Description

Used Heating Tunnel Omar R&G HTD12 year 2017 up to 12000 bph

Technical Specifications and Use of the heating tunnel HTD12

The Used Heating Tunnel Omar R&G HTD12 year 2017 up to 12000 bph heats bottles using a hot water system, which makes it ideal for applications in the bottling industry. Moreover, this heating tunnel performs reliably and includes advanced technical features. It handles cylindrical bottles of various sizes while ensuring high efficiency and operational precision.

Technical Specifications of the Used Heating Tunnel

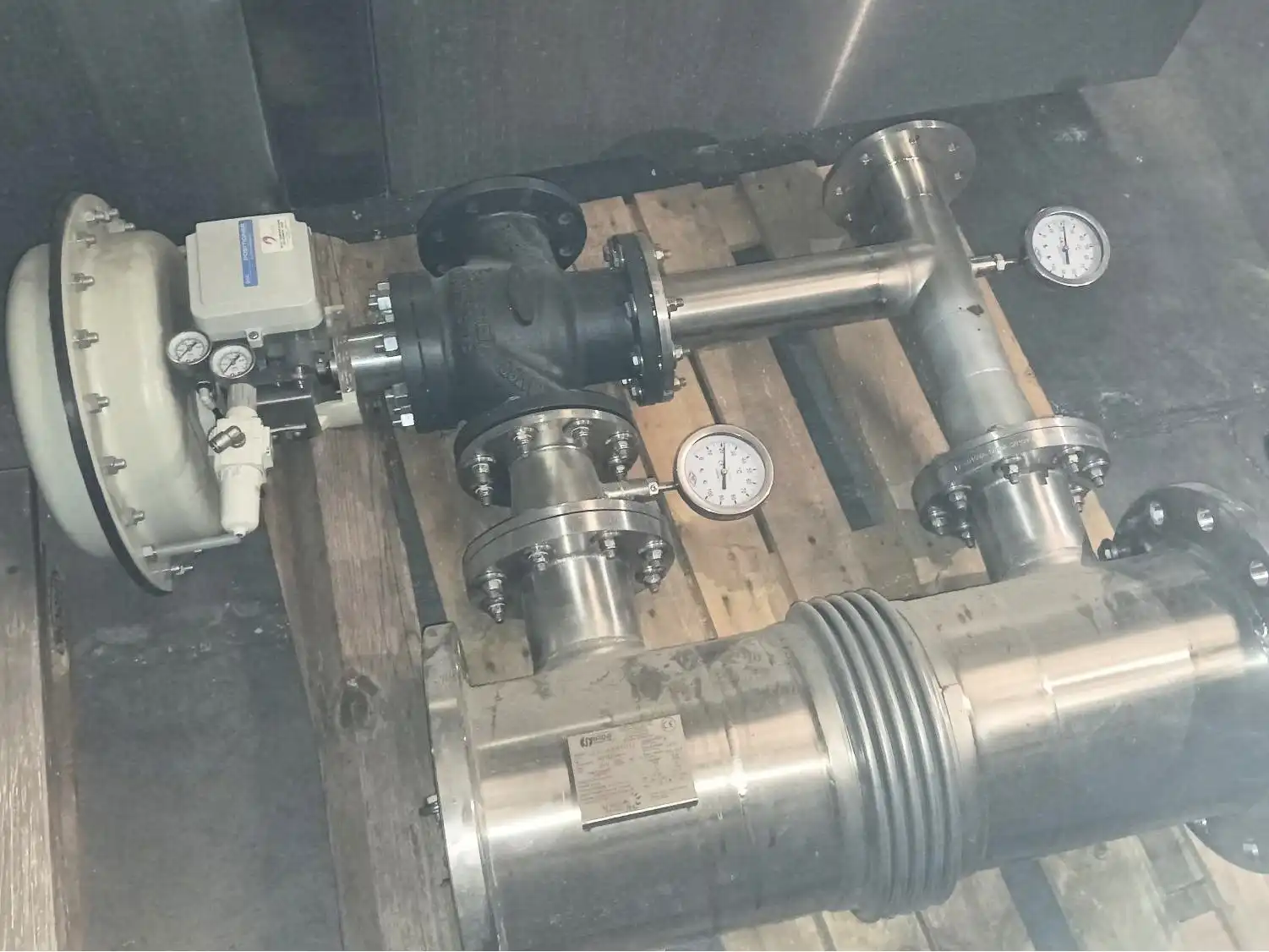

The used heating tunnel employs a hot water heat exchanger, and users need to supply hot water through a gas boiler. Consequently, this setup heats the bottles uniformly and optimizes the workflow. Additionally, the recycling pump and dryer consume 53 kW of energy, which ensures energy efficiency while maintaining high performance.

