Description

Used Bottling Line KRONES with Aseptic Filling 36000 bph

The used KRONES bottling line with aseptic filling 36000 bph provides a highly efficient solution for the beverage and dairy industries, meeting productivity and quality demands in high-capacity production environments. This system ensures the highest standard of sterilization, preserving the organoleptic properties and food safety of the bottled product. Furthermore, it is designed to offer consistent performance throughout long production runs.

The process combines Blow-Fill-Seal (BFS) and wet aseptic technology, ensuring full aseptic integrity throughout the production flow.

Line Speed and Capacity

The Used aseptic line KRONES processes 36000 bottles per hour (bph), on the format 500 ml, making it suitable for high-capacity production. It handles PET containers and supports various formats, including 0.3 L, 0.4 L, 0.5 L, and 1.0 L. Moreover, the system can adapt from 250 ml up to 1.5 L bottles, offering a broad production flexibility. In addition, this versatility makes the line ideal for different applications in the beverage industry, including milk, juices, tea, and flavored water. As a result, the line adapts easily to various markets and production demands by configuring different container sizes. Therefore, it offers flexibility for a range of product types.

Aseptic Filling Technology in the Used aseptic line KRONES

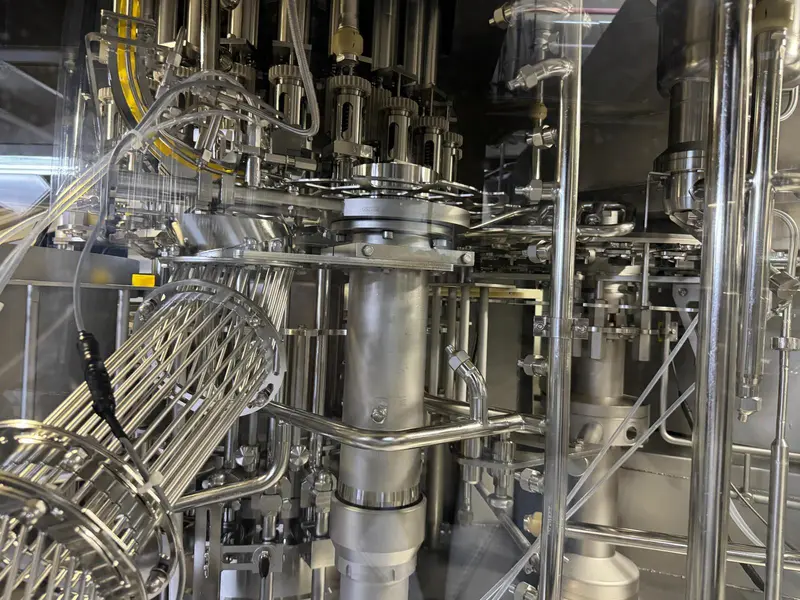

The line’s aseptic filling system eliminates microbiological contamination. Moreover, the sterilization and filling processes occur while keeping the product sealed in aseptic conditions, minimizing preservatives and ensuring a long shelf life without refrigeration. This process is critical for handling sensitive products like milk and fruit juices, which require advanced sterilization to maintain their nutrients and natural properties. Consequently, the line ensures that all products meet stringent quality and safety standards.

The aseptic filling technology includes electronic volumetric filling valves with an accuracy of ±0.3%, supporting both cold filling at 20 °C and ambient temperature filling.

The system uses a wet sterilization method with peracetic acid (PAA) or hydrogen peroxide, achieving contact times of less than 8 seconds and leaving residuals below 0.1 ppm.

Additionally, the filling environment is maintained at ISO Class 5 cleanliness, using HEPA filtration and positive pressure control, ensuring the highest standards of contamination prevention.

Key Components of the Line

The system manages sterilization with a STORK machine, available in two units. In addition, the system also handles product homogenization with a STORK homogenizer (available in two units). These devices ensure consistent product quality, especially for beverages like milk and juices. As a result, the system achieves uniformity in the final product, improving consumer satisfaction.

