Description

Used Homogeniser High Pressure Tetra Pak 10000 lhr

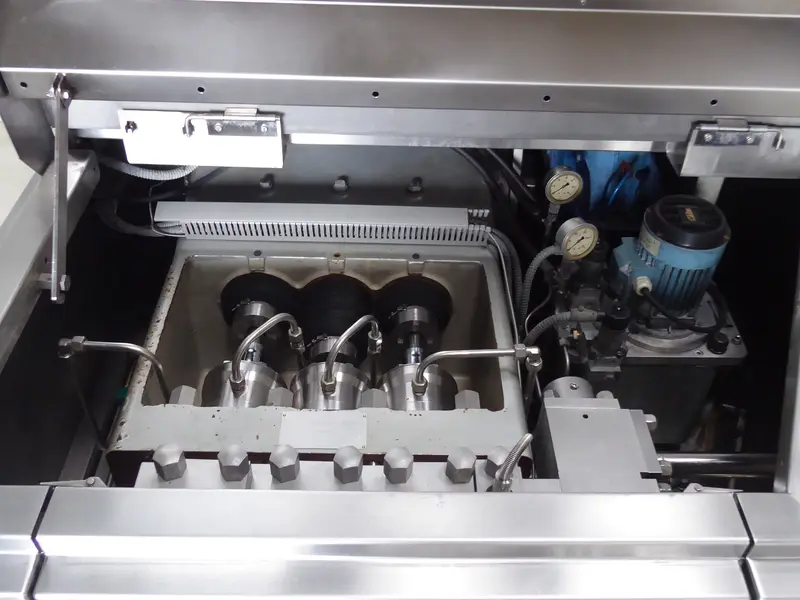

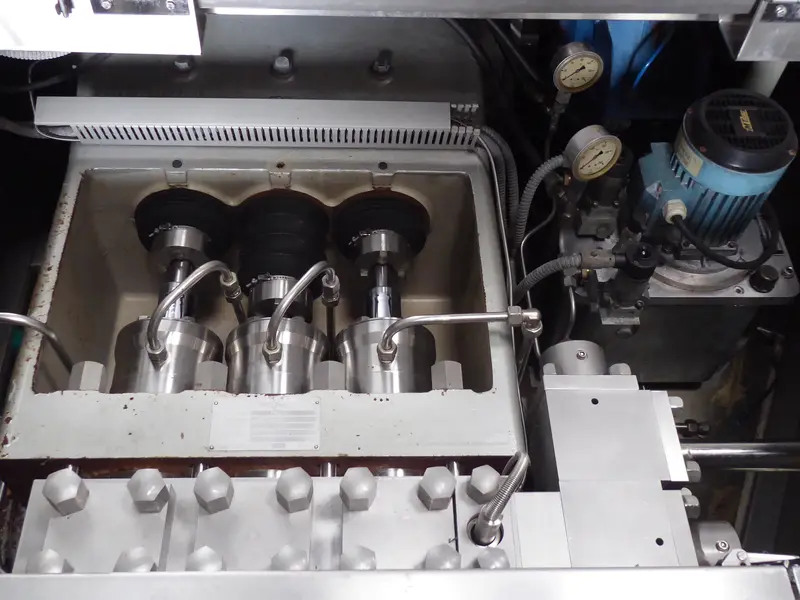

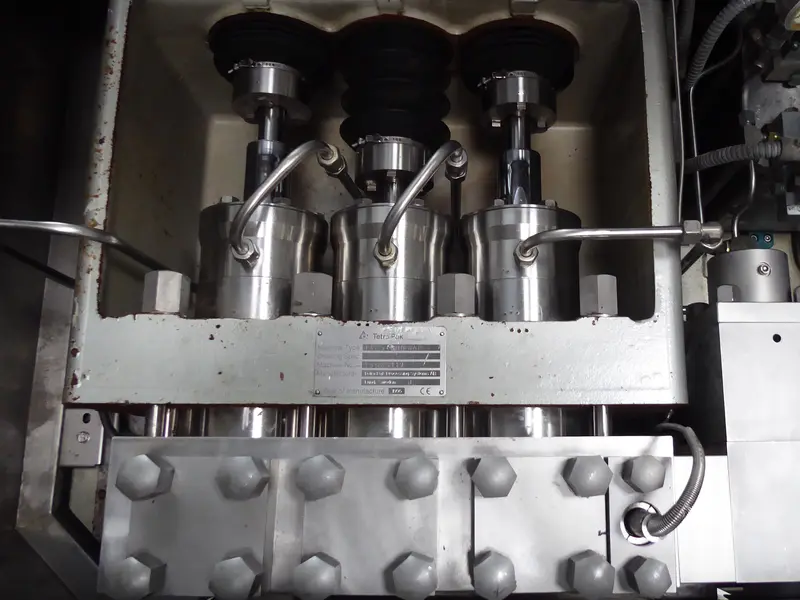

Main technical features of the Tetra Pak Homogeniser Alex TA25

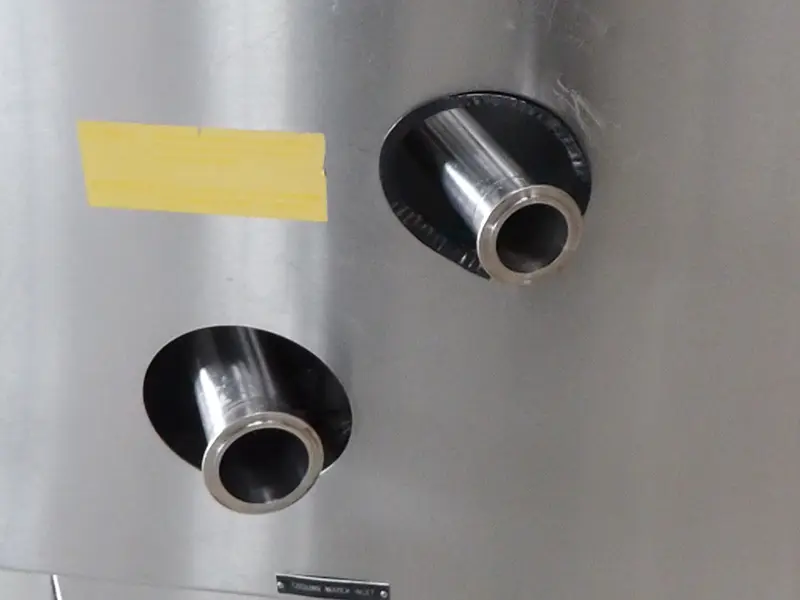

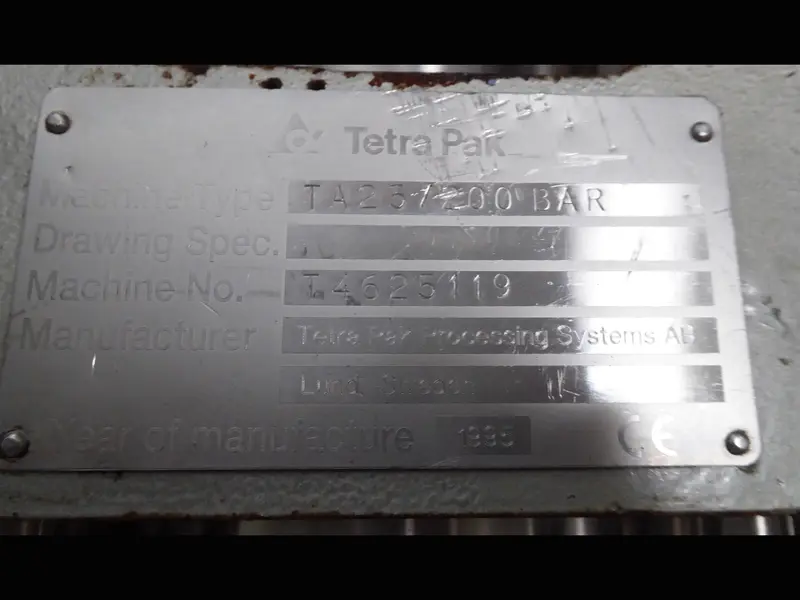

Tetra Pak manufactured the TA25/200BAR model in 1995 as a used high-pressure homogeniser, designed to process up to 10,000 liters per hour at a pressure of 200 bar. Currently, the machine operates at a capacity of 10,000 liters per hour, while maintaining a maximum pressure of 200 bar. In addition, the machine includes two homogenization stages, which are perfect for precise particle size reduction.

