Description

Used revised Electronic SERAC Filling Monoblock for Milk and Drinking Yogurt 7000 bph

Overview of the Used Electronic SERAC Filling Monoblock

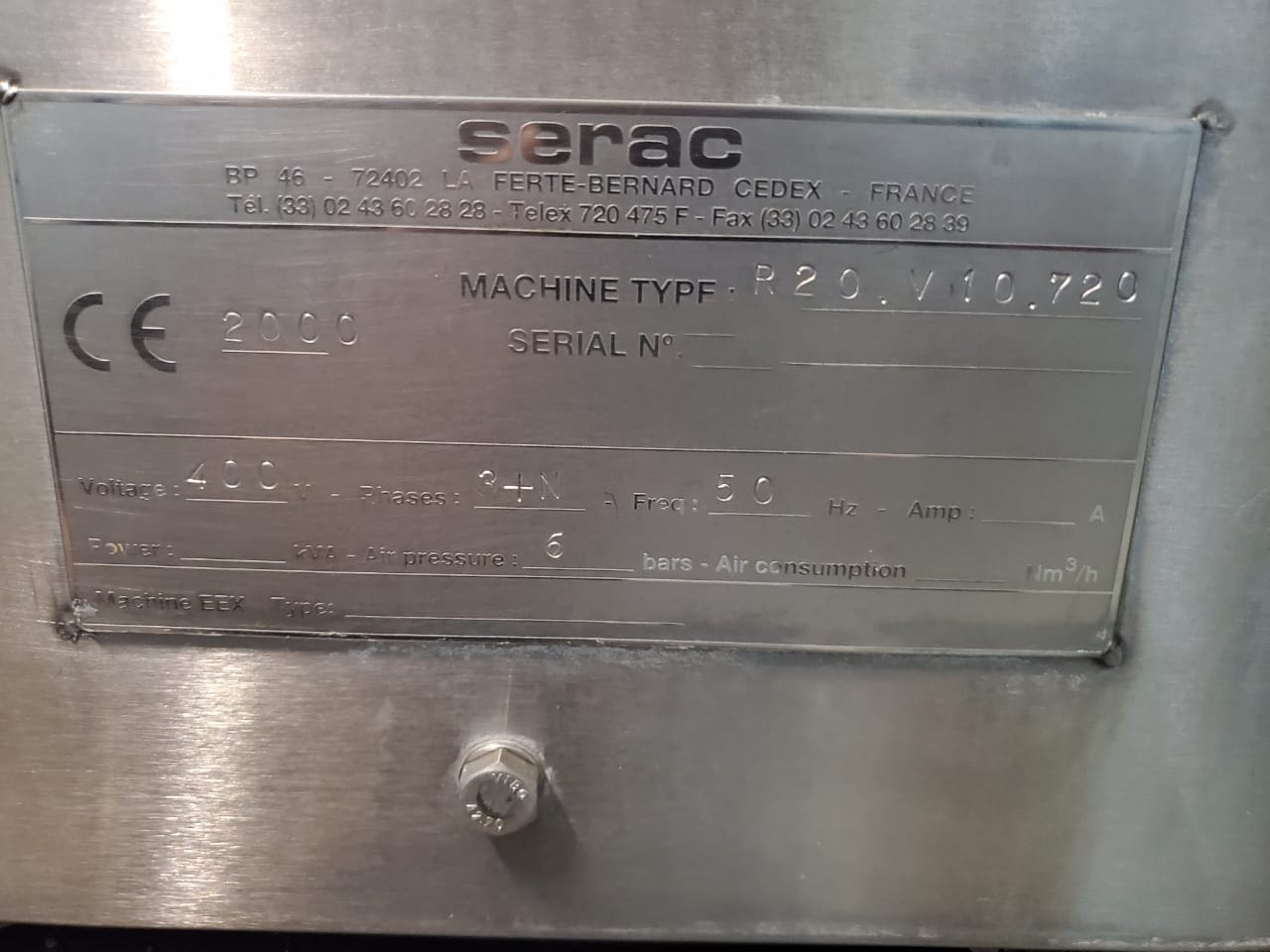

The SERAC R20.V10.720 electronic filling monoblock fills fresh milk and drinking yogurt under ESL (Extended Shelf Life) conditions. The Used revised Electronic SERAC Filling Monoblock for Milk and Drinking Yogurt 7000 bph optimizes the hygienic process to guarantee a product shelf life of up to 19 days by maintaining a controlled environment and ensuring precise dosing. Consequently, it minimizes contamination risks and enhances product consistency.

Technical Specifications

Manufactured in 2000, the Used revised Electronic SERAC Filling Monoblock for Milk and Drinking Yogurt 4000 bph remains in storage and utilizes a weight-based filling system with high-precision electronic scales. As a result, the weighing system delivers accurate dosing, minimizes waste and product loss, and maintains the quality standards required by the dairy industry.

