Description

Used complete isobaric bottling line for CSD 6400 bph

Technical Overview of the Line

This Used complete isobaric bottling line for CSD 6400 bph produces carbonated soft drinks with a nominal output of 6400 bottles per hour. Specifically, the line handles 0.50-liter PET containers using an isobaric filling system. In particular, this technology maintains constant internal pressure during the filling process. As a result, it prevents carbon dioxide loss and ensures that the final product preserves its quality and carbonation from tank to cap.

Container Compatibility and Specifications

The line supports PET bottles with 18-10 and 18-81 PCO necks, which represent standard formats across the beverage industry. Consequently, operators can integrate the system into existing lines without modifying downstream capping equipment. In addition, this compatibility facilitates bottle sourcing and packaging flexibility. Furthermore, the system ensures that transitions between production batches remain smooth and efficient.

Working Hours and Line Condition

The machines in this Used complete isobaric bottling line for CSD 6400 bph have completed only 3000 hours of operation. In comparison to similar used systems, this relatively low usage indicates limited wear on mechanical parts. Therefore, technicians can expect a good performance with minimal maintenance needs. Moreover, this condition makes the line suitable for facilities that require immediate deployment with limited downtime.

Line Composition

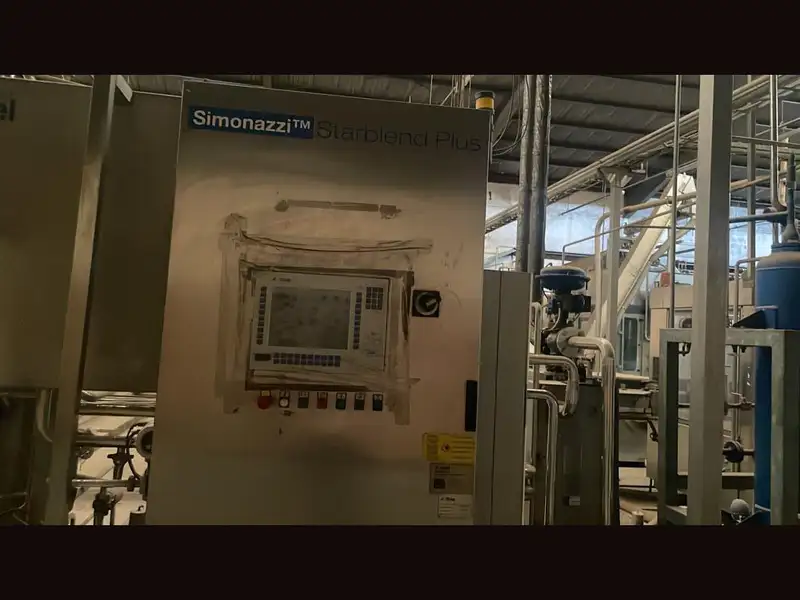

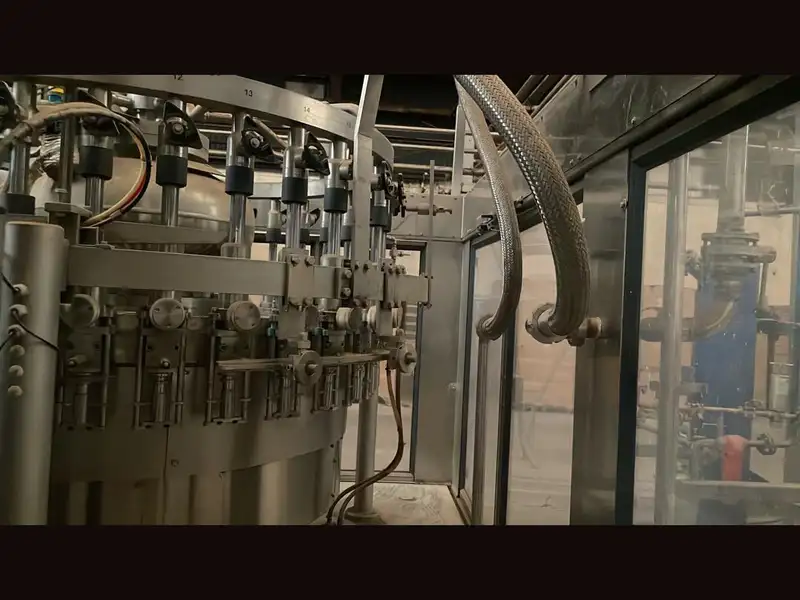

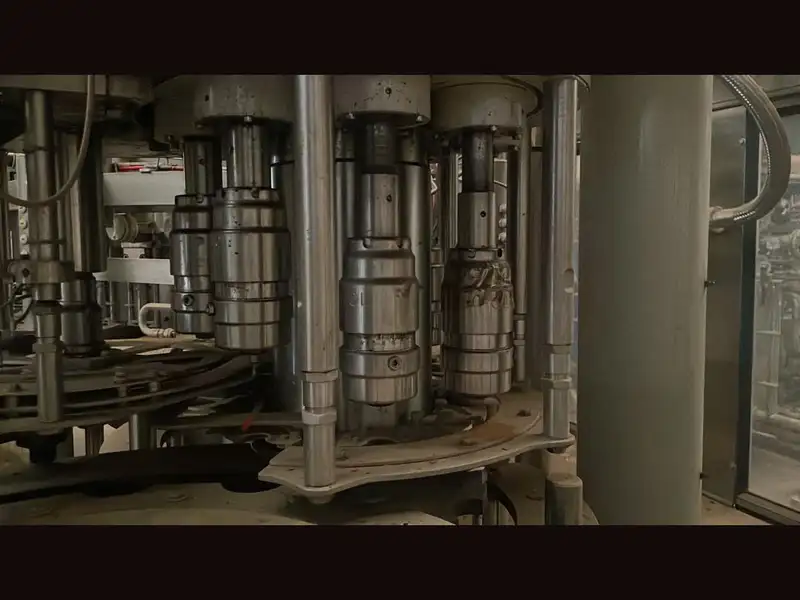

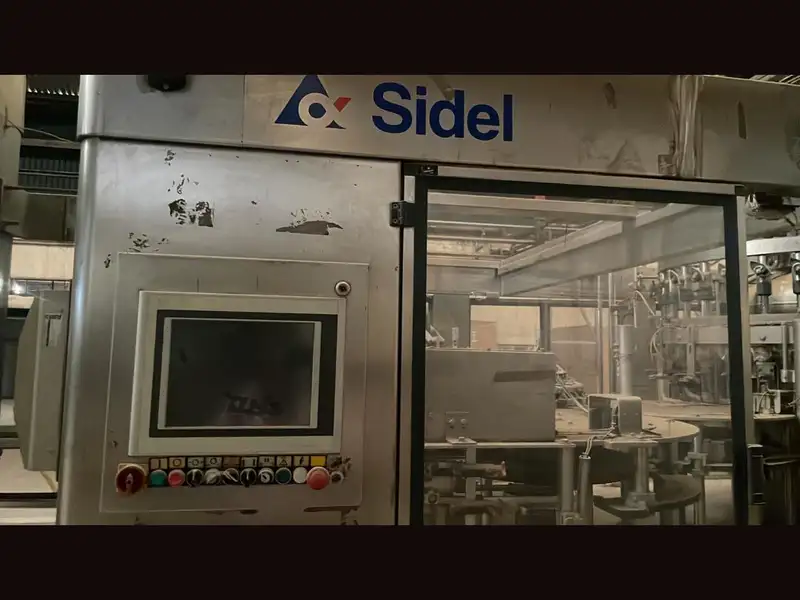

The process begins with a Sidel SBO4 COMPACT blow molding machine, built in 2006, which forms PET bottles directly from preforms. Then, the Simonazzi-Sidel Starblend mixer, manufactured in 2007 blends water, syrup, and carbon dioxide under pressure. Afterward, the product is managed in the Simonazzi-Sidel Bluestar filling monoblock, also from 2007. This unit includes 32 grippers, 32 isobaric filling valves, and 8 capping heads. Thanks to this configuration, the line fills and caps each bottle quickly while maintaining product integrity.

