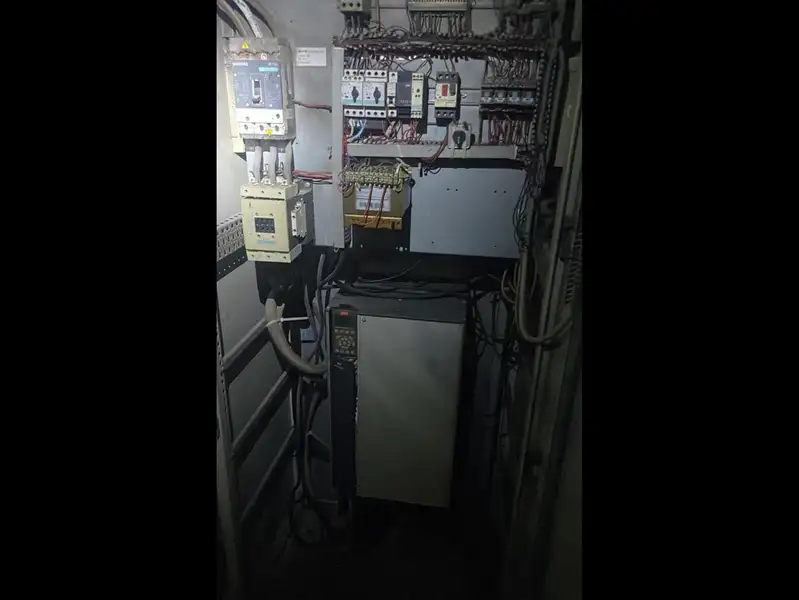

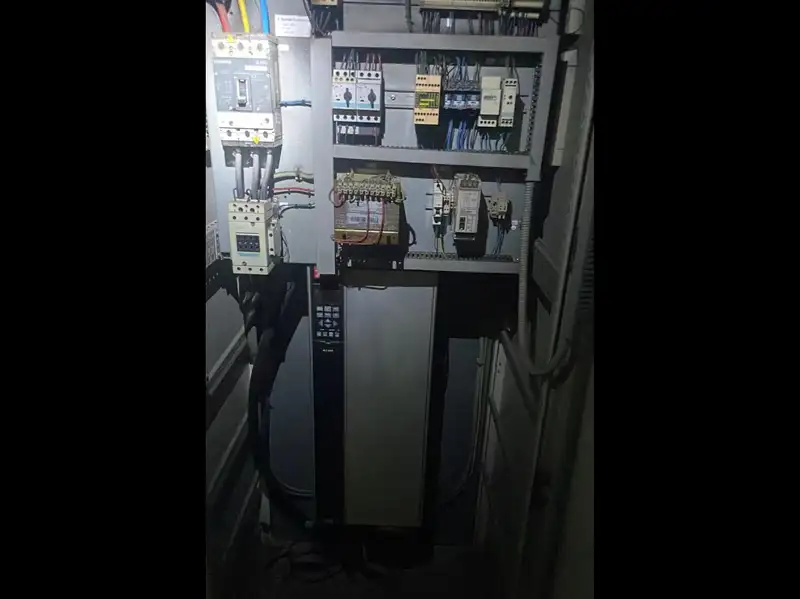

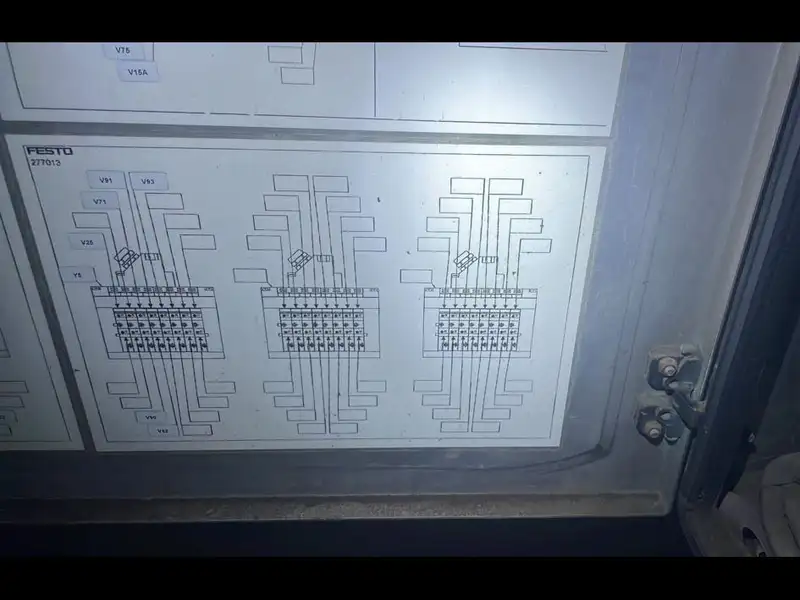

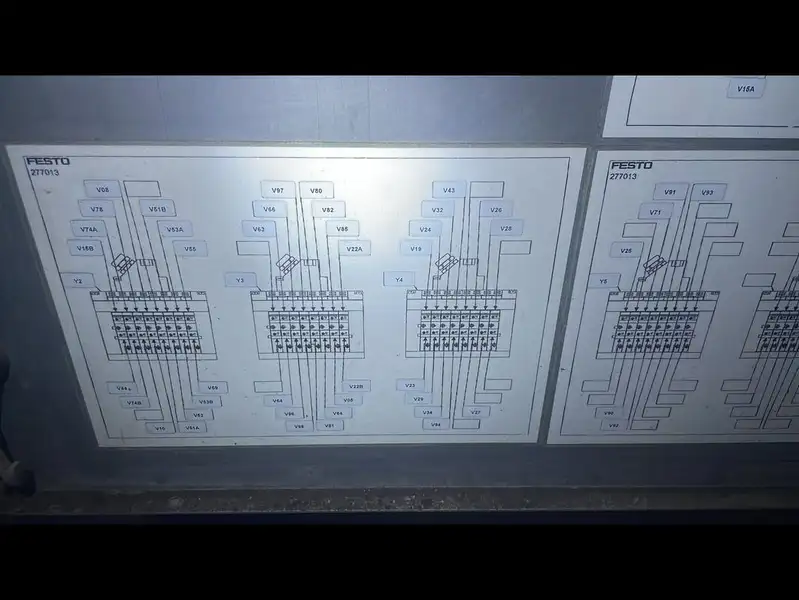

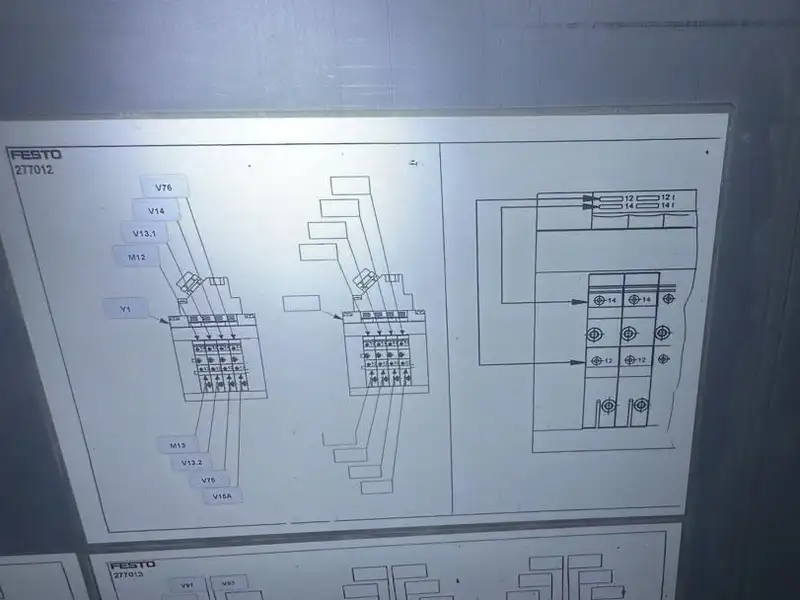

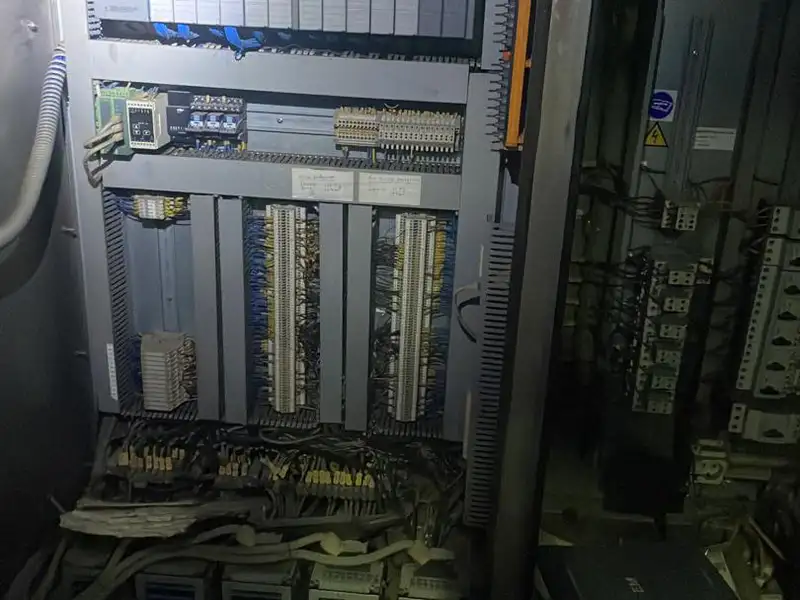

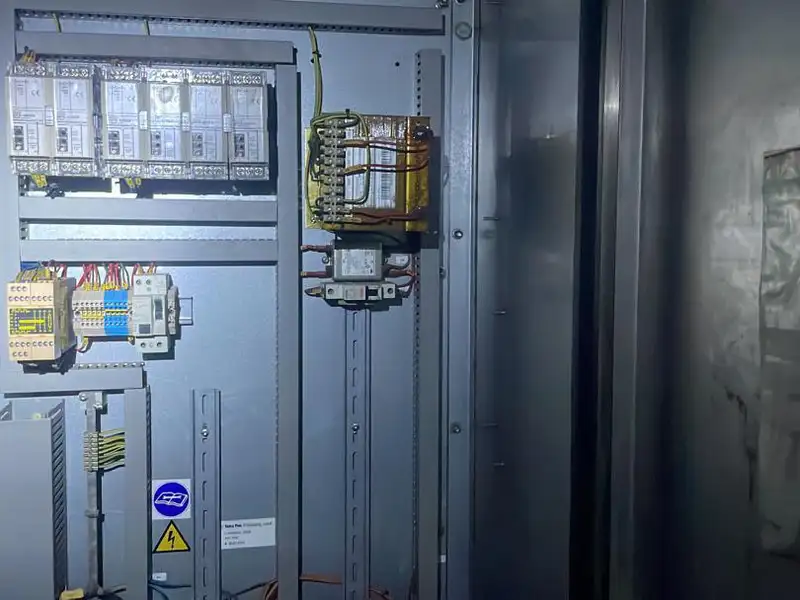

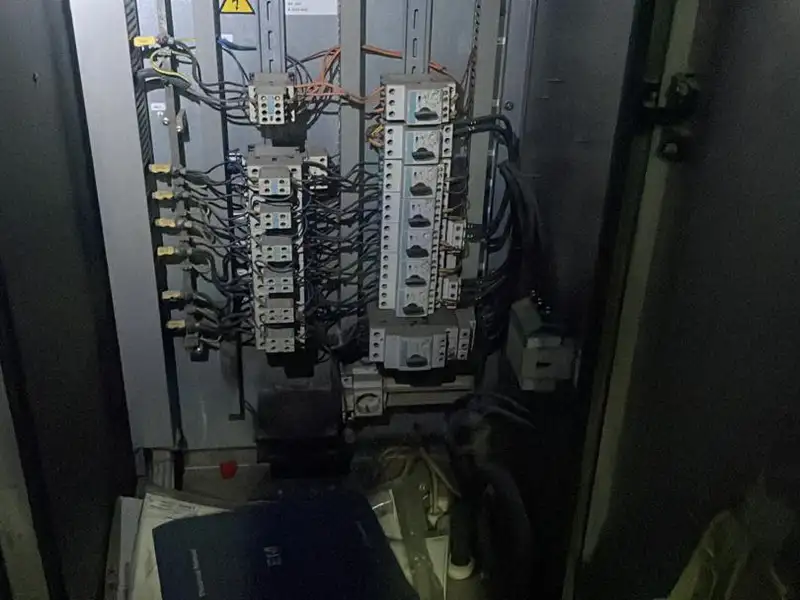

Electronic Control and Automation

The line features an electrical control panel, a Siemens PLC, and operator panels for precise management of each phase. Notably, it includes detailed electrical schematics, Festo pneumatic valves, and Danfoss inverters to dynamically control pumps and heat exchangers. As such, the automation enables continuous processing. Besides, it optimizes the CIP cycles, reduces downtime, and enhances traceability. Above all, it ensures reliable performance across diverse operating conditions.

Conclusion

In summary, the Used UHT Milk Preparation Room Tetra Pak 6600 L/h offers a complete, high-efficiency system for preparing UHT milk and beverages. Thanks to its top-tier components and scalable design, this line stands as an ideal choice for dairy producers. Whether the goal is reliability, hygiene, or adaptability, this solution meets strict industry standards. Finally, the system remains in storage and is available for immediate installation.