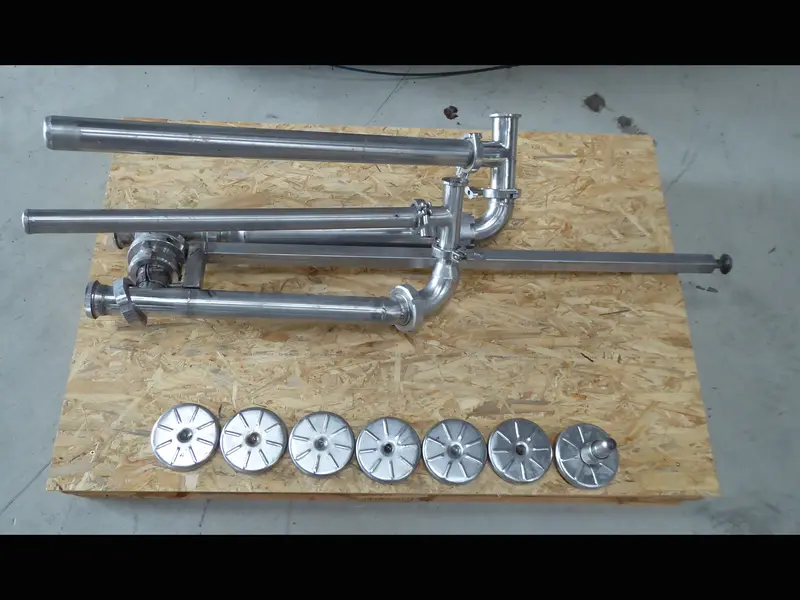

Components and operation

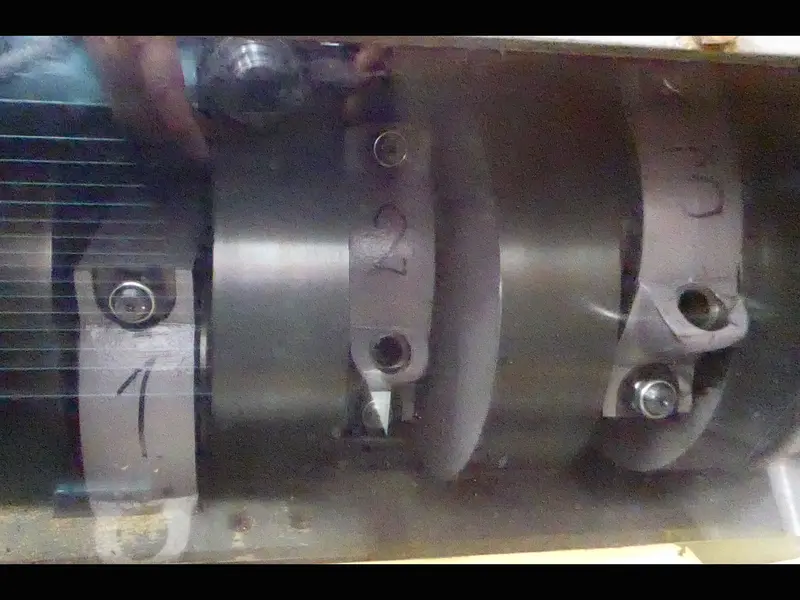

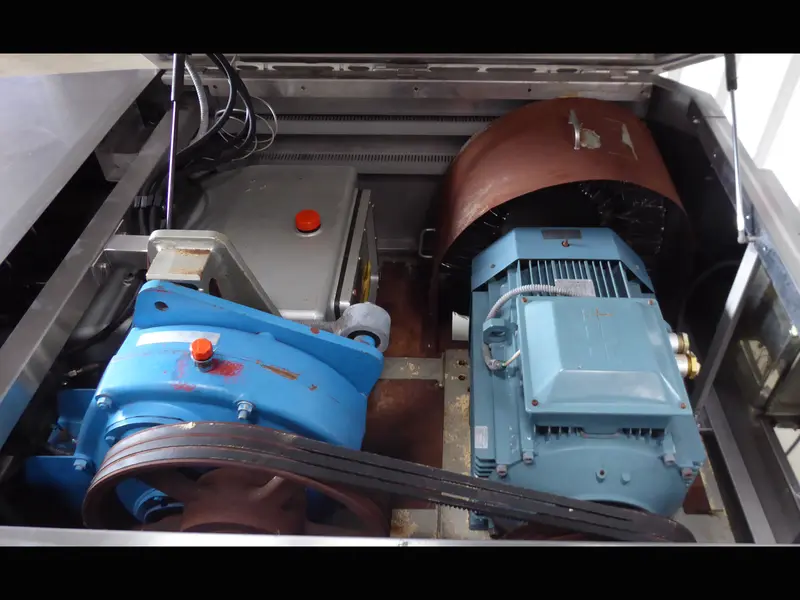

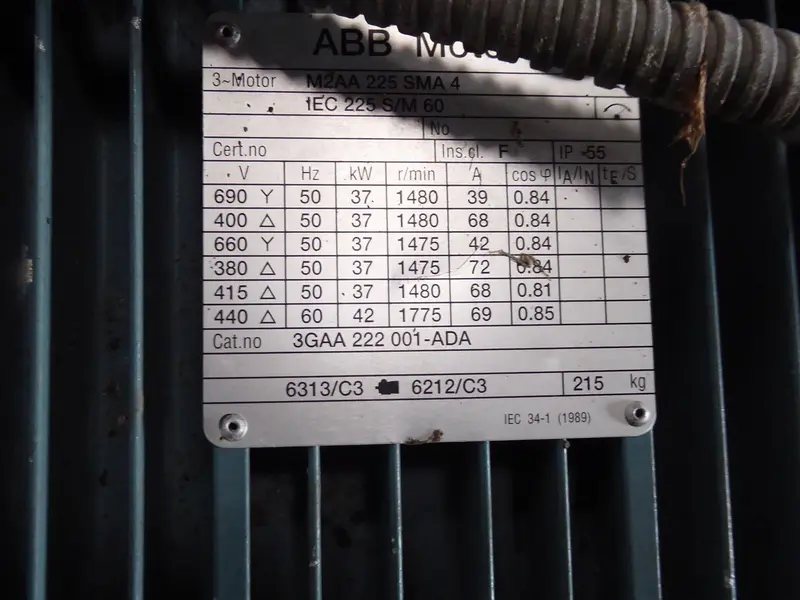

The Tetra Pak TA25/200BAR uses mushroom valve cylinders, which therefore ensure efficient control of liquid flow. The pistons have a diameter of 50 mm, which consequently allows the machine to evenly distribute pressure across the two stages. Moreover, a 37 kW motor powers the unit, with an input of 400 V, drawing 68 Amps, running at 50 Hz and 1480 rpm.

