Description

Used Bottling Lines for edible oil 6000 bph

General Configuration of the Bottling Line

The Used Bottling Lines for edible oil 6000 bph line processes edible oil in 1-liter PET bottles, operating at a nominal speed of 6000 bottles per hour. The configuration includes equipment from multiple manufacturers, integrated to ensure continuous operation and reliability in filling, labeling, packaging, and palletizing. Operators correctly shut down the entire system in December 2022. At present, the machines are dismantled and stored in suitable conditions. Consequently, this line is immediately available for relocation and reuse. Overall, the structure represents a compact yet complete solution for medium-scale production.

Container Formation: KOSME Blow Molding Machines

The Used Bottling Lines for edible oil 6000 bph line includes two blow molding machines from KOSME, model KSB3000, year 2001. Each unit works with a preform box and an automatic transport system that feeds the blower. As a result, the system supports on-site bottle production. Therefore, it reduces logistics costs and improves plastic material handling. In addition, the dual-machine setup enhances production continuity and minimizes downtime.

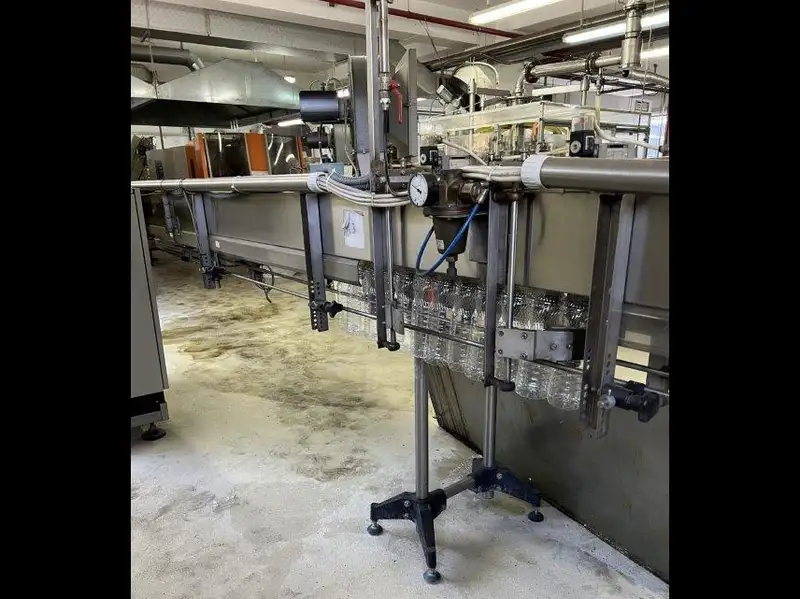

Cooling System: MTA Chiller and Air Conveyors

An MTA chiller, model TAE 051, year 2000, cools the molds in the blow molding machines. Moreover, KOSME air conveyors, model L2000, year 1999, made of AISI 304 stainless steel, transfer the blown bottles to the filling monoblock. Notably, the system includes electrical cabinets with integrated PLCs and built-in air filters. Thus, it ensures effective airflow control and maintains consistent air quality. From a technical standpoint, this contributes to long-term reliability and hygienic conditions.