The UHT system (Ultra High Temperature) uses the VarioDose Krones to treat the product at high temperatures, eliminating bacteria and microorganisms without compromising quality. Along with the system, Jongia 2010 tanks and APV 2011 tanks are used, both designed for aseptic operation, and CIP APV 2010 provides in-situ cleaning. Thus, the line ensures complete hygiene during the entire filling process.

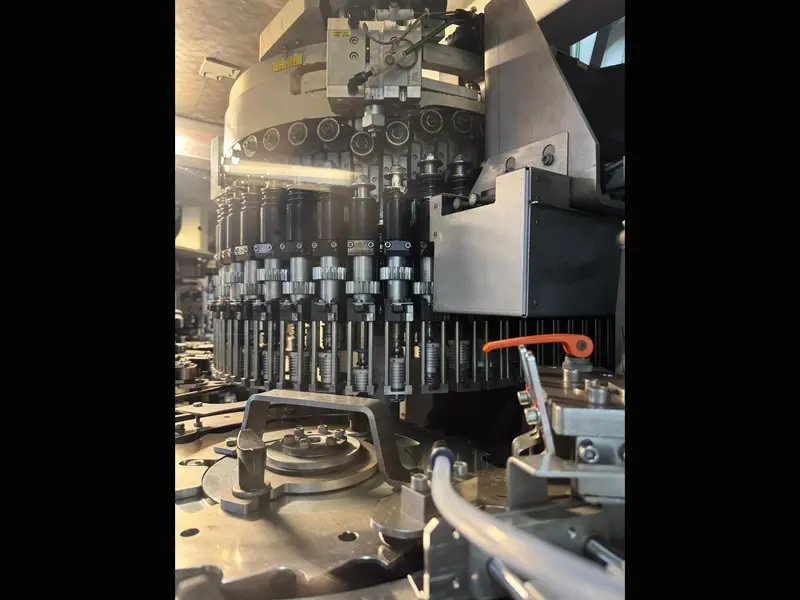

The filling process uses a Krones monoblock from 2010 to manage aseptic filling and sealing of bottles. Additionally, the CIP Krones VarioClean 2010 cleans the filler system effectively, reducing contamination risks and improving operational efficiency. In turn, this boosts the overall productivity of the line.

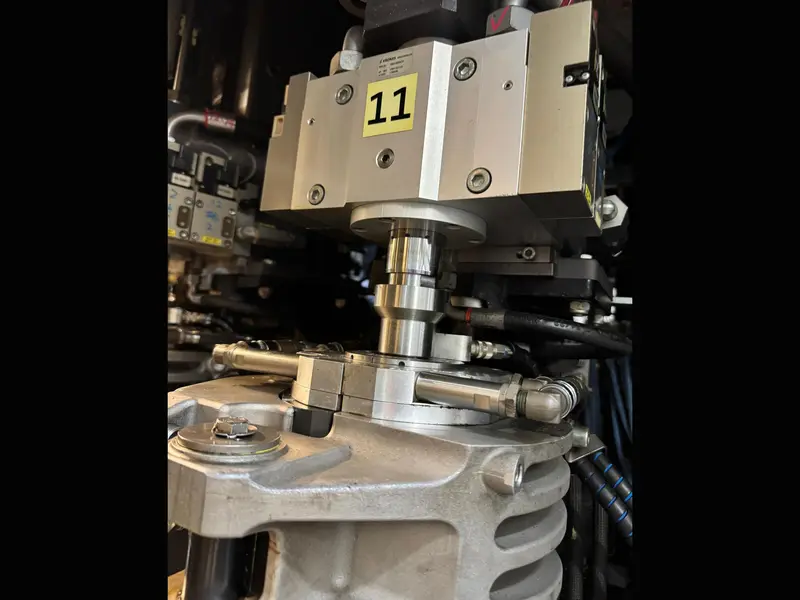

The blow molding section utilizes a Krones Contiform S20 machine capable of processing up to 42,000 preforms per hour, with sterile air protection during the blowing phase to prevent contamination.

