Description

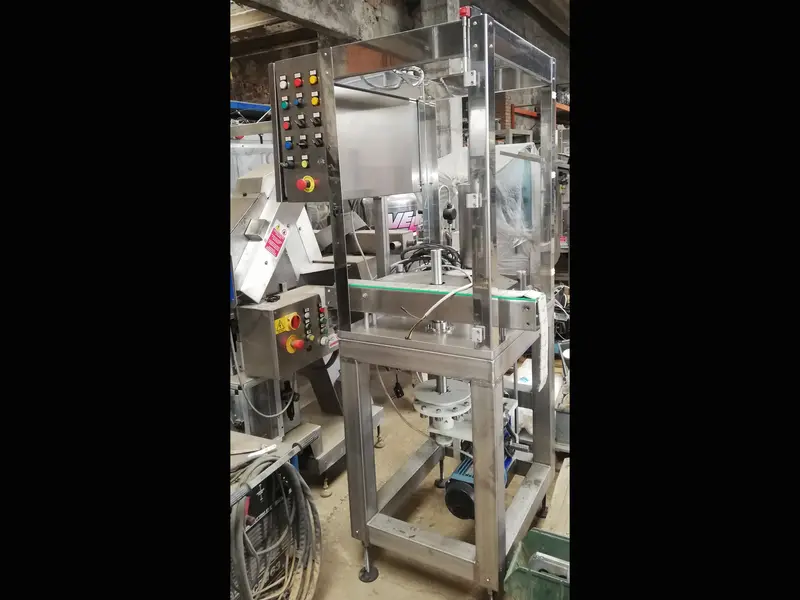

Used Capping Machine DAL TOSO T1DX 2000 bph

This machine effectively meets specific requirements for bottling and capping cylindrical bottles. DAL TOSO, therefore, designed this machine with a single-head system for aluminum screw caps, which ensures strong and precise capping operations. Moreover, the four-roller capping heads create uniform seals, thus reducing the chance of cap deformation.

Structural Features of the Used Capping Machine DAL TOSO T1DX 2000 bph

The Machine, on one hand, uses stainless steel throughout its construction to maximize durability and resistance. Its frame and coverings, also in stainless steel, simplify cleaning and prevent corrosion; consequently, it is ideal for intensive production environments. Furthermore, the machine positions the bottle entry on the right, which optimizes workflow, especially for users of cylindrical bottles. Additionally, its vibrating cap distributor reliably delivers caps without interruptions.

Production Performance

This capper offers variable production speeds, which operators can, therefore, adjust through a belt variator. As a result, this machine reaches a production capacity of up to 2,000 bottles per hour, making it suitable for medium-sized production lines. By adjusting the speed, users can control production flow precisely and, thus, adapt to different operational needs, which further optimizes process efficiency.

Safety and Standards of the used capping equipment

The machine complies with CE standards and, for this reason, prioritizes safety. It surrounds operators with protective guards along the entire perimeter to create a safe working environment and, consequently, prevent accidents. Moreover, the machine’s control panel, made of stainless steel, operates its electrical components at 380V three-phase with neutral and 50 Hz frequency, thus ensuring both reliability and compliance with European standards.

Year of Manufacture and Overhaul

Manufactured in 2007, the used capping equipment has undergone a complete overhaul, which restores its functionality to near-new condition. Moreover, the machine is set up to handle 30 x H 25 caps, making it, therefore, compatible with standard sizes. The capping machine already has the cylindrical bottle format configured; therefore, users can integrate it directly into their production cycle.

Applications and Industry Benefits

Ultimately, the Used Capping Machine DAL TOSO T1DX 2000 bph offers an efficient solution for companies seeking a fast and reliable capping process. Consequently, its robust design and advanced features help companies streamline production times and, in turn, improve seal quality. This, in effect, ensures product durability while minimizing maintenance needs.