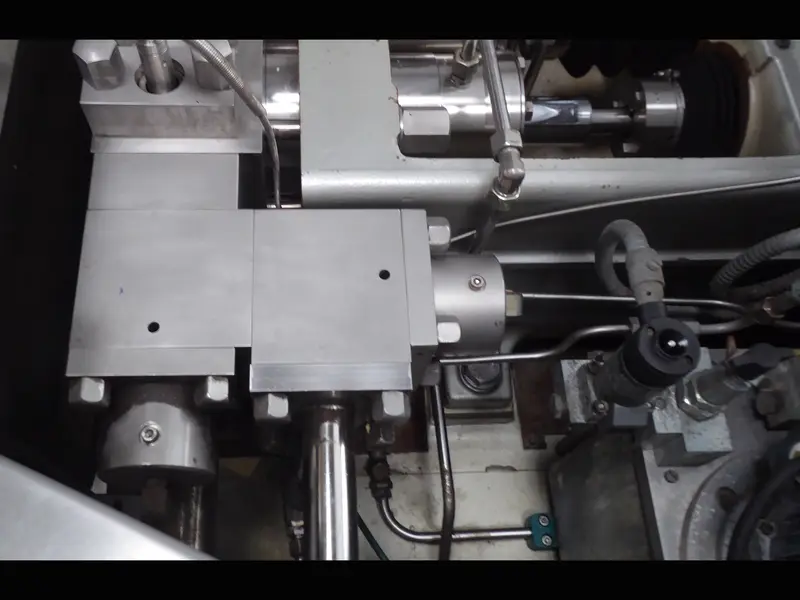

Dimensions and mechanical configuration

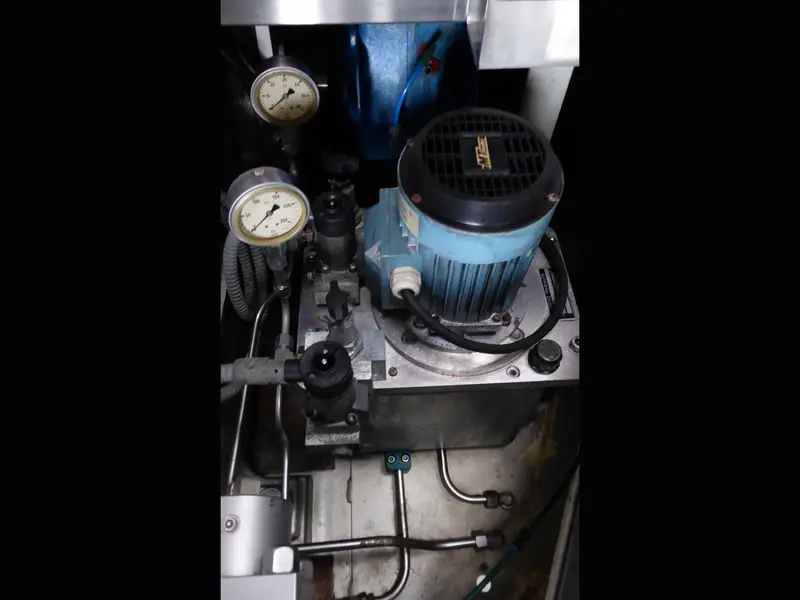

The Tetra Pak Homogeniser Alex TA25 measures 245 x 165 x 160 cm and weighs about 1,925 kg, which thus ensures stability during operation and simplifies installation in industrial facilities. Furthermore, the internal oil pumping system enhances the machine’s reliability, reducing the need for frequent maintenance.

Materials and construction of the Tetra Pak Homogeniser Alex TA25

The machine’s stainless steel cladding provides corrosion resistance, ensuring a long operational life. Additionally, the integrated pulsation damper optimizes process control, thereby reducing pressure variations that might affect product quality.

Applications and operational advantages

This Tetra Pak Homogeniser Alex TA25 is particularly suited for the food and beverage industry, where particle size reduction is crucial for product stability and consistency. Due to the two-stage configuration, it handles high-viscosity liquids effectively. As a result, it ensures uniform particle distribution. Thus, it provides optimal performance for various industrial applications.