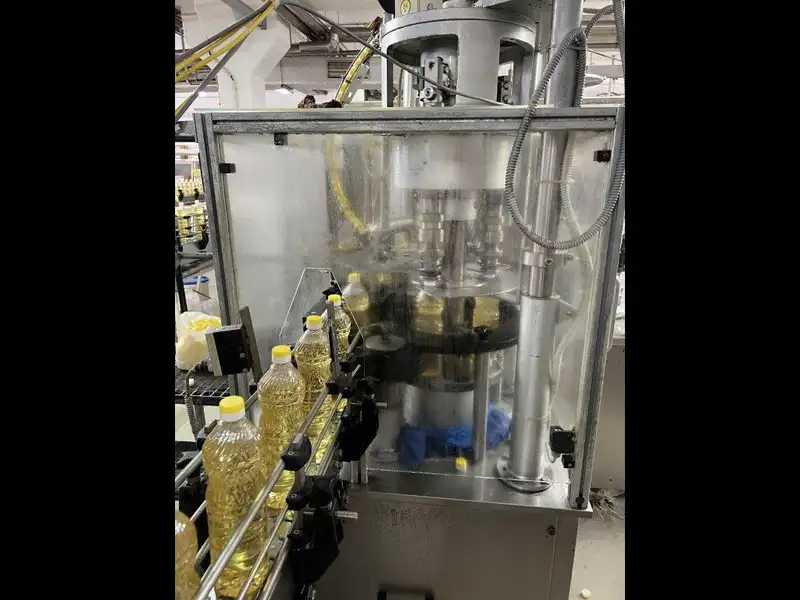

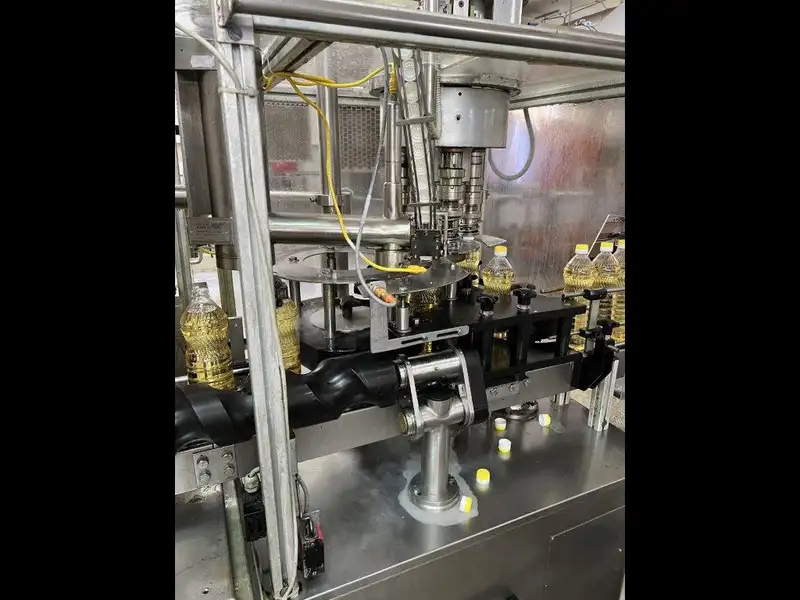

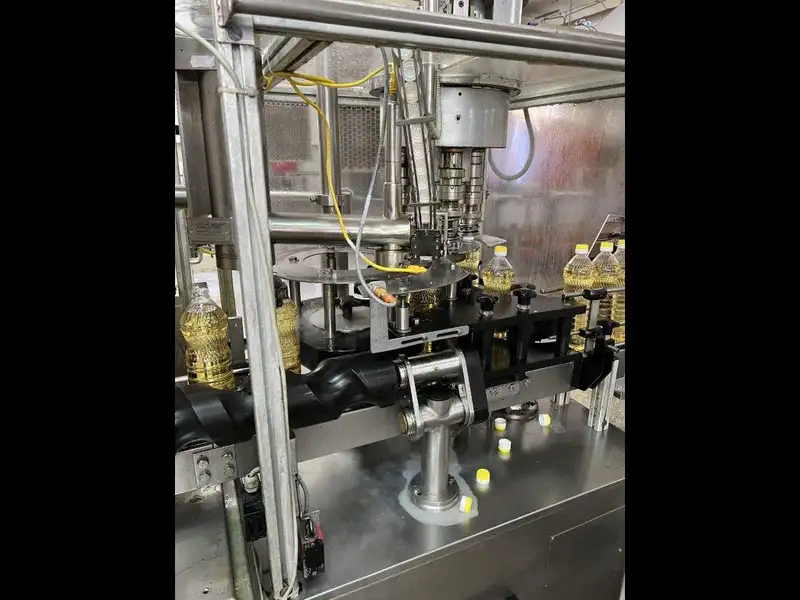

Filling Monoblock: ICS RVP-12/ZS-3N

The ICS filling monoblock, model RVP-12/ZS-3N, year 1995, serves as the core of the Used Bottling Lines for edible oil 6000 bph. This machine doses edible oil with precision, ensuring product integrity and consistent fill volumes. Furthermore, the system synchronizes with upstream and downstream units. Consequently, it enables stable operation even under variable load conditions. Likewise, its mechanical construction supports easy maintenance and spare part replacement.

Labeling Machine: ICS with Cold Glue

An ICS labeling machine, model ERG-6/2/2, year 1995, applies paper labels using cold glue. Specifically, the machine ensures proper adhesion on PET containers. Additionally, it supports the 1-liter format used throughout the line. In practice, this technology remains widely adopted for edible oil packaging. Therefore, the labeling unit integrates efficiently into the overall production layout. To sum up, it provides a cost-effective solution without compromising performance.

Internal Handling and Packaging

ICS conveyor belts, installed in 1995, connect all key stations. Subsequently, the line transitions to the packaging phase. It includes an ICS case packer, model Vlaga 2IC, which arranges bottles in transport boxes with a 3×5 layout. At the same time, a shrink wrapper from SMIPACK, model BP802ARV 280R-SP, year 2013, wraps bottles in film with a 2×5 configuration. Accordingly, the dual packaging options provide flexibility based on market or client needs. Overall, these systems enhance the final presentation and transport efficiency.

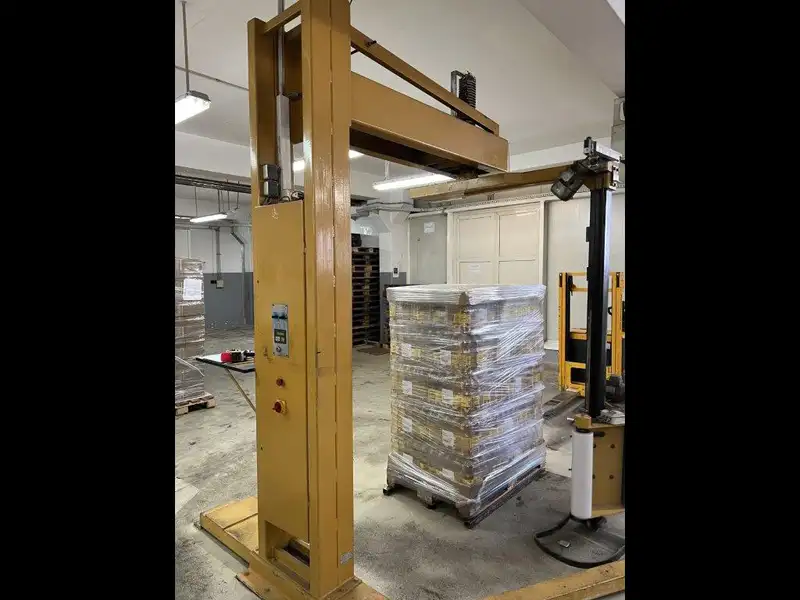

Palletizing and Installed Power

A ZLATOROG pallet wrapper, model OP161, year 1999, manages end-of-line palletizing operations. In terms of power, the complete Used Bottling Lines for edible oil 6000 bph system requires 495 kW of installed power, including equipment, compressors, and chillers. For this reason, operators must evaluate electrical infrastructure compatibility before reinstallation. In conclusion, this line offers a comprehensive, ready-to-use solution for edible oil bottling, from container production to palletized output.