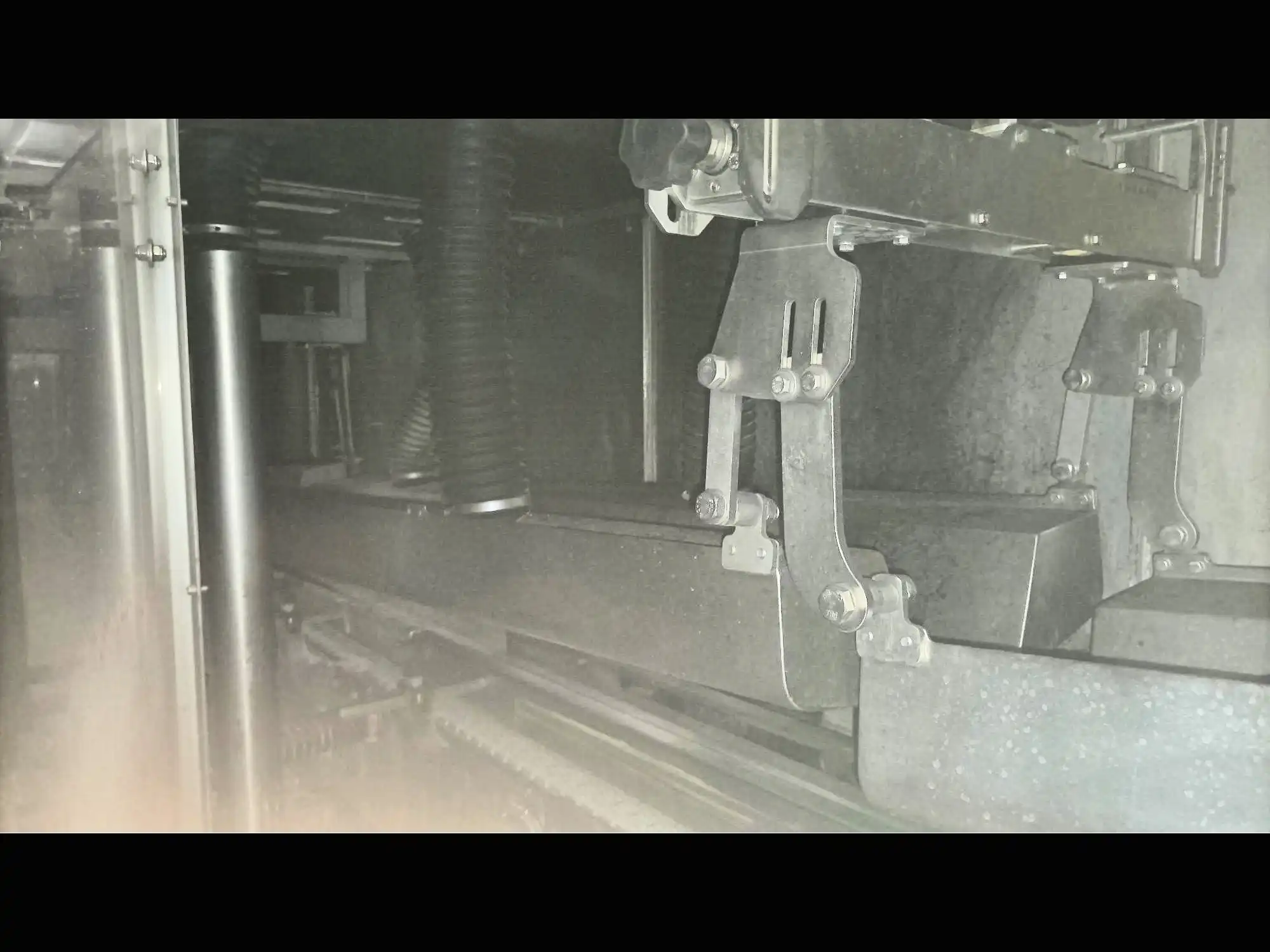

Furthermore, the used heating tunnel processes 12000 bottles per hour (bph), which makes it particularly suitable for high-speed bottling lines. Its FIFO (First In First Out) single-file system organizes bottles into a continuous and orderly flow. As a result, the system ensures consistent thermal treatment.

In terms of compatibility, the machine handles cylindrical bottles with diameters ranging from 60 mm to 100 mm. Therefore, it provides versatility for different formats and types of containers. Additionally, the tunnel operates counterclockwise (right-to-left), which suits specific production layout requirements.

Usage Conditions and Manufacturing Details

The heating tunnel HTD12 operates in an “as-is” condition, so buyers must inspect the machine thoroughly before purchase. Notably, the manufacturer built this model in 2017, delivering a reliable and high-quality solution for integrating a heating tunnel into production lines.

Omar R&G, a company renowned for producing high-quality machinery for the bottling industry, designed the HTD12 model to withstand intensive use. Consequently, it maintains operational reliability even in demanding environments.

Technical and Functional Advantages

The hot water heat exchanger delivers precise temperature control, which ensures uniform bottle heating. Moreover, the FIFO system keeps bottles in their entry order, which minimizes delays or errors during processing.

In addition, the modular design and optimized layout simplify maintenance. Users can, therefore, integrate the tunnel quickly into existing lines. Furthermore, the system accommodates bottles of different diameters, providing versatility for diverse industrial applications.

Conclusion of the Heating Tunnel HTD12

The Used Heating Tunnel Omar R&G HTD12 year 2017 up to 12000 bph provides a high-performing, reliable, and versatile solution for bottle heating. Moreover, the machine processes 12,000 bph, organizes bottles efficiently using the FIFO system, and supports various formats. Consequently, it proves to be an excellent choice for high-productivity bottling lines.

Thus, this HTD12 model by Omar R&G combines high performance with operational simplicity. As a result, it becomes a solid choice for industry professionals who seek reliability and efficiency. Therefore, for companies that prioritize productivity and precision, this machine represents a long-term investment.