Bottle capping is executed with magnetic torque-controlled cappers, achieving a leakage rate of less than 0.01%, fully compliant with FDA 21 CFR 113 standards.

Other Devices and Features

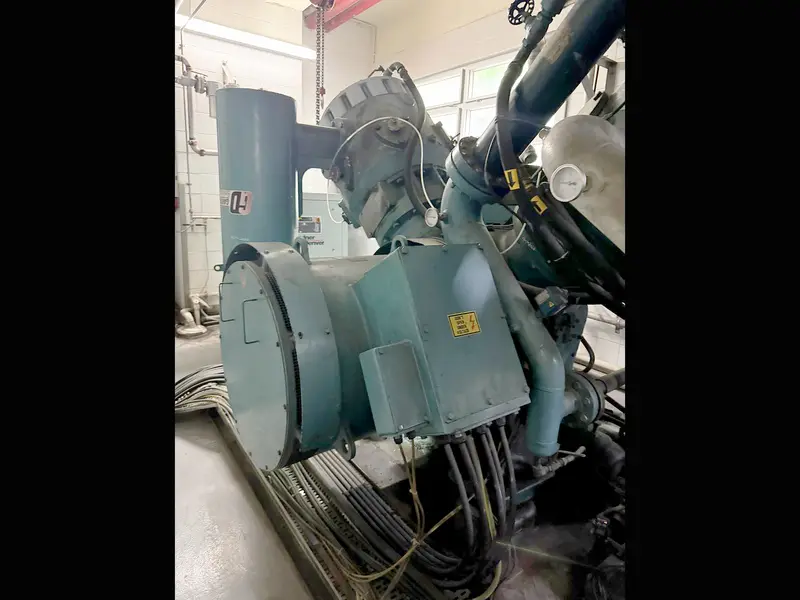

The line includes numerous essential components, such as a 10 bar Atlas Copco compressor, a 2010 Atlas Copco chiller for cooling, and a Krones Contiform S20 blow molding machine from 2010, which produces PET containers. In particular, the inspection system uses a Krones Checkmat 2010 to ensure accurate inspection of bottles during filling and capping. Therefore, the system provides real-time quality assurance to maintain product standards.

The VIDEOJET printer codes bottles, while the Jinhong Sleeve ST2 labeling machine from 2017 applies labels quickly and accurately. Subsequently, the final packaging stage uses a 2010 Case Packer and a 2010 Fuji Yusoki Kogyo palletizer, ensuring automatic packaging and palletizing of finished products. Thus, the line guarantees efficient and reliable packing processes.

A laminar flow hood covers the conveyor belt section, keeping bottles in a sterile environment until labeling is completed, ensuring no secondary contamination.

The Krones LDS controlling system monitors critical parameters in real time, such as peracetic acid concentration, filling temperatures, and environmental particle counts, enhancing process stability and product safety.

Line Condition and Timelines

The used KRONES bottling line with aseptic filling 36000 bph remains in good working condition and will be available for dismantling starting from April 2025. Therefore, its optimal operating condition makes it a reliable choice for companies seeking high-capacity and high-quality solutions for producing long-life beverages. As a result, companies can benefit from this line’s continued performance.

Conclusion of the Used aseptic line KRONES

This Used aseptic line KRONES offers a highly reliable technical solution for aseptic beverage production. With its aseptic filling technology and high-quality components, the line meets the production needs of the dairy, juice, and flavored water industries. Thanks to its ability to process up to 36000 bottles per hour for the 500 ml format, it provides an excellent option for companies seeking robust and high-quality machines for bottling contamination-sensitive products. Ultimately, Used aseptic line KRONES stands out as a reliable choice for ensuring high-quality production.

Its ability to produce a wide range of aseptic cold-filled products, such as NFC juices, plant-based drinks like almond and oat milk, and even carbonated beverages, further broadens its application scope, making it a versatile investment for future market trends.