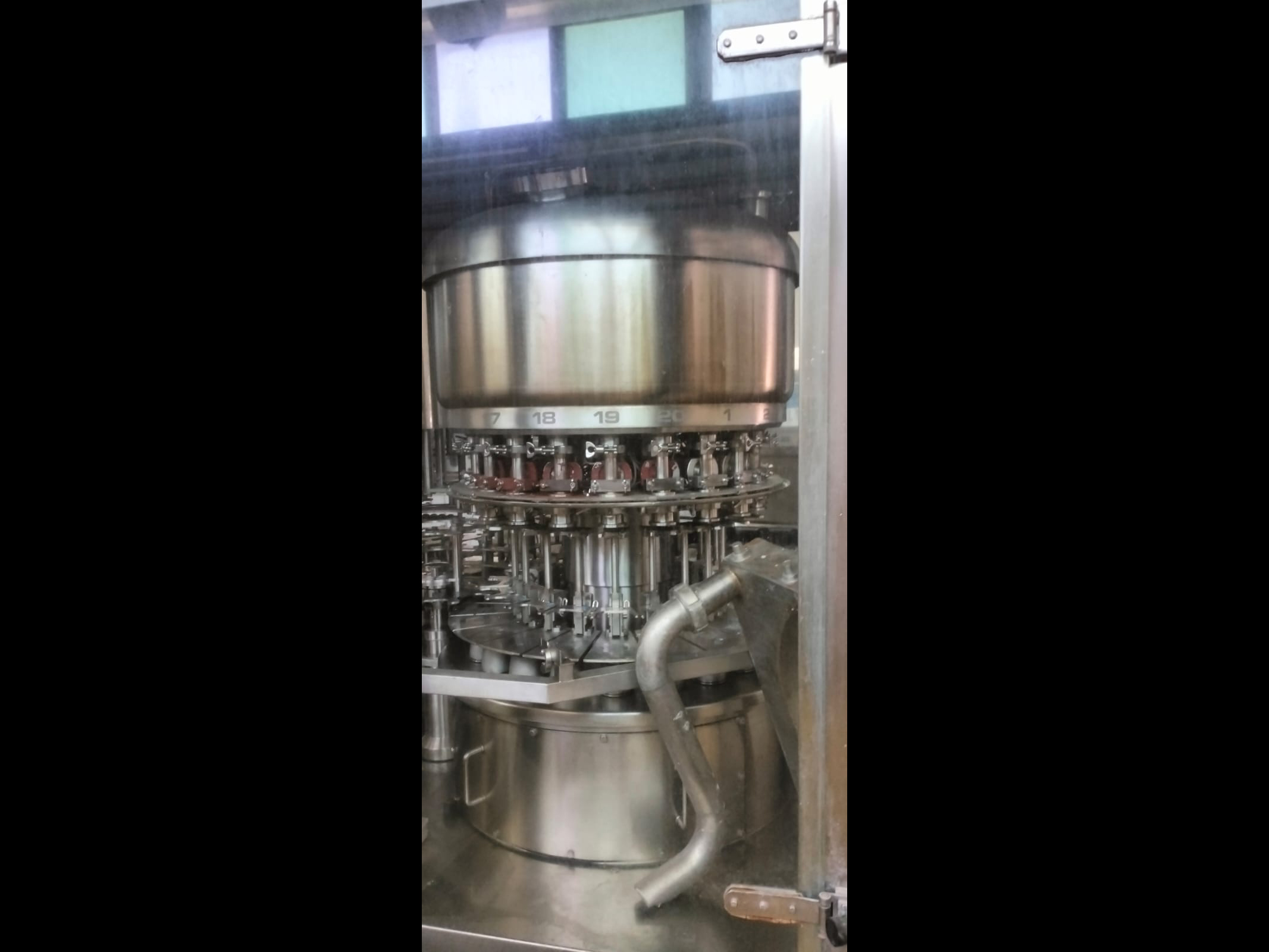

Furthermore, the monoblock rotates clockwise, optimizing production flow and integration with other line equipment. The filling module includes 20 filling valves, which ensures high operational efficiency and a continuous production flow. Additionally, the capping section features 8 capping heads, which apply a 38 mm plastic screw cap, compatible with the 38 mm neck type.

Production Capacity and Efficiency of Used Electronic Filling Monoblock for drinking yogurt 7000 bph

Moreover, the system produces 4000 bottles per hour (bph), making it ideal for medium-to-high capacity plants that require high precision and reliability. The 38 mm plastic cap meets dairy industry standards, ensuring a secure and airtight closure that, in turn, preserves the product’s organoleptic characteristics over time.

Safety and Durability

From a safety perspective, the SERAC R20.V10.720 monoblock includes advanced protective devices that reduce contamination risks and enhance operator safety. In addition, its robust structure and high-quality materials provide long operational durability, reduce maintenance needs, and offer high wear resistance. Consequently, this makes it a highly reliable choice for industrial applications.

Electronic Monitoring and ESL Technology

Likewise, the machine’s electronic architecture continuously monitors the process and allows parameter adjustments to adapt to different product viscosities and production variations. Thanks to this capability, manufacturers can maintain optimal efficiency. The integrated ESL system of the Used revised Electronic Filling Monoblock for drinking yogurt 7000 bph not only minimizes contamination risks but also reduces the need for invasive thermal treatments, thereby preserving the quality of milk and drinking yogurt.

Conclusion of the Used Electronic SERAC Filling Monoblock

Given its advanced technical features, the Used Electronic SERAC Filling Monoblock for milk offers a highly specialized solution for dairy manufacturers seeking a reliable, precise, and efficient filling system. Furthermore, the combination of weight-based filling technology, automatic capping, and advanced electronic management ensures a high-quality product that meets industry standards. As a result, companies can achieve consistent production performance.

Moreover, the SERAC electronic filling monoblock helps dairy companies optimize their production process, reduce waste, and extend the shelf life of milk and drinking yogurt while maintaining high safety and hygiene levels in the packaging process. Consequently, this leads to improved productivity, reduced operational costs, and enhanced product quality.