Additionally, the machine layout allows for optimal integration of automation and operator access. Notably, each module connects via pre-aligned interfaces, which streamline installation and minimize commissioning time. Altogether, these features contribute to high production efficiency and ease of maintenance.

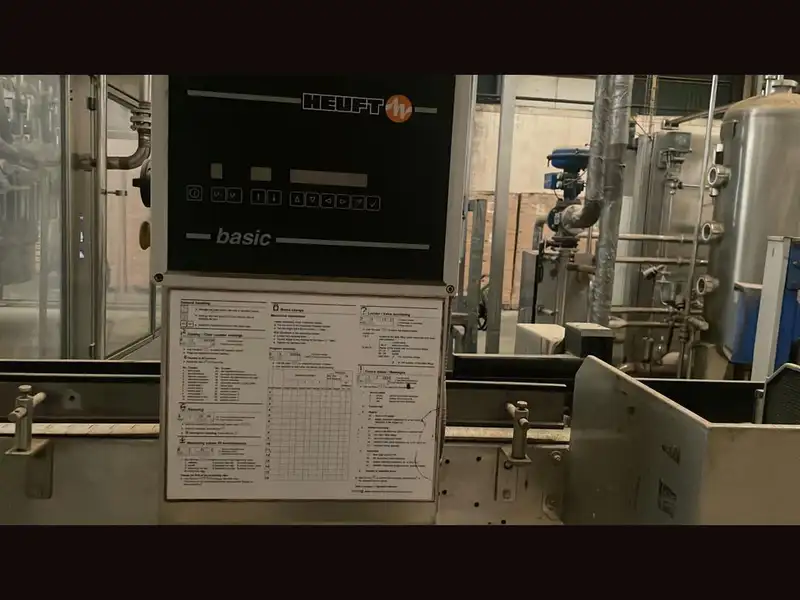

Quality Control and End of this Used complete isobaric bottling line

To guarantee packaging integrity, the line includes a Heuft inspection unit that checks bottle necks and caps for defects. Following inspection, the bottles pass through a Sidel RollQUATTRO F15 labeling machine (2007), which applies wrap-around labels at high speed with precision. Subsequently, a Cermex CP 18 AAE shrink wrapper (2006) packages bottles into multipacks using shrink film. Throughout the process, Sidel conveyors transfer bottles between stations without creating friction points or mechanical delays.

Moreover, the conveyor system provides buffer capacity where necessary, thereby reducing the risk of line stoppages. In turn, this helps operators maintain consistent output even during temporary slowdowns or changeovers.

Safety and Compliance of this Used complete isobaric bottling line

The manufacturer equipped this Used complete isobaric bottling line for CSD 6400 bph with multiple active safety systems, including physical guards, interlocked access panels, and emergency stop devices. Above all, the system complies fully with European CE standards, which regulate operator safety and equipment reliability. Therefore, companies that prioritize regulatory compliance and workplace safety will find this line especially suitable.

Furthermore, the design allows for easy access during cleaning and maintenance, which enhances operational safety even during non-production phases. As a result, the line minimizes both risk and downtime across the entire bottling cycle.