Description

Used Capping Machine AROL T stopper year 2006

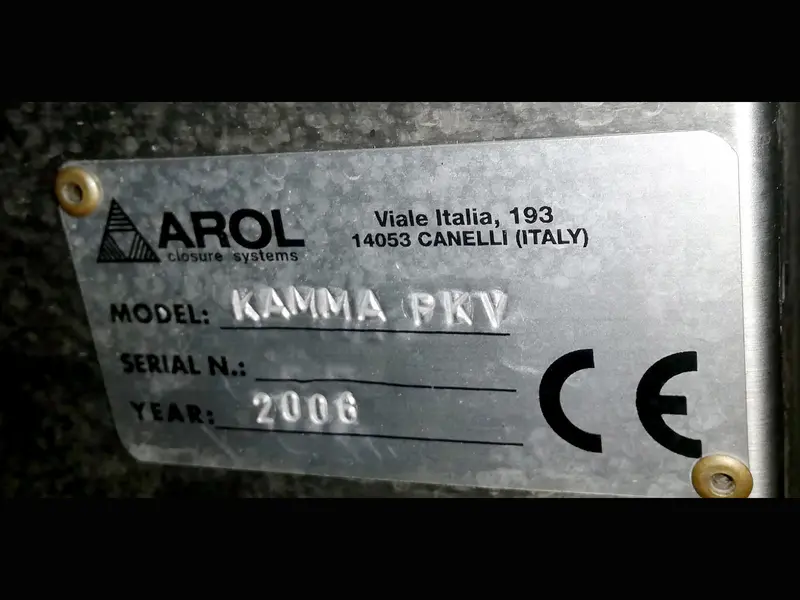

Machine Description of the Capper AROL KAMMA PKV

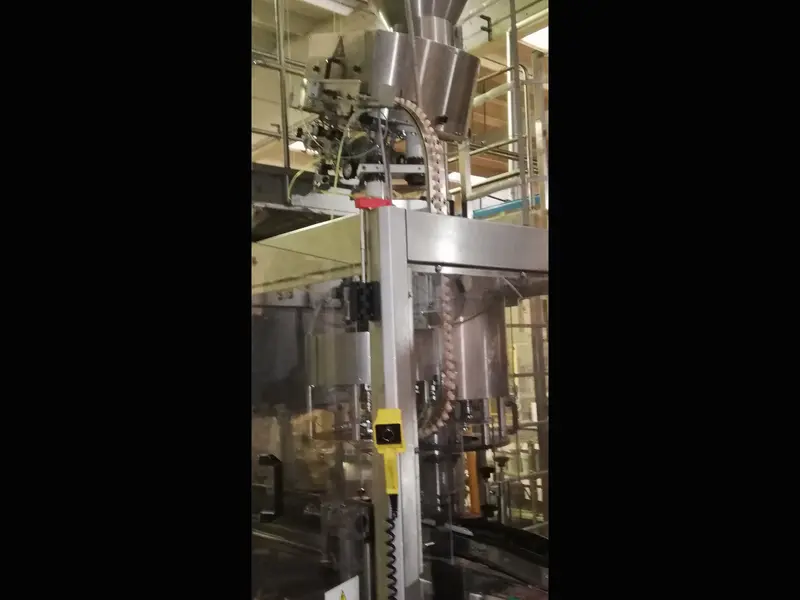

The machine is specifically designed for efficient and reliable bottling with T-stoppers in industrial settings. With its five heads, the machine precisely manages each step of the process. Consequently, it maintains closure quality consistently while operating at high production speeds.

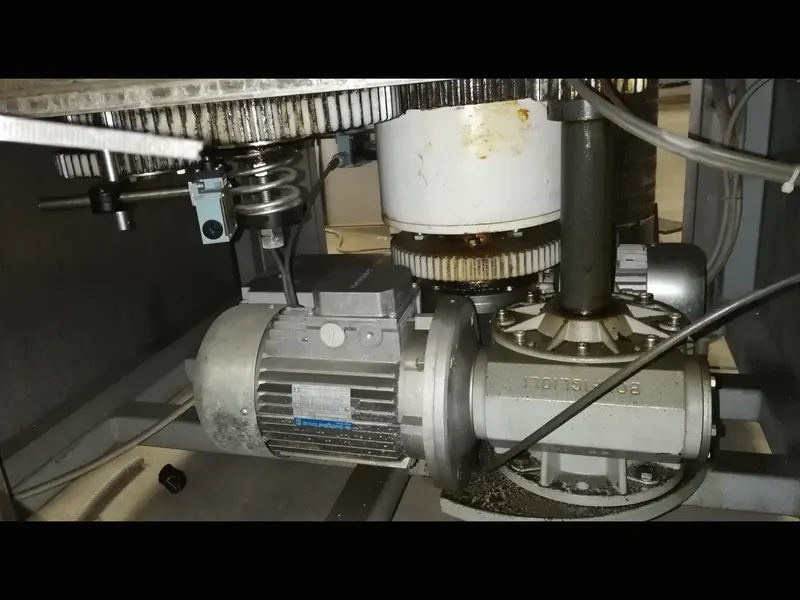

Cap Gripping System

To ensure effective stability during cap positioning, the machine’s vacuum-based gripping system secures each cap, which significantly reduces the risk of errors or misalignment. Moreover, an integrated vacuum pump powers this mechanism, ensuring a firm and consistent grip on each cap throughout the process.

Adjustable Capping Head

One key advantage of the AROL capping machine is its adjustable-height capping head, which easily adapts to various bottle sizes. As a result, this versatility makes the machine suitable for different production formats. Therefore, it increases both efficiency and operational flexibility.

Cap Distribution System

An alveolar centrifugal distributor manages cap distribution, ensuring uniform and consistent delivery. Furthermore, this component minimizes the risk of jamming. Thus, it keeps the workflow continuous, which is essential for maintaining high and uninterrupted production.

Safety and Materials

The Used Capping Machine AROL T stopper year 2006 includes safety guards, which effectively protect operators throughout operation. Additionally, the machine’s stainless steel exterior provides strength and corrosion resistance, which are both critical for use in the food and beverage industries.

Production Speed and Inverter Control

Thanks to its inverter control, operators can easily adjust the machine’s speed, allowing it to meet specific production demands. Consequently, the AROL capping machine can reach a production capacity of approximately 7,000 bottles per hour. Thus, it offers an ideal combination of efficiency and flexibility to satisfy market needs.

Bottle Flow Configuration

With its left-to-right bottle feed (clockwise flow), the machine optimizes the production line layout. This setup, therefore, integrates smoothly into existing systems, reducing installation time. In turn, it supports continuous production and maximizes operational efficiency.

Production Year of the Capper AROL KAMMA PKV

Manufactured in 2006, the Used Capping Machine AROL T stopper combines reliability with proven technology. Even though it was produced years ago, the machine still upholds high-quality standards. Hence, it offers companies a reliable and versatile capping solution.